Indium tin oxide (Indium Tin Oxide, ake magana a kai a matsayin ITO) ne mai fadi band rata, dauke da doped n-type semiconductor kayan, tare da high bayyane haske watsa da kuma low resistivity halaye, kuma haka yadu amfani a cikin hasken rana Kwayoyin, lebur panel nuni, electrochromic windows, inorganic da Organic bakin ciki-film electroluminescence, Laser diodets da sauran na'urorin ganowa da sauransu. na shirye-shiryen fina-finan ITO, ciki har da pulsed Laser jibo, sputtering, sinadaran tururi jibo, fesa thermal bazuwar, sol-gel, evaporation, da dai sauransu Daga cikin evaporation hanya, da aka fi amfani da electron katako evaporation.

Akwai hanyoyi da yawa don shirya fim ITO, ciki har da pulsed Laser jibo, sputtering, sinadaran tururi jibo, fesa pyrolysis, sol-gel, evaporation da sauransu, wanda aka fi amfani da evaporation hanya ne electron katako evaporation. Shirye-shiryen evaporation na fina-finai na ITO yawanci yana da hanyoyi guda biyu: daya shine amfani da tsabta mai tsabta A, Sn alloy a matsayin tushen kayan aiki, a cikin yanayin oxygen don ƙaddamar da amsawa; na biyu shine amfani da babban-tsarki In2O3:, SnO2 cakuda a matsayin tushen kayan don fitar da kai tsaye. Don yin fim ɗin tare da babban watsawa da ƙarancin juriya, gabaɗaya yana buƙatar ƙarin zafin jiki mafi girma ko buƙatar ƙarar fim ɗin gaba. HR Fallah et al. ya yi amfani da hanyar ƙafewar katako na lantarki a ƙananan yanayin zafi don saka fina-finai na ITO na bakin ciki, don nazarin tasirin adadin ajiya, zafin jiki da sauran sigogi na tsari akan tsarin fim, kayan lantarki da kayan gani. Sun yi nuni da cewa rage yawan adadin ajiya zai iya ƙara yawan watsawa da rage juriya na fina-finai masu ƙarancin zafi. Watsawar hasken da ake iya gani ya fi 92%, kuma juriya shine 7X10-4Ωcm. sun shafe fina-finai na ITO da aka girma a dakin da zafin jiki a 350 ~ 550 ℃, kuma sun gano cewa mafi girma da zafin jiki na annealing shine mafi kyawun kayan crystalline na fina-finai na ITO. isar da haske na bayyane na fina-finai bayan annashuwa a 550 ℃ shine 93%, kuma girman hatsi shine kusan 37nm. Hakanan hanyar da aka taimaka wa plasma na iya rage yawan zafin jiki a lokacin samar da fim, wanda shine mafi mahimmancin abu a cikin samuwar fim, kuma crystallinity shine mafi mahimmanci. Hakanan hanyar taimakon plasma na iya rage yawan zafin jiki a lokacin ƙirƙirar fim, kuma fim ɗin ITO da aka samu daga wurin ajiya yana da kyakkyawan aiki. da resistivity na ITO fim shirya ta S. Laux et al. yana da ƙananan ƙananan, 5 * 10-"Ωcm, kuma ɗaukar haske a 550nm bai wuce 5% ba, kuma ana canza tsayayyar fim din da bandwidth na gani ta hanyar canza matsa lamba na oxygen a lokacin ƙaddamarwa.

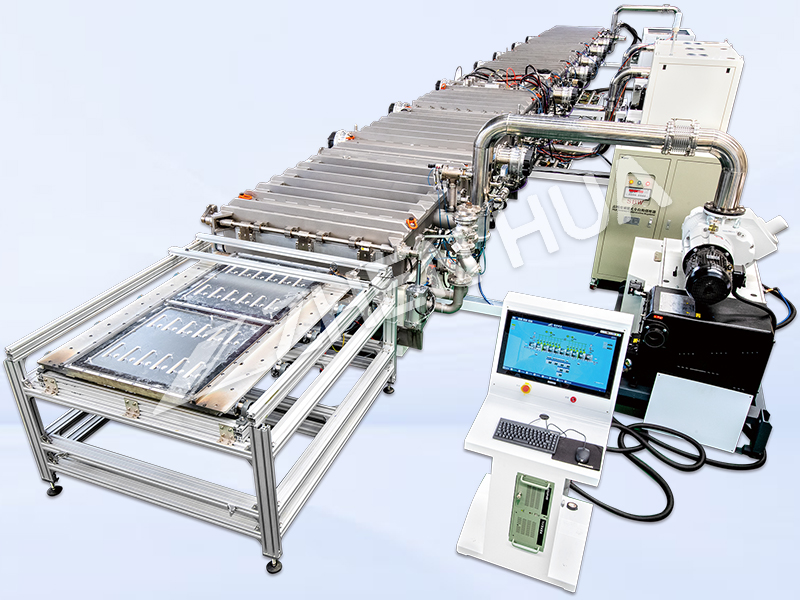

–An fitar da wannan labarininjin shafa injin injinGuangdong Zhenhua

Lokacin aikawa: Maris 23-2024