Chofunikira chachikulu cha njira ya vacuum evaporation poyika mafilimu ndi kuchuluka kwa ma deposition.Chofunikira chachikulu cha njira ya sputtering ndi mitundu yambiri ya filimu yomwe ilipo komanso kufanana kwabwino kwa filimuyi, koma chiwerengero cha kuika ndi chochepa.Kupaka ion ndi njira yomwe imaphatikiza njira ziwirizi.

Ion ❖ kuyanika mfundo ndi filimu mapangidwe zinthu

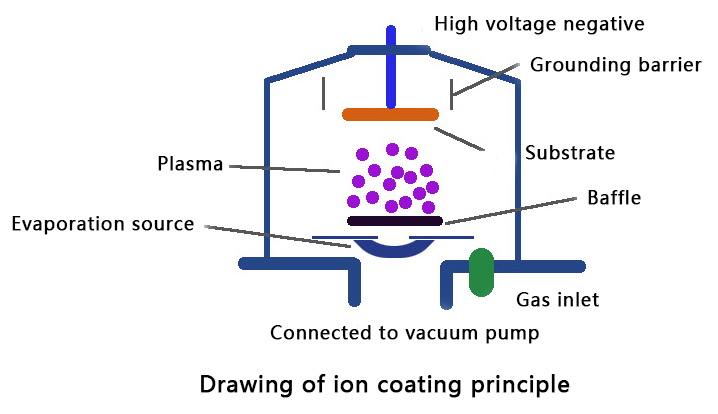

Mfundo yogwiritsira ntchito zokutira ion ikuwonetsedwa mu Pic.Chipinda cha vacuum chimapopedwa kuti chikhale pansi pa 10-4 Pa, ndiyeno chimadzazidwa ndi mpweya wa inert (mwachitsanzo, argon) mpaka kupanikizika kwa 0.1 ~ 1 Pa. Pambuyo pamagetsi olakwika a DC mpaka 5 kV amagwiritsidwa ntchito ku gawo lapansi, a. kutsika kwamphamvu kwa mpweya wotulutsa mpweya wa plasma kumakhazikitsidwa pakati pa gawo lapansi ndi crucible.Ma ion a gasi a inert amafulumizitsidwa ndi gawo lamagetsi ndikuwombera pamwamba pa gawo lapansi, motero amayeretsa pamwamba pa ntchitoyo.Ntchito yoyeretsayi ikamalizidwa, kuphimba kumayamba ndi vaporization yazinthu zomwe zimakutidwa mu crucible.The vaporized nthunzi particles kulowa plasma zone ndi kugunda ndi dissociated inert zabwino ayoni ndi ma elekitironi, ndi ena mwa nthunzi particles ndi dissociated ndi bombard workpiece ndi ❖ kuyanika pamwamba pansi pa mathamangitsidwe a kumunda magetsi.Pakuyika kwa ion plating, sikumangokhalira kuyika komanso kutulutsa ma ion abwino pagawo lapansi, kotero kuti filimu yopyapyala imatha kupangidwa pokhapokha ngati zotsatira zake zimakhala zazikulu kuposa kutulutsa.

Njira yokutira ya ion, yomwe gawo lapansili nthawi zonse limakhala ndi ma ion amphamvu kwambiri, amakhala oyera kwambiri ndipo ali ndi maubwino angapo poyerekeza ndi kupaka utoto ndi evaporation.

(1)Kumamatira mwamphamvu, nsanjika yophimba sivunda mosavuta.

(a) Mu ❖ kuyanika kwa ion, tinthu tambiri tambiri tambiri timene timapangidwa ndi kutulutsa kowala kumagwiritsidwa ntchito kutulutsa mphamvu ya cathodic sputtering pamwamba pa gawo lapansi, kupaka ndi kuyeretsa gasi ndi mafuta omwe amatsuka pamwamba pa nthaka. gawo lapansi kuyeretsa gawo lapansi mpaka ntchito yonse yokutira itatha.

(b) Kumayambiriro kwa zokutira, sputtering ndi deposition zimakhala pamodzi, zomwe zingapangitse kusintha kwa zigawo pa mawonekedwe a filimuyo kapena kusakaniza filimuyo ndi zinthu zoyambira, zomwe zimatchedwa "pseudo-diffusion layer", zomwe zimatha kupititsa patsogolo luso lomatira la filimuyo.

(2) Zinthu zabwino zokulunga.Chifukwa chimodzi ndi chakuti maatomu ❖ kuyanika zakuthupi ndi ionized pansi pa kuthamanga kwambiri ndi kugunda ndi mamolekyu mpweya kangapo pa ndondomeko kufika gawo lapansi, kuti ❖ kuyanika zinthu ayoni akhoza kumwazikana mozungulira gawo lapansi.Kuonjezera apo, maatomu opaka ionized amayikidwa pamwamba pa gawo lapansi pansi pa mphamvu ya magetsi, kotero gawo lapansi lonse limayikidwa ndi filimu yopyapyala, koma kuyanika kwa evaporation sikungathe kukwaniritsa izi.

(3) Ubwino wa zokutira ndi chifukwa cha sputtering wa condensates chifukwa cha bombardment mosalekeza wa filimu waikamo ndi ayoni zabwino, amene bwino kachulukidwe wa ❖ kuyanika wosanjikiza.

(4) Kusankhidwa kwakukulu kwa zida zokutira ndi magawo angatilidwe pazitsulo zazitsulo kapena zopanda zitsulo.

(5) Poyerekeza ndi chemical vapor deposition (CVD), imakhala ndi kutentha kwapansi pansi, komwe kumakhala pansi pa 500 ° C, koma mphamvu yake yomatira imafanana kwambiri ndi mafilimu opangira mpweya wa mankhwala.

+

Zoyipa za zokutira za ion ndizo: makulidwe a filimu sangathe kuyendetsedwa bwino;kuchuluka kwa zolakwika kumakhala kwakukulu pamene zokutira zabwino zimafunika;ndipo mipweya idzalowa pamwamba pa zokutira, zomwe zidzasintha mawonekedwe apamwamba.Nthawi zina, ma cavities ndi ma nuclei (osakwana 1 nm) amapangidwanso.

Ponena za kuchuluka kwa kuyika, zokutira za ion zikufanana ndi njira ya evaporation.Ponena za khalidwe la mafilimu, mafilimu opangidwa ndi zokutira ion ali pafupi kapena abwino kuposa omwe amakonzedwa ndi sputtering.

Nthawi yotumiza: Nov-08-2022