Mochini oa ho roala oa sputtering ho koahela mebala ea mookoli

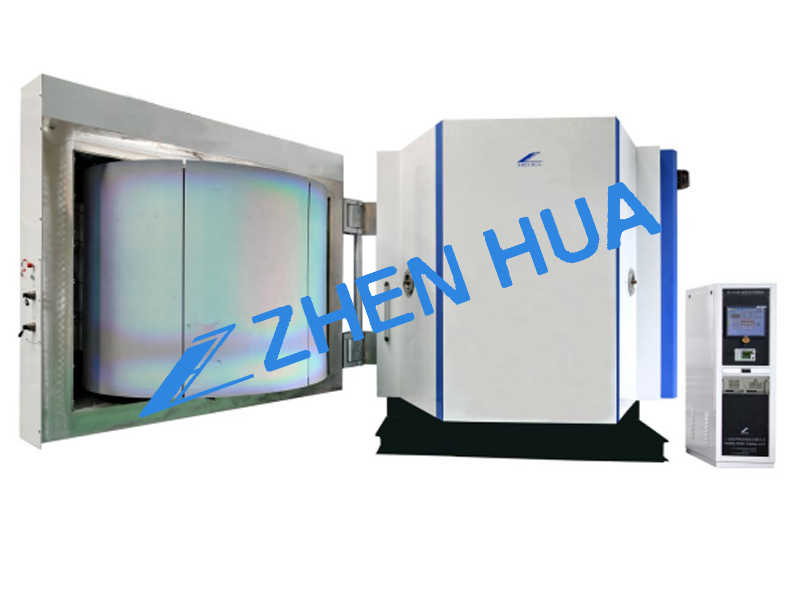

Magnetron sputtering ke mofuta oa mouoane oa 'mele. Mokhoa o tloaelehileng oa sputtering o ka sebelisoa ho roala tšepe, semiconductor, insulator le lisebelisoa tse ling, 'me o na le litšobotsi tse kholo tsa ho jara bokhoni , ho bonolo ho sebetsa, filimi ea ho roala e ntle haholo ebile e boreleli, e nang le ho khomarela hantle joalo-joalo. Magnetron sputtering e ka eketsa sekhahla sa ho fafatsa ka ho hlahisa matla a khoheli holim'a cathode ea sepheo le ho sebelisa thibelo ea matla a khoheli likarolong tse qosoang ho eketsa sekhahla sa plasma. Mochini o felletseng oa magnetron sputtering vacuum coating o entsoe ka likarolo tse ngata, sistimi e 'ngoe le e' ngoe e phethela mesebetsi e fapaneng, 'me qetellong e fihlelle boleng ba ho qetela ba boleng bo holimo. The magnetron sputtering optical barbotage thepa e entsoe ka vacuum kamoreng, phunyang, vacuum pumping sisteme, tsamaiso ea ho lekanya vacuum, cathode target, filimi botenya gauge, electro-pneumatic tsamaiso ea ho laola, joalo-joalo 'Mele o ka sehloohong oa magnetron sputtering optical coater ke vacuum kamoreng, boholo ba sehlahiswa le ho khethoa ha substrate boholo ba sehlahisoa. Kamore e entsoe ka tšepe e sa hloekang ea SUS304, e seng bonolo ho rusa, e tšoarella ho feta tšepe ea carbon le ho e hlokomela habonolo. Mochini o amohetse theknoloji ea ho roala maqhubu a mahareng, a koahela ka lisebelisoa tsa oxide tse kang silicon oxide le niobium oxide joalo-joalo, ka gauge ea botenya ba filimi ho etsa filimi e khabisitsoeng ea optical. Filimi e entsoeng ke magnetron sputtering optical coating machine e na le sekhomaretsi se matla le bohloeki bo phahameng, 'me se ka tšeloa ka lisebelisoa tse sa tšoaneng tse nang le likarolo tse fapaneng ka nako e le' ngoe.

Mokhoa oa ho fetola 'mala butle-butle hangata o etsoa ke mochini oa magnetron sputtering optical coating. Hajoale, sekoaelo se ka morao sa mehala e mengata ea cellular se nka PVD vacuum coating butle butle butle-butle. Ha e le hantle, mochine oa ho roala optical le mochini oa ho roala mouoane o ka boela oa etsa hore monokoli o ts'oane ka mebala e supileng, empa mebala ha e na li-gradients tse tloaelehileng 'me ho ntse ho e-na le phapang ea boleng. Magnetron sputtering ke mofuta oa mouoane oa 'mele. Mokhoa o tloaelehileng oa sputtering o ka sebelisoa ho roala tšepe, semiconductor, insulator le lisebelisoa tse ling, 'me o na le litšobotsi tse kholo tsa ho jara bokhoni , ho bonolo ho sebetsa, filimi ea ho roala e ntle haholo ebile e boreleli, e nang le ho khomarela hantle joalo-joalo.

Magnetron sputtering e ka eketsa sekhahla sa ho fafatsa ka ho hlahisa matla a khoheli holim'a cathode ea sepheo le ho sebelisa thibelo ea matla a khoheli likarolong tse qosoang ho eketsa sekhahla sa plasma. Mochini o felletseng oa magnetron sputtering vacuum coating o entsoe ka likarolo tse ngata, sistimi e 'ngoe le e' ngoe e phethela mesebetsi e fapaneng, 'me qetellong e fihlelle boleng ba ho qetela ba boleng bo holimo. Thepa ea magnetron sputtering optical coating e entsoe ka kamore ea vacuum, valve, vacuum pumping system, vacuum measurement system, cathode target, gauge ea botenya ba filimi, sistimi ea taolo ea electro-pneumatic, jj.

'Mele o ka sehloohong oa magnetron sputtering optical coater ke kamore ea vacuum, boholo bo khethoa ke boholo ba sehlahisoa sa sehlahisoa le bokhoni ba mosebelisi. Kamore e entsoe ka tšepe e sa hloekang ea SUS304, e seng bonolo ho rusa, e tšoarella ho feta tšepe ea carbon le ho e hlokomela habonolo. Mochini o amohetse theknoloji ea ho roala maqhubu a mahareng, a koahela ka lisebelisoa tsa oxide tse kang silicon oxide le niobium oxide joalo-joalo, ka gauge ea botenya ba filimi ho etsa filimi e khabisitsoeng ea optical. Filimi e entsoeng ke magnetron sputtering optical coating machine e na le sekhomaretsi se matla le bohloeki bo phahameng, 'me se ka tšeloa ka lisebelisoa tse sa tšoaneng tse nang le likarolo tse fapaneng ka nako e le' ngoe.