1, Nta ntawm sputter txheej

Piv nrog cov pa nqus evaporation txheej, sputtering txheej muaj cov nram qab no nta:

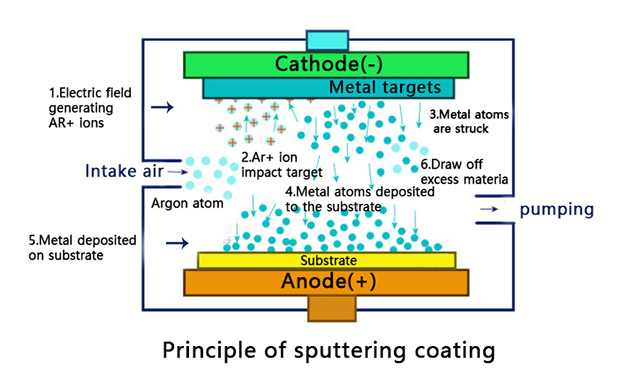

(1) Txhua yam khoom tuaj yeem raug sputtered, tshwj xeeb tshaj yog kub melting point, tsis tshua muaj vapor siab cov ntsiab lus thiab cov tebchaw.Tsuav nws yog cov khoom, txawm tias nws yog hlau, semiconductor, insulator, compound thiab sib tov, thiab lwm yam, txawm tias nws yog ib qho thaiv, cov khoom siv granular tuaj yeem siv los ua cov khoom siv.Txij li thaum me me decomposition thiab fractionation tshwm sim thaum sputtering insulating cov ntaub ntawv thiab alloys xws li oxides, lawv yuav siv tau los npaj nyias films thiab alloy films nrog uniform Cheebtsam zoo ib yam li cov hom phiaj cov khoom, thiab txawm superconducting films nrog complex compositions.' Ntxiv rau, cov txheej txheem reactive sputtering kuj tseem siv tau los tsim cov yeeb yaj kiab ntawm cov khoom sib txuas sib txawv ntawm cov khoom siv, xws li oxides, nitrides, carbides thiab silicides.

(2) Zoo adhesion ntawm sputtered zaj duab xis thiab substrate.Txij li thaum lub zog ntawm sputtered atoms yog 1-2 qhov kev txiav txim siab ntau dua li ntawm evaporated atoms, lub zog hloov pauv ntawm cov khoom siv hluav taws xob siab tso rau ntawm lub substrate generates thermal zog ntau dua, uas txhim kho cov adhesion ntawm sputtered atoms rau lub substrate.Ib feem ntawm lub zog siab sputtered atoms yuav raug txhaj rau ntau qhov sib txawv, tsim cov txheej txheej hu ua pseudo-diffusion ntawm cov substrate uas cov atoms sputtered thiab cov atoms ntawm cov khoom siv substrate "miscible" nrog ib leeg.Tsis tas li ntawd, thaum lub sij hawm foob pob hluav taws ntawm sputtering hais, lub substrate yeej ib txwm ntxuav thiab qhib rau hauv plasma cheeb tsam, uas tshem tawm cov tsis zoo adhered precipitated atoms, purifies thiab activates lub substrate nto.Yog li ntawd, lub adhesion ntawm sputtered zaj duab xis txheej rau lub substrate yog heev txhim khu kev qha.

(3) High density ntawm sputter txheej, tsawg pinholes, thiab siab dua purity ntawm cov zaj duab xis txheej vim hais tias tsis muaj crucible contamination, uas yog unavoidable nyob rau hauv lub tshuab nqus tsev vapor deposition thaum lub sij hawm sputter txheej txheej txheem.

(4) Zoo controllability thiab repeatability ntawm zaj duab xis thickness.Txij li cov paug tawm tam sim no thiab lub hom phiaj tam sim no tuaj yeem tswj tau nyias thaum lub sijhawm txheej txheej txheej, zaj duab xis tuab tuaj yeem tswj tau los ntawm kev tswj lub hom phiaj tam sim no, yog li, kev tswj hwm ntawm zaj duab xis thickness thiab rov tsim dua ntawm zaj duab xis thickness los ntawm ntau yam sputtering ntawm sputter txheej yog zoo. , thiab zaj duab xis ntawm predetermined thickness tuaj yeem coated zoo.Tsis tas li ntawd, sputter txheej tuaj yeem tau txais cov yeeb yaj kiab tsis sib xws ntawm thaj tsam loj.Txawm li cas los xij, rau cov txheej txheem txheej txheem dav dav (feem ntau yog dipole sputtering), cov cuab yeej nyuaj thiab yuav tsum muaj cov cuab yeej siv siab;Cov zaj duab xis tsim ceev ntawm sputter deposition yog tsawg, lub tshuab nqus tsev vaporation deposition tus nqi yog 0.1 ~ 5nm / min, thaum lub sputtering tus nqi yog 0.01 ~ 0.5nm / min;Lub substrate kub nce siab thiab yooj yim rau impurity gas, thiab lwm yam, Txawm li cas los xij, vim yog kev txhim kho ntawm RF sputtering thiab magnetron sputtering technology, kev vam meej tau txais txiaj ntsig zoo hauv kev ua kom tau raws li qhov ceev ceev sputtering deposition thiab txo cov substrate kub.Tsis tas li ntawd, nyob rau hauv xyoo tas los no, cov txheej txheem tshiab sputter txheej tau raug tshawb xyuas - raws li cov phiaj xwm magnetron sputtering - kom txo qis cov cua tshuab cua kom txog thaum xoom-pressure sputtering qhov twg lub siab ntawm cov pa roj thaum lub sij hawm sputtering yuav xoom.

Post lub sij hawm: Nov-08-2022