Txoj cai ntawm lub tshuab nqus tsev evaporation txheej

1, Khoom siv thiab lub cev txheej txheem ntawm lub tshuab nqus tsev evaporation txheej

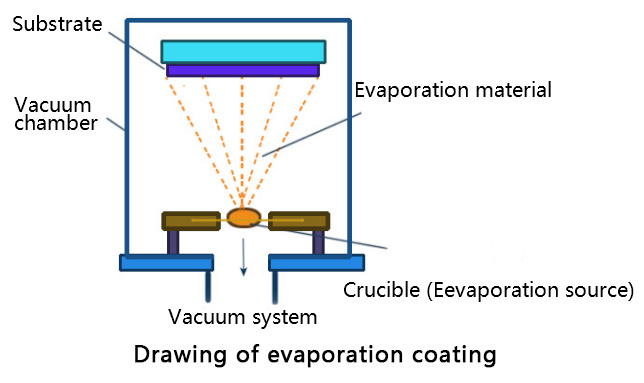

Lub tshuab nqus tsev evaporation txheej cov cuab yeej yog tsim los ntawm lub tshuab nqus tsev vacuum thiab kev khiav tawm.Nyob rau hauv lub tshuab nqus tsev chamber, muaj evaporation qhov chaw (xws li evaporation rhaub), substrate thiab substrate ncej, substrate heater, tso system, thiab lwm yam.

Cov khoom siv txheej yog muab tso rau hauv qhov chaw evaporation ntawm lub tshuab nqus tsev chamber, thiab nyob rau hauv lub tshuab nqus tsev siab, nws yog rhuab los ntawm qhov chaw evaporation kom evaporate.Thaum qhov nruab nrab pub dawb ntawm cov vapor molecules loj dua li qhov loj me ntawm lub tshuab nqus tsev, tom qab cov atoms thiab molecules ntawm cov yeeb yaj kiab vapor khiav tawm ntawm qhov chaw evaporation, tsis tshua muaj kev cuam tshuam los ntawm kev sib tsoo ntawm lwm cov molecules lossis atoms, thiab ncaj qha mus txog saum npoo ntawm substrate yuav tsum tau coated.Vim qhov kub ntawm cov substrate qis, cov yeeb yaj kiab vapor hais condense rau nws thiab tsim ib zaj duab xis.

Txhawm rau txhim kho qhov adhesion ntawm evaporation molecules thiab substrate, lub substrate tuaj yeem qhib tau los ntawm kev siv cua sov los yog ion tu.Lub tshuab nqus tsev evaporation txheej dhau los ntawm cov txheej txheem hauv qab no los ntawm cov khoom evaporation, kev thauj mus los rau kev tso rau hauv zaj duab xis.

(1) Siv ntau txoj hauv kev los hloov lwm yam ntawm lub zog rau hauv lub zog thermal, cov khoom siv zaj duab xis yog rhuab kom evaporate lossis sublimate rau hauv cov pa roj (atoms, molecules lossis atomic pawg) nrog rau qee lub zog (0.1 txog 0.3 eV).

(2) Gaseous hais tawm ntawm qhov chaw ntawm zaj duab xis thiab raug thauj mus rau saum npoo ntawm substrate ntawm ib qho kev ceev ntawm kev txav, qhov tseem ceeb yam tsis muaj kev sib tsoo, hauv txoj kab ncaj nraim.

(3) Lub gaseous hais txog qhov chaw ntawm lub substrate coalesce thiab nucleate, thiab ces loj hlob mus rau hauv ib tug solid-theem zaj duab xis.

(4) Reorganization lossis tshuaj sib txuas ntawm cov atoms uas ua rau cov yeeb yaj kiab.

2, Evaporation cua sov

(1) Resistance cua sov evaporation

Resistance cua sov evaporation yog qhov yooj yim tshaj plaws thiab feem ntau siv cua sov txoj kev, feem ntau yog siv rau txheej cov ntaub ntawv nrog melting point hauv qab 1500 ℃, siab melting point hlau nyob rau hauv hlau los yog daim ntawv zoo li (W, Mo, Ti, Ta, boron nitride, thiab lwm yam) yog. Feem ntau ua rau hauv cov khoom tsim nyog ntawm evaporation qhov chaw, ntim nrog cov ntaub ntawv evaporation, los ntawm Joule tshav kub ntawm cov hluav taws xob tam sim no kom yaj, evaporate lossis sublimate cov khoom siv plating, cov duab ntawm evaporation qhov chaw feem ntau suav nrog ntau txoj hlua khi, U-shaped, sine yoj. , nyias phaj, nkoj, pob tawb pob tawb, thiab lwm yam tib lub sijhawm, txoj kev xav tau cov khoom siv evaporation kom muaj cov ntsiab lus siab melting, tsis tshua muaj saturation vapor siab, ruaj khov khoom, tsis muaj tshuaj lom neeg cov tshuaj tiv thaiv nrog cov txheej txheem ntawm qhov kub thiab txias, Cov cua sov zoo, kev hloov pauv me me ntawm lub zog ntom ntom, thiab lwm yam. Nws siv lub zog tam sim no los ntawm qhov chaw evaporation los ua kom nws sov thiab evaporate cov ntaub ntawv zaj duab xis los ntawm cua sov ncaj qha, lossis muab cov khoom siv zaj duab xis tso rau hauv lub crucible ua los ntawm graphite thiab tej yam kub resistant. hlau oxides (xws li A202, B0) thiab lwm yam ntaub ntawv rau indirect cua sov kom evaporate.

Resistance cua sov evaporation txheej muaj kev txwv: cov hlau refractory muaj tsawg vapor siab, uas yog ib qho nyuaj ua rau nyias zaj duab xis;qee cov ntsiab lus yog ib qho yooj yim los ua ib qho alloy nrog cov cua sov hlau;nws tsis yooj yim kom tau txais ib qho kev sib xyaw ntawm cov yeeb yaj kiab alloy.Vim yog cov qauv yooj yim, tus nqi qis thiab kev ua haujlwm yooj yim ntawm kev tiv thaiv cua sov evaporation, nws yog ib qho kev siv ntau heev ntawm evaporation txoj kev.

(2) Electron beam cua sov evaporation

Electron beam evaporation yog ib txoj hauv kev ntawm evaporating cov khoom txheej los ntawm kev sib tsoo nws nrog lub zog hluav taws xob siab ceev hluav taws xob los ntawm kev muab tso rau hauv dej-txias tooj liab crucible.Lub evaporation qhov chaw muaj xws li ib tug electron emission qhov chaw, ib tug electron acceleration zog qhov chaw, ib tug crucible (feem ntau yog ib tug tooj liab crucible), ib tug magnetic teb coil, thiab ib tug txias dej teeb, thiab lwm yam. Nyob rau hauv lub ntaus ntawv no, cov khoom rhuab yog muab tso rau hauv ib tug dej. -cooled crucible, thiab electron beam bombards tsuas yog ib feem me me ntawm cov khoom, thaum feem ntau ntawm cov khoom seem tseem nyob rau ntawm qhov kub thiab txias heev nyob rau hauv lub txias nyhuv ntawm crucible, uas yuav suav tau tias yog ib feem ntawm lub crucible.Yog li, txoj kev siv hluav taws xob hluav taws xob cua sov rau evaporation tuaj yeem zam kev sib kis ntawm cov khoom siv txheej thiab cov khoom siv evaporation.

Cov qauv ntawm cov kab hluav taws xob hluav taws xob evaporation tuaj yeem muab faib ua peb hom: phom ncaj (Boules phom), phom nplhaib (hluav taws xob deflected) thiab e-phom (magnetically deflected).Ib lossis ntau lub crucibles tuaj yeem muab tso rau hauv qhov chaw evaporation, uas tuaj yeem evaporate thiab tso ntau yam khoom sib txawv ib txhij lossis sib cais.

Electron beam evaporation qhov chaw muaj qhov zoo hauv qab no.

SHERTHE HIGHAL SPENSITY NTAWM COV Electron Daus Bombardments Evaporation Qhov Chaw Muaj Peev Xwm Ntau Dua Li Cov Khoom Siv Hluav Taws Xob, Uas Muaj W, Mo, Al2o3, Thiab Lwm Yam ..

② Cov khoom siv txheej yog muab tso rau hauv cov dej-txias tooj liab crucible, uas tuaj yeem zam qhov evaporation ntawm cov khoom siv evaporation, thiab cov tshuaj tiv thaiv ntawm lawv.

③ Thaum tshav kub kub tuaj yeem raug ntxiv ncaj qha rau saum npoo ntawm cov khoom siv txheej, uas ua rau thermal efficiency siab thiab poob ntawm cov hluav taws xob hluav taws xob thiab hluav taws xob hluav taws xob tsawg.

Qhov tsis zoo ntawm cov hluav taws xob hluav taws xob hluav taws xob cua sov evaporation txoj kev yog thawj cov khoom siv hluav taws xob los ntawm cov phom hluav taws xob thiab cov hluav taws xob thib ob los ntawm cov khoom siv txheej txheej yuav ionize cov evaporating atoms thiab cov roj seem molecules, uas yuav cuam tshuam rau qhov zoo ntawm cov yeeb yaj kiab qee zaum.

(3) High zaus induction cua sov evaporation

High-frequency induction cua sov evaporation yog tso lub crucible nrog cov ntaub ntawv txheej nyob rau hauv nruab nrab ntawm lub high-frequency kauv kauj, kom cov txheej txheej generates muaj zog eddy tam sim no thiab hysteresis nyhuv nyob rau hauv lub induction ntawm high-frequency electromagnetic teb, uas ua rau cov txheej txheem. zaj duab xis txheej kom sov kom txog thaum nws vaporizes thiab evaporates.Lub evaporation qhov chaw feem ntau muaj cov dej-txias high-frequency coil thiab graphite lossis ceramic (magnesium oxide, aluminium oxide, boron oxide, thiab lwm yam) crucible.Cov khoom siv hluav taws xob ntau zaus siv ntau zaus ntawm kaum txhiab mus rau ntau pua txhiab Hz, lub zog tawm tswv yim yog ob peb mus rau ntau pua kilowatts, qhov me me ntawm cov khoom siv membrane, qhov ntau dua induction.Induction coil zaus feem ntau yog ua los ntawm dej-txias tooj liab raj.

Qhov tsis zoo ntawm high-frequency induction cua sov evaporation txoj kev yog tias nws tsis yooj yim rau kev nplua kho lub zog input, nws muaj qhov zoo hauv qab no.

① High evaporation tus nqi

② Qhov kub ntawm qhov chaw evaporation yog qhov sib xws thiab ruaj khov, yog li nws tsis yooj yim los tsim qhov tshwm sim ntawm txheej txheej tee dej txaws, thiab nws tseem tuaj yeem zam qhov tshwm sim ntawm pinholes ntawm cov yeeb yaj kiab tso.

③ Lub evaporation qhov chaw thauj khoom ib zaug, thiab qhov kub thiab txias yog qhov yooj yim thiab yooj yim los tswj.

Post lub sij hawm: Oct-28-2022