Indium tin oxide (Indium Tin Oxide, loo yaqaan ITO) waa farqiga band ballaaran, si xoog leh doped n-nooca semiconductor maaddooyinka, oo leh gudbinta iftiinka sare muuqda iyo sifooyinka iska caabin hoose, oo sidaas daraaddeed si ballaaran loo isticmaalo in unugyada qoraxda, bandhigay panel flat, electrochromic daaqadaha, inorganic iyo organic khafiif-film electroluminescence, qayb ka mid ah iyo organic dhuuban-film electroluminescence, diodets laser iyo qalab kale oo badan. diyaarinta filimada ITO, oo ay ku jiraan dhigista laser garaaca, sputtering, kaydinta uumiga kiimikaad, buufin burburka kulaylka, sol-gel, uumiga, iwm ka mid ah habka uumi-baxa, inta badan la isticmaalo waa uumi alwaax elektaroonik ah.

Waxaa jira siyaabo badan oo loo diyaariyo filimka ITO, oo ay ku jiraan kaydinta laser garaaca, sputtering, kaydinta uumiga kiimikada, buufinta pyrolysis, sol-gel, uumiga iyo wixii la mid ah, kuwaas oo habka ugu badan ee loo isticmaalo uumiga uumi waa koronto. Diyaarinta uumi-baxa ee filimada ITO sida caadiga ah waxay leeyihiin laba siyaabood: mid waa isticmaalka nadiifinta sare ee In, Sn alloy sida walxaha isha, jawiga oksijiinta ee uumiga falcelinta; Midda labaad waa isticmaalka nadiifinta sare ee In2O3:, SnO2 isku dar ah oo ah walxaha isha ee uumiga tooska ah. Si loo sameeyo filimka oo leh gudbin sare iyo iska caabin hooseeya, guud ahaan waxay u baahan yihiin heerkul sare oo substrate ah ama baahida loo qabo in filimka dambe la tirtiro. HR Fallah iyo al. loo isticmaalo habka uumi-baxa elektarooniga ah heerkulka hooseeya si loo dhigo filimada khafiifka ah ee ITO, si loo barto saameynta heerka kaydinta, heerkulka annealing iyo hababka kale ee habka qaab dhismeedka filimka, guryaha korontada iyo indhaha. Waxay tilmaameen in hoos u dhigista heerka kaydinta ay kordhin karto gudbinta iyo hoos u dhigista iska caabbinta filimada heerkulka hooseeya. Gudbinta iftiinka muuqda ayaa ka badan 92%, iska caabintuna waa 7X10-4Ωcm. Waxay tirtireen filimadii ITO ee ku koray heerkulka qolka 350 ~ 550 ℃, waxayna ogaadeen in heerkulka kor u kaca uu yahay, ka sii fiican hantida crystalline ee filimada ITO. gudbinta iftiinka muuqda ee filimada ka dib markii la tirtiro at 550 ℃ waa 93%, iyo cabbirka hadhuudhku waa qiyaastii 37nm. Habka Plasma-caawinta ayaa sidoo kale hoos u dhigi kara heerkulka substrate inta lagu jiro sameynta filimka, taas oo ah qodobka ugu muhiimsan ee sameynta filimka, iyo crystallinity sidoo kale waa tan ugu muhiimsan. Habka plazma-caawinta ayaa sidoo kale hoos u dhigi kara heerkulka substrate inta lagu jiro sameynta filimka, iyo filimka ITO ee laga helay meelaynta ayaa leh waxqabad wanaagsan. iska caabinta filimka ITO ee ay diyaariyeen S. Laux et al. waa mid aad u hooseeya, 5 * 10-"Ωcm, iyo nuugista iftiinka ee 550nm waa wax ka yar 5%, iyo iska caabinta filimka iyo xajmiga indhaha ayaa sidoo kale la beddelaa iyadoo la beddelayo cadaadiska oksijiinta inta lagu jiro kaydinta.

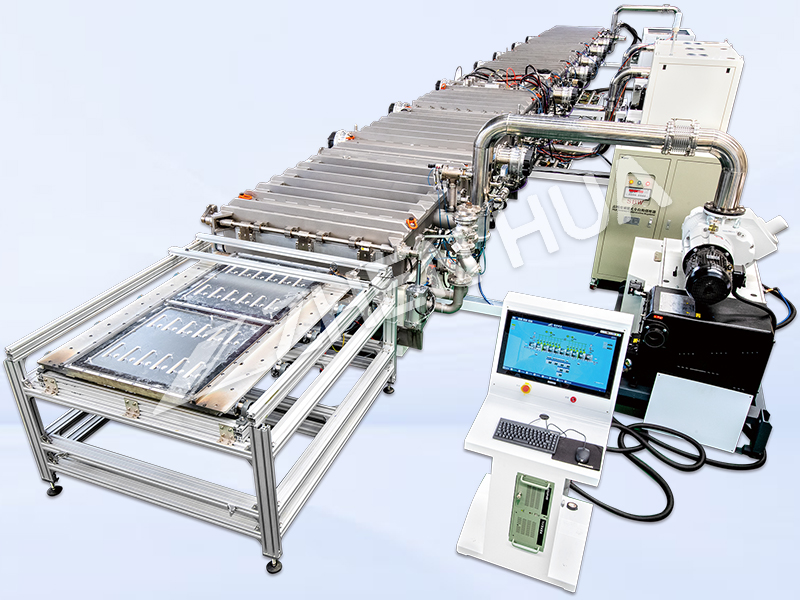

–Maqaalkan waxa soo saaraysoo saaraha mashiinka daahan vacuumGuangdong Zhenhua

Waqtiga boostada: Mar-23-2024