Inqubo ye-Plasma ye-polymerization eqondile

Inqubo ye-Plasma polymerization ilula uma kuqhathaniswa kokubili okokusebenza kwe-electrode polymerization yangaphakathi kanye nemishini yangaphandle ye-electrode polymerization, kodwa ukukhethwa kwepharamitha kubaluleke kakhulu ku-Plasma polymerization, ngoba imingcele inomthelela omkhulu ekwakhiweni nasekusebenzeni kwamafilimu e-polymer ngesikhathi se-Plasma polymerization.

Izinyathelo zokusebenza ze-polymerization ye-plasma eqondile zimi kanje:

(1) Ukuhlanza

I-vacuum yangemuva ye-polymerization ngaphansi kwezimo ze-vacuum kufanele iphonswe ku-1.3×10-1Pa. Ngokusabela kwe-polymerization okudinga izidingo ezikhethekile zokulawula okuqukethwe kwe-oxygen noma i-nitrogen, imfuneko ye-vacuum yangemuva iphakeme nakakhulu.

(2) Shaja i-monomer yokusabela noma igesi exubile yegesi yenethiwekhi ne-monomer

I-vacuum degree yi-13-130Pa. Nge-Plasma polymerization edinga umsebenzi, imodi yokulawula ukugeleza efanele kanye nezinga lokugeleza kufanele kukhethwe, ngokuvamile i-10.100mL/min. Ku-plasma, ama-molecule e-monomer enziwa i-ionized futhi ahlukaniswa ngokuqhunyiswa kwamabhomu kwezinhlayiya ezinamandla, okuholela ezinhlayiyeni ezisebenzayo njengama-ion kanye nezakhi zofuzo ezisebenzayo. Izinhlayiya ezisebenzayo ezicushwe yi-plasma zingangena kwi-Plasma polymerization esibonakalayo sesigaba segesi kanye nesigaba esiqinile. I-monomer ingumthombo wesandulela se-Plasma polymerization, futhi igesi yokusabela okokufaka kanye ne-monomer kuzoba nokuhlanzeka okuthile.

(3) Ukukhethwa kwamandla kagesi avusa amadlingozi

I-Plasma ingakhiqizwa kusetshenziswa imithombo yamandla ye-DC, high-frequency, RF, noma i-microwave ukuze inikeze indawo ye-plasma yokwenza i-polymerization. Ukukhethwa kokunikezwa kwamandla kunqunywa ngokusekelwe ezidingweni zesakhiwo nokusebenza kwe-polymer.

(4) Ukukhethwa kwemodi yokukhipha

Ngezidingo ze-polymer, i-Plasma polymerization ingakhetha izindlela ezimbili zokukhipha: ukukhipha okuqhubekayo noma ukukhishwa kwe-pulse.

(5) Ukukhethwa kwemingcele yokukhipha

Lapho kwenziwa i-Plasma polymerization, imingcele yokukhipha idinga ukucatshangelwa kusuka kumingcele ye-plasma, izakhiwo ze-polymer kanye nezidingo zesakhiwo. Ubukhulu bamandla asetshenzisiwe ngesikhathi se-polymerization kunqunywa umthamo wegumbi le-vacuum, usayizi we-electrode, izinga lokugeleza kwe-monomer kanye nesakhiwo, izinga le-polymerization, kanye nesakhiwo se-polymer nokusebenza. Isibonelo, uma ivolumu yegumbi lokusabela ingu-1L futhi i-RF Plasma polymerization yamukelwa, amandla okukhipha azoba kububanzi obungu-10~30W. Ngaphansi kwezimo ezinjalo, i-plasma ekhiqizwayo ingahlanganiswa ukuze yakhe ifilimu elincanyana ebusweni bomsebenzi. Izinga lokukhula kwefilimu ye-Plasma polymerization liyahlukahluka ngokuya ngokunikezwa kwamandla, uhlobo lwe-monomer nezinga lokugeleza, nezimo zenqubo. Ngokuvamile, izinga lokukhula lingu-100nm/min~1um/min.

(6) Isilinganiso sepharamitha ku-Plasma polymerization

Imingcele ye-plasma kanye nemingcele yenqubo okufanele ikalwe ku-Plasma polymerization ihlanganisa: i-voltage yokukhipha, i-discharge yamanje, imvamisa yokukhipha, izinga lokushisa le-Electron, ukuminyana, uhlobo lweqembu lokuphendula nokugxila, njll.

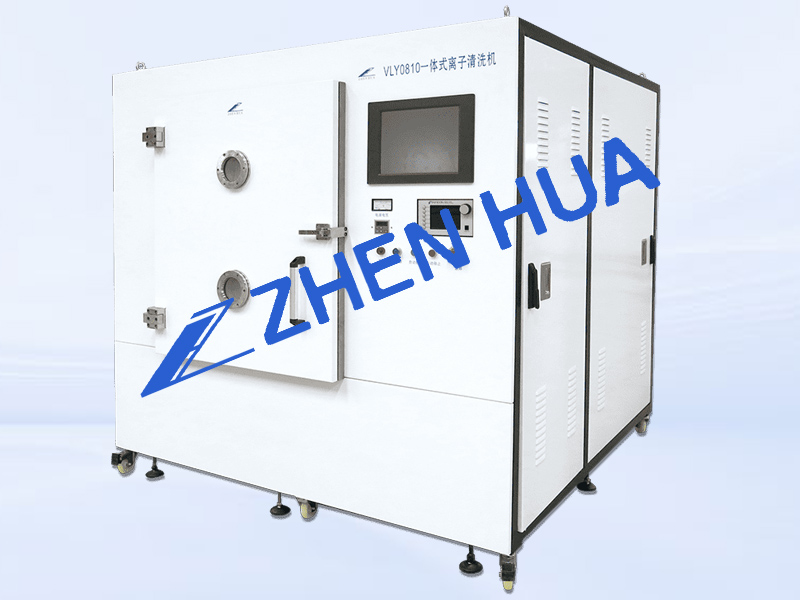

——Le ndatshana ikhishwe nguGuangdong Zhenhua Technology, aumkhiqizi wemishini yokuhlanganisa optical.

Isikhathi sokuthumela: May-05-2023