Lub tshuab nqus tsev ion txheej (xws li ion plating) yog Tebchaws Meskas hauv xyoo 1963 Somdia tuam txhab DM Mattox tau npaj tseg, xyoo 1970 tau tsim kho sai ntawm kev kho cov thev naus laus zis tshiab. Nws yog hais txog kev siv cov evaporation los yog sputtering lub hom phiaj nyob rau hauv lub tshuab nqus tsev cua kom cov ntaub ntawv evaporation los yog sputtering, evaporation los yog sputtering tawm ntawm ib feem ntawm cov hais nyob rau hauv cov pa paug qhov chaw ionized rau hauv hlau ions.

Cov khoom no tau muab tso rau ntawm lub substrate nyob rau hauv qhov kev txiav txim ntawm hluav taws xob teb los tsim cov txheej txheem nyias zaj duab xis.

Lub tshuab nqus tsev ion plating ntawm ntau yam, feem ntau raws li cov khoom siv membrane los tsim cov ion yuav muab faib ua ob hom: evaporation qhov chaw hom ion plating thiab sputtering hom phiaj hom ion plating. Cov qub yog evaporated los ntawm cua sov cov ntaub ntawv zaj duab xis los tsim cov hlau vapors, yog li ntawd nws yog ib feem ntawm ionized rau hauv cov hlau vapors thiab high-lub zog nruab nrab atoms nyob rau hauv qhov chaw ntawm cov pa roj paug plasma, los ntawm lub luag hauj lwm ntawm hluav taws xob teb mus txog rau lub substrate los tsim nyias films; qhov tom kawg yog kev siv cov ions siab zog (xws li, Ar +) rau ntawm qhov chaw ntawm cov khoom siv zaj duab xis bombardment kom lub sputtering tawm ntawm cov hais los ntawm qhov chaw ntawm cov pa tawm ionized rau hauv ions los yog high-zog neutral atoms, mus txog rau saum npoo ntawm substrate thiab tsim cov zaj duab xis.

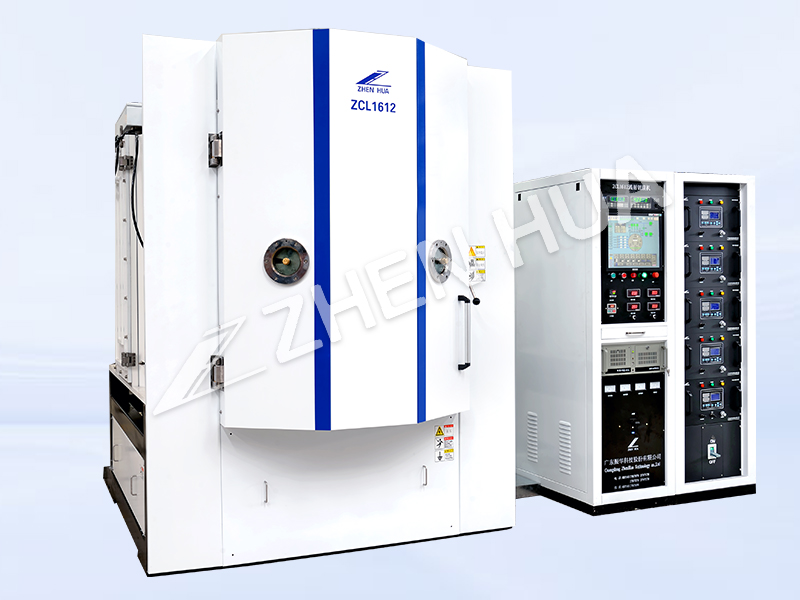

– Zaj lus no yog tso tawm los ntawmtshuab nqus tsev txheej tshuab manufacturersGuangdong Zhenhua

Post lub sij hawm: Mar-07-2024