I-Indium tin oxide (i-Indium Tin Oxide, ebizwa ngokuba yi-ITO) yi-gap band ebanzi, i-doped kakhulu ye-n-type semiconductor materials, kunye nokuhanjiswa kokukhanya okuphezulu okubonakalayo kunye neempawu eziphantsi zokuxhathisa, kwaye ngaloo ndlela isetyenziswa ngokubanzi kwiiseli zelanga, i-flat panel displays, iifestile ze-electrochromic, i-inorganic and organic thin-film-film electroluminescence kunye nezinye izixhobo ze-photovoltaic electroluminescence kunye nezinye izixhobo ze-photovoltaic laser. iindlela ezininzi zokulungiselela iifilimu ze-ITO, kuquka i-pulsed laser deposition, i-sputtering, i-chemical vapor deposition, i-spray i-thermal decomposition, i-sol-gel, i-evaporation, njl.

Zininzi iindlela zokulungiselela ifilimu ye-ITO, kubandakanywa ukuchithwa kwe-laser ye-pulsed, i-sputtering, i-chemical vapor deposition, i-spray pyrolysis, i-sol-gel, i-evaporation kunye nokunye, apho eyona ndlela ixhaphakileyo esetyenziswayo yokukhupha umphunga i-electron beam evaporation. Ukulungiswa kwe-Evaporation yeefilimu ze-ITO ngokuqhelekileyo zineendlela ezimbini: enye kukusetyenziswa kwe-high-purity In, i-Sn i-alloy njengomthombo wezinto, kwi-atmosphere ye-oksijini ye-reaction evaporation; okwesibini kukusetyenziswa kobunyulu obuphezulu be-In2O3 :, umxube we-SnO2 njengomthombo wezinto zokukhupha ngokuthe ngqo. Ukuze wenze ifilimu nge-transmittance ephezulu kunye ne-resistivity ephantsi, ngokubanzi ifuna iqondo lokushisa eliphezulu le-substrate okanye imfuno yokuhlanjululwa kwefilimu elandelayo. UHR Fallah et al. wasebenzisa indlela electron umqadi evaporation kumaqondo obushushu aphantsi idipozithi ITO films obhityileyo, ukufunda isiphumo iqondo lokubeka, ubushushu annealing kunye nezinye iiparameters inkqubo kwisakhiwo ifilimu, iimpawu zombane kunye optical. Baye bachaza ukuba ukwehlisa inqanaba lokubekwa kunokunyusa ukuhanjiswa kunye nokunciphisa ukumelana neefilimu ezikhule ngokuphantsi. Ukuhanjiswa kokukhanya okubonakalayo kungaphezulu kwe-92%, kwaye ukuxhathisa yi-7X10-4Ωcm. baye bavala iifilimu ze-ITO ezikhule kwiqondo lobushushu legumbi kwi-350~550℃, kwaye bafumanisa ukuba xa uphezulu ubushushu be-annealing, kokukhona ipropathi eyikristale yeefilimu ze-ITO. ukuhanjiswa kokukhanya okubonakalayo kweefilimu emva kokunyuswa kwe-550 ℃ yi-93%, kunye nobukhulu beenkozo malunga ne-37nm. indlela yokuncedisa i-plasma inokunciphisa ukushisa kwe-substrate ngexesha lokubunjwa kwefilimu, eyona nto ibalulekileyo ekubunjweni kwefilimu, kwaye i-crystallinity nayo ibaluleke kakhulu. Indlela yokuncedisa i-plasma inokunciphisa ukushisa kwe-substrate ngexesha lokubunjwa kwefilimu, kwaye ifilimu ye-ITO efunyenwe kwi-deposition inokusebenza kakuhle. ukuxhathisa kwefilimu ye-ITO elungiselelwe ngu-S. Laux et al. iphantsi kakhulu, i-5 * 10- ”Ωcm, kwaye ukufunxwa kokukhanya kwi-550nm kungaphantsi kwe-5%, kwaye i-resistantivity yefilimu kunye ne-bandwidth ye-optical nayo itshintshiwe ngokuguqula uxinzelelo lwe-oksijini ngexesha lokubeka.

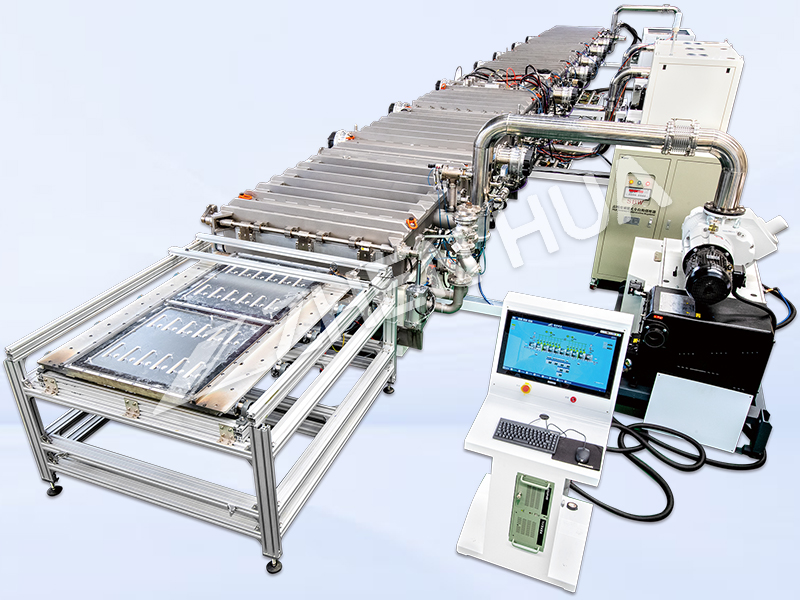

–Eli nqaku likhutshwa nguumenzi womatshini wokugqumaGuangdong Zhenhua

Ixesha lokuposa: Mar-23-2024