I-Indium tin oxide (I-Indium Tin Oxide, ebizwa ngokuthi i-ITO) iyigebe elibanzi lebhendi, izinto ezisetshenziswa kakhulu ze-n-type semiconductor, ezinokudluliswa kokukhanya okuphezulu okubonakalayo kanye nezici zokumelana nokumelana, futhi ngaleyo ndlela isetshenziswa kabanzi kumaseli elanga, imibukiso yamaphaneli ayisicaba, amafasitela e-electrochromic, i-inorganic kanye ne-organic thin-film-film-electroluminescence kanye nezinye izisetshenziswa ze-laser divoltao. izindlela eziningi zokulungiselela amafilimu e-ITO, okuhlanganisa i-pulsed laser deposition, sputtering, chemical vapor deposition, spray decomposition thermal, sol-gel, ukuhwamuka, njll. Phakathi kwendlela yokuhwamuka, evame ukusetshenziswa kakhulu ukuhwamuka kwe-electron beam.

Kunezindlela eziningi zokulungisa ifilimu ye-ITO, okuhlanganisa ukuchithwa kwe-laser pulsed, sputtering, chemical vapor deposition, spray pyrolysis, sol-gel, ukuhwamuka nokunye, lapho indlela evame ukusetshenziswa kakhulu yokuhwamuka iwukuhwamuka kwe-electron beam. Ukulungiswa kokuhwamuka kwamafilimu e-ITO ngokuvamile kunezindlela ezimbili: eyodwa ukusetshenziswa kwe-high-purity In, i-Sn ingxubevange njengomthombo wezinto ezibonakalayo, emkhathini we-oksijini wokuhwamuka kokusabela; okwesibili ukusetshenziswa kokuhlanzeka okuphezulu kwe-In2O3:, ingxube ye-SnO2 njengomthombo wezinto zokuhwamuka okuqondile. Ukuze kwenziwe ifilimu nge-transmittance ephezulu kanye ne-resistivity ephansi, ngokuvamile idinga izinga lokushisa eliphezulu le-substrate noma isidingo sokudonsa okulandelayo kwefilimu. U-HR Fallah et al. isebenzise indlela yokuhwamuka kwe-electron beam emazingeni okushisa aphansi ukuze ifake amafilimu amancanyana e-ITO, ukufunda umthelela wezinga lokubeka, izinga lokushisa le-annealing kanye neminye imingcele yenqubo esakhiweni sefilimu, izakhiwo zikagesi nezokubona. Baveze ukuthi ukwehlisa izinga le-deposit kungakhuphula ukudluliswa kwe-transmittance futhi kunciphise ukumelana kwamafilimu akhule ngokwezinga lokushisa eliphansi. Ukudluliswa kokukhanya okubonakalayo kungaphezu kuka-92%, futhi ukumelana no-7X10-4Ωcm. babambe amafilimu e-ITO akhule kuzinga lokushisa legumbi elingu-350~550℃, futhi bathola ukuthi ukuphakama kwezinga lokushisa le-anneal, kuba ngcono indawo ecwebezelayo yamafilimu e-TO. ukukhanya okubonakalayo okudluliswa kwamafilimu ngemva kokufakwa kwe-anneal ku-550 ℃ kungu-93%, futhi usayizi wokusanhlamvu cishe u-37nm. indlela yokusiza i-plasma nayo inganciphisa izinga lokushisa le-substrate ngesikhathi sokubunjwa kwefilimu, okuyinto ebaluleke kakhulu ekubunjweni kwefilimu, futhi i-crystallinity nayo ibaluleke kakhulu. Indlela yokusiza nge-plasma inganciphisa izinga lokushisa le-substrate ngesikhathi sokubunjwa kwefilimu, futhi ifilimu ye-ITO etholwe ekufakweni inokusebenza okuhle. ukuphikiswa kwefilimu ye-ITO elungiswe ngu-S. Laux et al. iphansi kakhulu, i-5 * 10-”Ωcm, futhi ukumuncwa kokukhanya ku-550nm kungaphansi kuka-5%, futhi ukumelana kwefilimu nomkhawulokudonsa obonakalayo nakho kushintshwa ngokushintsha ingcindezi ye-oxygen ngesikhathi sokubekwa.

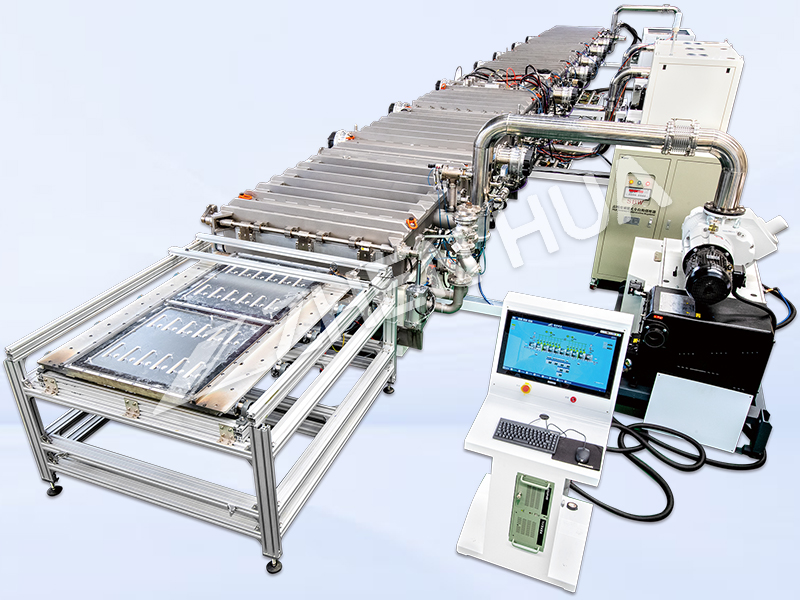

-Le ndatshana ikhishwe nguumenzi womshini we-vacuum coatingI-Guangdong Zhenhua

Isikhathi sokuthumela: Mar-23-2024