Chinhu chikuru chevacuum evaporation nzira yekuisa mafirimu ndiyo yakanyanya deposition rate.Chinhu chikuru cheiyo sputtering nzira ndeye kuwanda kwezvinhu zviripo zvemufirimu uye kuwirirana kwakanaka kweiyo firimu layer, asi deposition rate yakaderera.Ion coating inzira inosanganisa maitiro maviri aya.

Ion coating musimboti uye firimu kuumbwa mamiriro

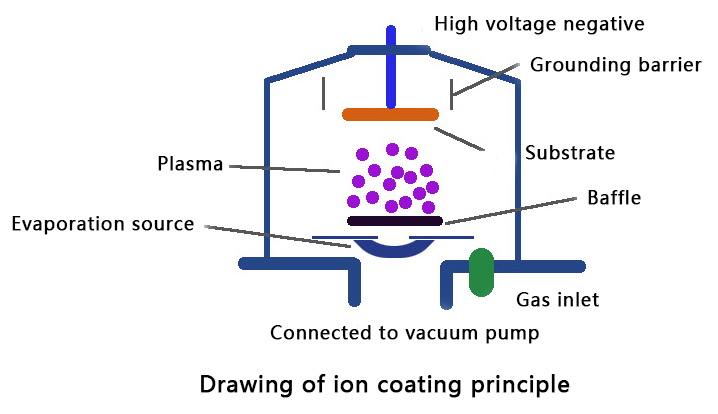

Iyo yekushanda nheyo yeion coating inoratidzwa muPic.Imba yevacuum inoputirwa kumhepo iri pasi pe 10-4 Pa, uye yobva yazadzwa neinert gas (eg argon) kune kumanikidzwa kwe 0.1 ~ 1 Pa. Mushure mekushaya DC voltage kusvika ku5 kV inoshandiswa kune substrate, a. low pressure gasi glow discharge plasma zone inogadzwa pakati pe substrate necrucible.Iyo inert gasi ions inokurumidzirwa nemunda wemagetsi uye bhomba pamusoro pe substrate, nokudaro kuchenesa pamusoro pebasa rekushanda.Mushure mekuita uku kwekuchenesa kwapera, maitiro ekuputira anotanga nekunyungudika kwezvinhu kuti zviputirwe mucrucible.Iyo vaporized vapor particles inopinda munzvimbo yeplasma uye inodhumhana neiyo dissociated inert positive ions uye maerekitironi, uye mamwe emhute particles anoparadzaniswa uye anobhomba workpiece uye yekuputira pamusoro pasi pekumhanyisa kwemunda wemagetsi.Muiyo ion plating process, hapangori nekuisa chete asiwo nekupopotera kweiyoni yakanaka pane substrate, saka iyo firimu yakatetepa inogona kuumbwa chete kana deposition mhedzisiro yakakura kupfuura sputtering athari.

Iyo ion coating process, umo iyo substrate inogara yakabhomba neakakwira-energy ions, yakachena kwazvo uye ine huwandu hwezvakanakira zvichienzaniswa nekuputira uye evaporation coating.

(1) Yakasimba yekunamatira, yekubikira layer haibvire nyore.

(a) Mukuita ion coating process, huwandu hukuru hwehukuru-simba zvimedu zvinogadzirwa nekupenya kwekubuda zvinoshandiswa kugadzira cathodic sputtering athari pamusoro peiyo substrate, kupuruzira uye kuchenesa gasi nemafuta adsorbed pamusoro peiyo. substrate yekuchenesa iyo substrate pamusoro kusvikira iyo yose yekupfekedza maitiro yapera.

(b)Pakutanga nhanho yekupfekedza, kupuruzira uye kuisa pamwe chete, izvo zvinogona kuita shanduko yezvikamu pachikamu chebhaisikopo kana musanganiswa wezvinhu zvemufirimu uye zvinhu zvepasi, zvinonzi "pseudo-diffusion layer", iyo inogona kunyatso kuvandudza kushanda kwekunamatira kwefirimu.

(2)Zvinhu zvakanaka zvekuputira.Chimwe chikonzero ndechekuti maatomu ekuputira anoiswa ionized pasi pekumanikidzwa kwakanyanya uye anodhumhana nemamorekuru egasi kakawanda panguva yekusvika kune substrate, kuitira kuti maion emidziyo yekuputira ipararire kutenderedza substrate.Pamusoro pezvo, maatomu ekuputira ionized akaiswa pamusoro peiyo substrate pasi pechiito chemagetsi, saka iyo substrate yese inoiswa nefirimu rakatetepa, asi evaporation coating haigone kuita izvi.

(3) Hunhu hwepamusoro hwehuputi hunokonzerwa nekuputirwa kwema condensates kunokonzerwa nebhomba rinogara riripo refirimu rakaiswa neonisi yakanaka, iyo inovandudza kuwanda kwechifukidzo chekuvhara.

(4) Sarudzo yakawanda yekupfekedza zvinhu uye substrates inogona kuputirwa pane esimbi kana isiri-simbi zvinhu.

(5) Kana ichienzaniswa nemakemikari vapor deposition (CVD), ine yakadzika substrate tembiricha, kazhinji iri pasi pe500 ° C, asi simba rayo rekunamatira rinofananidzwa zvizere nemakemikari vapor deposition mafirimu.

(6) Yakakwira deposition rate, inokurumidza kuumbwa kwefirimu, uye yaigona kupfekedza ukobvu hwemafirimu kubva kumakumi ema nanometers kusvika mamicrons.

Izvo zvisingabatsiri zvekuputira ion ndezvi: kuwanda kwefirimu hakugoni kunyatsodzorwa;kuwanda kwekuremara kwakakwirira kana kupfeka kwakanaka kunodiwa;uye magasi achapinda pamusoro panguva yekuputira, izvo zvinoshandura nzvimbo dzepamusoro.Mune zvimwe zviitiko, cavities uye nuclei (pasi pe1 nm) inoumbwawo.

Kana iri deposition rate, ion coating inofananidzwa neiyo evaporation nzira.Kana ari emhando yefirimu, mafirimu anogadzirwa neion coating ari padyo kana nani pane ayo akagadzirirwa nekupopota.

Nguva yekutumira: Nov-08-2022