I-Resistance evaporation source coating iyindlela eyisisekelo ye-vacuum evaporation coating. “Ukuhwamuka” kubhekisela endleleni yokulungiselela ifilimu elincanyana lapho okokunamathelayo kugumbi levacuum kushisiswe futhi kuhwamuke, ukuze ama-athomu abalulekile noma ama-molecule ahwamuke futhi aphume phezulu, enze isenzakalo sokugeleza komhwamuko, isigameko ebusweni be-substrate noma i-substrate, futhi ekugcineni ajikijelwe ukuze akhe ifilimu eqinile.

Okubizwa ngokuthi ukumelana evaporation umthombo enamathela indlela ukusebenzisa tantalum, molybdenum, tungsten kanye nezinye okusezingeni eliphezulu ukuncibilika izinsimbi ukwenza ijamo elifanele umthombo ukuhwamuka, okuyinto elayishwe izinto ukuba ahwamuke, ake umoya ugeleze ngokusebenzisa, ukushisa ngqo futhi ahwamuke izinto ehwamukayo, noma abeke izinto zokwakha ukuhwamuka ku-alumina, i-beryllium e-evaporation kanye ne-evaporation oxide. Lena yindlela yokuhwamuka kokushisa kokumelana.

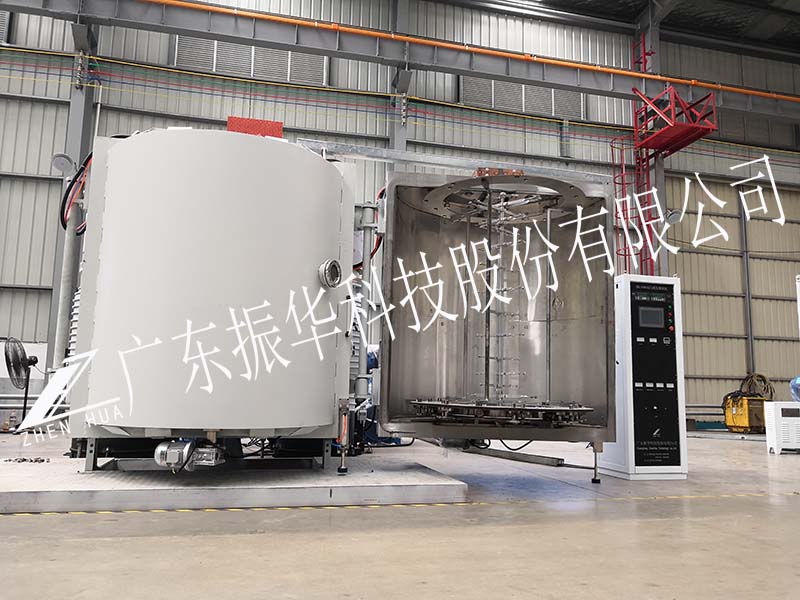

Iumshini wokugcwalisa i-vacuum evaporationukushisisa nokuhwamuka yi-heater yokumelana kunezinzuzo zesakhiwo esilula, izindleko eziphansi kanye nokusetshenziswa okuthembekile. Ingasetshenziselwa ukuhwamuka kwezinto ezinephuzu elincibilikayo eliphansi, ikakhulukazi ekukhiqizeni ngobuningi ngezidingo eziphansi zekhwalithi yokumboza. Kuze kube manje, kusekhona inqwaba yezinqubo zokumboza zokushisa kokumelana nokuhwamuka okusetshenziselwa ukukhiqizwa kwezibuko ze-aluminium.

Ukungalungi kwe-resistance evaporation source evaporation coating indlela yokuthi izinga lokushisa eliphezulu elingafinyelelwa ngokushisa lilinganiselwe, futhi impilo yesevisi ye-heater nayo ifushane. Eminyakeni yamuva nje, ukuze kuthuthukiswe impilo yomthombo wokuhwamuka kokumelana, ifekthri yemishini yamukele impahla yobumba eqhutshwayo ehlanganiswe yi-boron nitride enempilo ende njengomthombo wokuhwamuka. Ngokombiko welungelo lobunikazi waseJapane, ingasebenzisa izinto ezakhiwe nge-20% ~ 30% ye-boron nitride nezinto eziphikisayo ezingahlanganiswa nayo ukuze yenze umthombo wokuhwamuka (crucible), futhi imboze ubuso bayo ngongqimba lwe-zirconium equkethe u-62% ~ 82%, kanti okunye kuyi-zirconium-silicon alloy materials.

Isikhathi sokuthumela: Apr-22-2023