TLHALOSO EA SEHLAHISOA

Kamore ea ho roala seretse ea lisebelisoa tsa ho beha mouoane oa lik'hemik'hale o amohela sebopeho se ikemetseng sa mekhahlelo e 'meli ea ho pholisa metsi, se sebetsang hantle le se ts'oanelang ho pholisa, se nang le sebopeho se bolokehileng le se tsitsitseng. Thepa e entsoe ka mamati a mabeli, lifensetere tse ngata tsa ho shebella le li-interfaces tse ngata tsa katoloso, tse loketseng khokahano ea kantle ea lisebelisoa tse thusang joalo ka tekanyo ea mocheso oa infrared, tlhahlobo ea spectral, tlhahlobo ea video le thermocouple. Mohopolo o tsoetseng pele oa moralo o etsa hore ts'ebetso ea letsatsi le letsatsi le tlhokomelo, phetoho ea tlhophiso le ntlafatso ea thepa e be bonolo le e bonolo, 'me ka katleho e fokotsa litšenyehelo tsa tšebeliso le ho ntlafatsa.

Likarolo tsa lisebelisoa:

1. Likarolo tsa theko ea thepa haholo-holo li kenyelletsa metha ea phallo ea boima, valve ea solenoid le tanka ea ho kopanya khase, e netefatsang taolo e nepahetseng ea phallo ea khase ea ts'ebetso, ho kopanya junifomo le ho itšehla thajana ka mokhoa o sireletsehileng oa likhase tse fapaneng, 'me e ka khetha likarolo tsa sistimi ea khase bakeng sa tšebeliso ea mohloli oa khase ea mokelikeli, ho tsamaisa khetho ea motho ka mong ea mehloli e mengata ea khabone ea mokelikeli, le tšebeliso e bolokehileng ea mokelikeli oa mokelikeli oa mokelikeli oa boron.

2.Seboka sa ho ntša moea se na le pompo e khutsitseng le e sebetsang hantle ea rotary vane vacuum le tsamaiso ea pompo ea molek'hule ea turbo e ka kopanang ka potlako le tikoloho e phahameng ea vacuum. Sekhahla sa vacuum sa composite se nang le khanyetso le ionization gauge se sebelisetsoa tekanyo ea vacuum, hammoho le tsamaiso ea capacitive ea filimi e khonang ho lekanya khatello ea likhase tse fapaneng tsa ts'ebetso ka mefuta e mengata. Khatello ea li-deposition e laoloa ka ho feletseng ke valve ea taolo e nepahetseng ka ho fetisisa.

3.Karolo ea metsi a pholileng e na le khatello ea metsi a mangata, phallo, tekanyo ea mocheso le lisebelisoa tsa software. Likarolo tse fapaneng tsa ho pholile li ikemetse ho tse ling, tse loketseng ho hlahlojoa ha phoso ka potlako. Makala ohle a na le li-switches tsa valve tse ikemetseng, tse bolokehileng le tse sebetsang hantle.

4.Likarolo tsa ho laola motlakase li nka skrine ea LCD ea mochine oa motho oa boholo bo boholo 'me li sebelisana le PLC ea ho laola ka ho feletseng ho etsa hore ho be bonolo ho hlophisa le ho kenya mokhoa oa ts'ebetso. Grafiken Curve e bonts'a liphetoho le boleng ba liparamente tse fapaneng, 'me lisebelisoa le liparamente tsa ts'ebetso li rekotoa ka bo eona le ho bolokoa ho thusa ho latella mathata le tlhahlobo ea lipalo-palo.

5.The workpiece rack e na le servo motor ho laola ho phahamisa le ho theola tafole ea substrate. Tafole ea substrate ea graphite kapa e khubelu ea koporo e ka khethoa. Mocheso o lekanngoa ka thermocouple.

Likarolo tsa 6.The rack li ka etsoa ka kakaretso kapa ka thoko ho latela litlhoko tsa bareki ho fihlela litlhoko tse khethehileng tsa ho sebetsana le bareki.

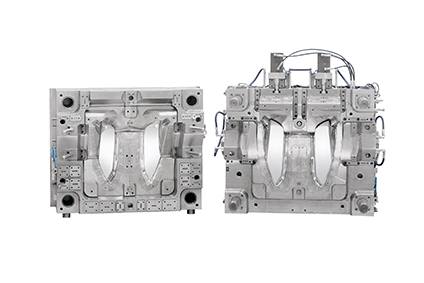

7.Likarolo tsa poleiti ea ho tiisa li ntle ebile li ntle. Lipoleiti tsa ho tiisa libakeng tse fapaneng tsa lisebelisoa tsa lisebelisoa li ka qhaqhoa ka potlako kapa tsa buloa 'me tsa koaloa ka bolokolohi, tse loketseng haholo ho li sebelisa.

Hot filament CVD thepa e loketse bakeng sa depositi thepa daemane, ho akarelletsa le filimi e tšesaane barbotage, ho intša tshehetsa filimi teteaneng, microcrystalline le nanocrystalline daemane, conductive taemane, joalo-joalo E haholo-holo e sebediswa bakeng sa ho apara manganga tšireletso barbotage ea cemented carbide seha lisebelisoa, thepa semiconductor tse kang silicon le silicon carbide, mocheso dissipation boronde coped ea disebediswa conductive electroozone. ho hloekisa metsi kapa likhoerekhoere.

| Mehlala ea boikhethelo | boholo ba kamore e ka hare |

| HFCVD0606 | φ600*H600(mm) |