Plasma properties

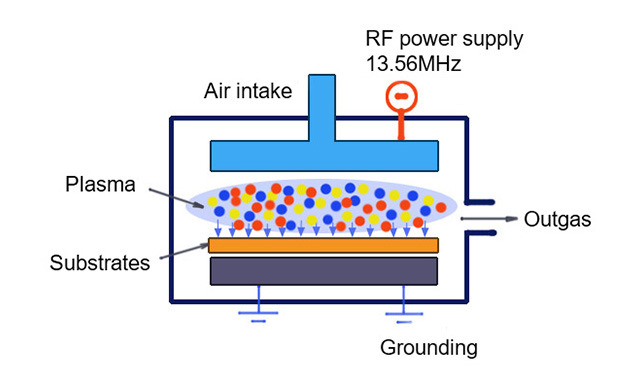

The nature of plasma in plasma-enhanced chemical vapor deposition is that it relies on the kinetic energy of the electrons in the plasma to activate the chemical reactions in the gas phase. Since plasma is a collection of ions, electrons, neutral atoms and molecules, it is electrically neutral at the macroscopic level. In a plasma, a large amount of energy is stored in the internal energy of the plasma. Plasma is originally divided into hot plasma and cold plasma. in PECVD system it is cold plasma which is formed by low pressure gas discharge. This plasma produced by a low pressure discharge below a few hundred Pa is a non-equilibrium gas plasma.

The nature of this plasma is as follow:

(1)Irregular thermal motion of electrons and ions exceeds their directed motion.

(2) Its ionization process is mainly caused by the collision of fast electrons with gas molecules.

(3) The average thermal motion energy of electrons is 1 to 2 orders of magnitude higher than that of heavy particles, such as molecules, atoms, ions and free radicals.

(4) The energy loss after the collision of electrons and heavy particles can be compensated from the electric field between collisions.

It is difficult to characterize a low-temperature nonequilibrium plasma with a small number of parameters, because it is a low-temperature nonequilibrium plasma in a PECVD system, where the electron temperature Te is not the same as the temperature Tj of the heavy particles. In PECVD technology, the primary function of the plasma is to produce chemically active ions and free-radicals. These ions and free-radicals react with other ions, atoms and molecules in the gas phase or cause lattice damage and chemical reactions on the substrate surface, and the yield of active material is a function of electron density, reactant concentration and yield coefficient. In other words, the yield of active material depends on the electric field strength, gas pressure, and the average free range of the particles at the time of collision. As the reactant gas in the plasma dissociates due to the collision of high-energy electrons, the activation barrier of the chemical reaction can be overcome and the temperature of the reactant gas can be reduced. The main difference between PECVD and conventional CVD is that the thermodynamic principles of the chemical reaction are different. The dissociation of gas molecules in the plasma is non-selective, so the film layer deposited by PECVD is completely different from conventional CVD. The phase composition produced by PECVD may be non-equilibrium unique, and its formation is no longer limited by the equilibrium kinetics. The most typical film layer is amorphous state.

PECVD features

(1) Low deposition temperature.

(2) Reduce the internal stress caused by the mismatch of the linear expansion coefficient of the membrane/base material.

(3) The deposition rate is relatively high, especially low temperature deposition, which is conducive to obtaining amorphous and microcrystalline films.

Due to the low temperature process of PECVD, thermal damage can be reduced, mutual diffusion and reaction between the film layer and substrate material can be reduced, etc., so that electronic components can be coated both before they are made or due to the need for rework. For the manufacture of ultra-large scale integrated circuits (VLSI, ULSI), PECVD technology is successfully applied to the formation of silicon nitride film (SiN) as the final protective film after the formation of Al electrode wiring, as well as flattening and the formation of silicon oxide film as interlayer insulation. As thin-film devices, PECVD technology has also been successfully applied to the manufacture of thin-film transistors (TFTs) for LCD displays, etc., using glass as the substrate in the active matrix method. With the development of integrated circuits to larger scale and higher integration and the widely use of compound semiconductor devices, PECVD is required to be performed at lower temperature and higher electron energy processes. To meet this requirement, technologies that can synthesize higher flatness films at lower temperatures are to be developed. The SiN and SiOx films have been studied extensively using ECR plasma and a new plasma chemical vapor deposition (PCVD) technology with a helical plasma, and have reached a practical level in the use of interlayer insulation films for larger scale integrated circuits, etc.

Post time: Nov-08-2022