1. Features of daahan sputter

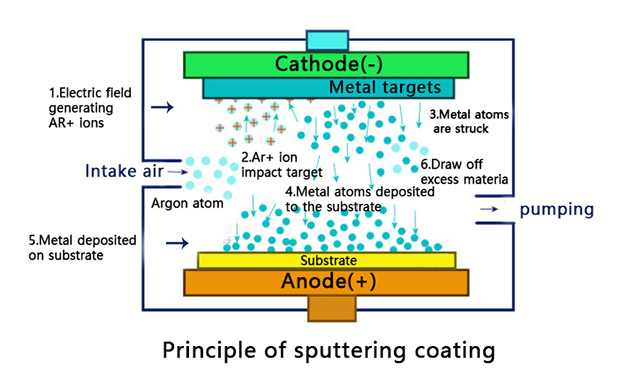

Marka la barbar dhigo daahan uumiga faakuumka caadiga ah, dahaarka sputtering wuxuu leeyahay sifooyinka soo socda:

(1) Walax kasta waa la daadin karaa, gaar ahaan barta dhalaalka sare, walxaha cadaadiska uumiga hooseeya iyo xeryahooda.Ilaa iyo inta ay tahay mid adag, haddii ay tahay bir, semiconductor, insulator, xayndaab iyo isku dar ah, iwm, haddii ay tahay block, walxaha granular waxaa loo isticmaali karaa walxo bartilmaameed ah.Maaddaama burburka yar iyo jajabku ay dhacaan marka la daadiyo walxaha dahaarka ah iyo alloys sida oksaydhyada, waxaa loo isticmaali karaa in lagu diyaariyo filimada khafiifka ah iyo aflaanta aluminiumka ah ee leh qaybo isku mid ah oo la mid ah kuwa la beegsanayo, iyo xitaa filimaan heer sare ah oo leh halabuur adag. Habka sputtering reactive waxa kale oo loo isticmaali karaa in lagu soo saaro filimada xeryahooda si buuxda uga duwan walxaha bartilmaameedka, sida oxides, nitrides, carbides iyo silicides.

(2) Ku-dhejin wanaagsan oo u dhexeeya filimka la daadiyay iyo substrate-ka.Maadaama tamarta atamka la daadiyey ay 1-2 amar ka sarreyso kan atamka la uumibixiyey, beddelka tamarta ee walxaha tamarta sare leh ee lagu shubo substrate-ka ayaa abuura tamar heerkul sare ah, taas oo kor u qaadeysa ku-xidhka atamka la daadiyey ee substrate-ka.Qayb ka mid ah atamka tamarta sare leh ayaa lagu duri doonaa heerar kala duwan, samaynta waxa loogu yeero lakabka faafinta been abuurka ah ee substrate halkaas oo atamka miiray iyo atamka maaddada substrate-ka ay isku “miscible” midba midka kale.Intaa waxaa dheer, inta lagu guda jiro duqeynta qaybaha sputtering, substrate had iyo jeer waa la nadiifiyaa oo la hawlgeliyay aagga plasma, kaas oo ka saaraya atomyada degdega ah ee liidata, nadiifinta iyo dhaqaajinta dusha sare ee substrate.Natiijo ahaan, adhesion ee lakabka filimka suufka ah ee substrate si weyn ayaa loo wanaajiyey.

(3) Cufnaanta sare ee dahaarka sputter-ka, godad yar yar, iyo nadiifinta sare ee lakabka filimka sababtoo ah ma jirto wasakhayn qallafsan, taas oo aan laga maarmi karin kaydinta uumiga faakuumka inta lagu jiro habka daahitaanka sputter.

(4) Xakamaynta wanaagsan iyo ku celcelinta dhumucda filimka.Maaddaama qulqulka hadda jira iyo bartilmaameedka hadda si gaar ah loo xakameyn karo inta lagu jiro daahan sputter, dhumucda filimka waxaa lagu xakameyn karaa iyada oo la xakameynayo bartilmaameedka hadda, sidaas darteed, xakamaynta dhumucda filimka iyo dib-u-soo-saarka dhumucda filimka iyadoo la adeegsanayo kala-baxyo badan oo daahan sputter ah ayaa wanaagsan. , iyo filimka dhumucda hore loo go'aamiyay ayaa si wax ku ool ah loo dabooli karaa.Intaa waxaa dheer, dahaarka sputter wuxuu heli karaa dhumucdiis filim isku mid ah oo ka badan aag ballaaran.Si kastaba ha ahaatee, tignoolajiyada dahaarka guud ee sputter-ka (badanaa xajinta dipole), qalabku waa adag yahay wuxuuna u baahan yahay qalab cadaadis sare leh;Xawaaraha samaynta filimka ee dhigista xajinta ayaa hooseysa, heerka uumiga uumiga waa 0.1 ~ 5nm / min, halka heerka xajinta uu yahay 0.01 ~ 0.5nm / min;Si kastaba ha ahaatee, sababtoo ah horumarinta RF sputtering iyo tignoolajiyada magnetron sputtering, horumar weyn ayaa la gaaray si loo gaaro meel deg deg ah sputtering iyo yaraynta heerkulka substrate ah.Waxaa intaa dheer, sannadihii ugu dambeeyay, hababka daahan cusub ee daahan ayaa la baarayaa - oo ku salaysan qorshaha magnetron sputtering - si loo yareeyo cadaadiska hawada ee xajinta ilaa eber-cadaadiska halkaasoo cadaadiska gaaska qaadashada inta lagu jiro sputtering uu noqon doono eber.

Waqtiga boostada: Nov-08-2022