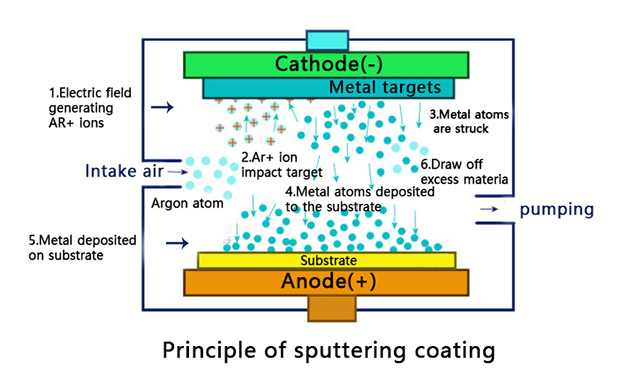

1. Atụmatụ nke sputter mkpuchi

N'iji ya na mkpuchi ikuku evaporation nkịtị, mkpuchi sputtering nwere atụmatụ ndị a:

(1) Enwere ike ịgbasa ihe ọ bụla, ọkachasị ebe mgbaze dị elu, ihe nrụgide ikuku dị ala na ogige. Ọ bụrụhaala na ọ bụ ihe siri ike, ma ọ bụ ígwè, semiconductor, insulator, compound na ngwakọta, wdg, ma ọ bụ ngọngọ, a pụrụ iji ihe granular mee ihe dị ka ihe mgbaru ọsọ. Ebe ọ bụ na obere ire ere na fractionation na-eme mgbe a na-agbasa ihe mkpuchi mkpuchi na alloys dị ka oxides, ha nwere ike iji kwadebe ihe nkiri dị mkpa na ihe nkiri alloy nwere ihe ndị yiri nke ihe a na-achọsi ike, na ọbụna ihe nkiri na-emepụta ihe na ihe mgbagwoju anya.' Tụkwasị na nke ahụ, a pụkwara iji usoro reactive sputtering na-emepụta ihe nkiri nke ogige dị iche iche dị ka oxides sitrides, dị ka oxides sitrides.

(2) Ezigbo mmachi n'etiti ihe nkiri sputtered na mkpụrụ. Ebe ọ bụ na ike nke atọm sputtered bụ 1-2 iwu nke ịdị ukwuu karịa nke evaporated atọm, ike ntughari nke elu-ike ụmụ irighiri etinye na substrate na-emepụta elu thermal ike, nke na-eme ka adhesion nke sputtered atọm na mkpụrụ. A ga-agbanye akụkụ nke atom ndị nwere ume dị elu na ogo dị iche iche, na-akpụ ihe a na-akpọ pseudo-diffusion oyi akwa n'elu mkpụrụ ebe atom ndị na-agbapụta na atom nke ihe ndị na-emepụta ihe na-eme ka ha na-ejikọta ibe ha. Na mgbakwunye, n'oge ogbunigwe nke ụmụ irighiri ihe na-agbapụta, a na-ehicha ma na-arụ ọrụ na mpaghara plasma mgbe niile, nke na-ewepụ atom ndị a na-ejighị n'aka, na-asachapụ ma na-arụ ọrụ n'elu ala. N'ihi ya, adhesion nke oyi akwa ihe nkiri na-efesa na-emewanyewanye nke ọma.

(3) Nnukwu njupụta nke mkpuchi sputter, obere pinholes, na ịdị ọcha dị elu nke oyi akwa ihe nkiri ahụ n'ihi na ọ dịghị ihe na-emerụ emerụ, bụ nke a na-apụghị izere ezere na ntinye oghere ikuku n'oge usoro mkpuchi sputter.

(4) Ezi njikwa na repeatability nke ihe nkiri ọkpụrụkpụ. Ebe ọ bụ na ihapu ugbu a na lekwasịrị anya ugbu a nwere ike ịchịkwa iche iche n'oge sputter mkpuchi, ihe nkiri ọkpụrụkpụ nwere ike ịchịkwa site na ịchịkwa lekwasịrị ugbu a, otú, na controllability nke film ọkpụrụkpụ na reproducibility nke film ọkpụrụkpụ site multiple sputtering nke sputter mkpuchi dị mma, na ihe nkiri nke predetermined ọkpụrụkpụ nwere ike nke ọma ntekwasa. Na mgbakwunye, mkpuchi sputter nwere ike nweta ọkpụrụkpụ ihe nkiri edo edo karịa ebe buru ibu. Otú ọ dị, maka nkà na ụzụ mkpuchi sputter n'ozuzu (karịsịa dipole sputtering), ngwá ọrụ dị mgbagwoju anya ma na-achọ ngwaọrụ nrụgide dị elu; The film guzobe ọsọ nke sputter ntinye bụ ala, agụụ evaporation ntinye ọnụego bụ 0.1 ~ 5nm / min, mgbe sputtering ọnụego bụ 0.01 ~ 0.5nm / min; ịrị elu nke mkpụrụ osisi dị elu ma nwee ike ịnweta gas na-adịghị ọcha, wdg. Otú ọ dị, n'ihi mmepe nke RF sputtering na magnetron sputtering technology, a na-enweta ọganihu dị ukwuu n'inweta ntinye ngwa ngwa na ibelata okpomọkụ nke mkpụrụ. Ọzọkwa, n'ime afọ ndị na-adịbeghị anya, a na-enyocha ụzọ mkpuchi sputter ọhụrụ - dabere na atụmatụ magnetron sputtering - iji belata ikuku ikuku na-agbapụta ruo mgbe ikuku na-enweghị ike ịgbasa ebe nrụgide nke gas oriri n'oge sputtering ga-abụ efu.

Oge nzipu: Nov-08-2022