Plasma khoom

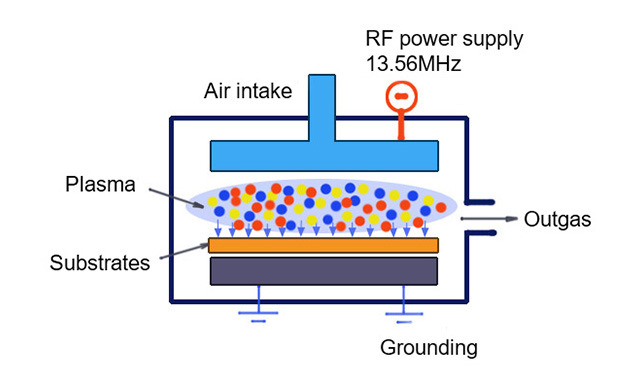

Qhov xwm txheej ntawm plasma hauv plasma-enhanced chemical vapor deposition yog tias nws tso siab rau lub zog kinetic ntawm cov electrons hauv cov ntshav los ua kom cov tshuaj tiv thaiv hauv cov pa roj.Txij li thaum lub plasma yog ib qho kev sau ntawm ions, electrons, nruab nrab atoms thiab molecules, nws yog hluav taws xob nruab nrab ntawm qib macroscopic.Nyob rau hauv lub plasma, ib tug loj npaum li cas ntawm lub zog yog khaws cia nyob rau hauv lub internal zog ntawm lub plasma.Plasma yog Ameslikas muab faib ua plasma kub thiab txias plasma.nyob rau hauv PECVD system nws yog txias plasma uas yog tsim los ntawm tsis tshua muaj siab gas paug.Lub plasma no tsim los ntawm qhov tsis tshua muaj siab tawm hauv qab ob peb puas Pa yog cov roj ntshav tsis sib npaug.

Qhov xwm ntawm cov plasma no yog raws li nram no:

(1) Tsis zoo thermal txav ntawm electrons thiab ions tshaj lawv cov lus qhia.

(2) Nws cov txheej txheem ionization feem ntau yog tshwm sim los ntawm kev sib tsoo ntawm cov hluav taws xob ceev nrog cov roj molecules.

(3) Lub zog nruab nrab ntawm thermal zog ntawm electrons yog 1 mus rau 2 qhov kev txiav txim siab ntau dua li cov khoom hnyav, xws li molecules, atoms, ions thiab dawb radicals.

(4) Lub zog poob tom qab kev sib tsoo ntawm cov hluav taws xob thiab cov khoom hnyav tuaj yeem raug them los ntawm hluav taws xob ntawm kev sib tsoo.

Nws yog ib qho nyuaj rau tus yam ntxwv ntawm qhov kub tsis tshua muaj qhov tsis sib xws hauv cov ntshav nrog cov tsis muaj tsawg, vim tias nws yog qhov kub tsis tshua muaj qhov tsis zoo hauv cov ntshav hauv PECVD qhov system, qhov kub ntawm electron Te tsis zoo ib yam li qhov kub thiab txias Tj ntawm cov khoom hnyav.Hauv PECVD thev naus laus zis, lub luag haujlwm tseem ceeb ntawm cov ntshav ntshav yog tsim cov tshuaj lom neeg ions thiab dawb-radicals.Cov ions thiab cov dawb-radicals hnov qab nrog lwm cov ions, atoms thiab molecules nyob rau hauv cov roj theem los yog ua rau lub lattice puas thiab tshuaj lom neeg tshwm sim nyob rau hauv lub substrate nto, thiab yield ntawm active khoom yog ib tug muaj nuj nqi ntawm electron ceev, reactant concentration thiab yield coefficient.Hauv lwm lo lus, cov txiaj ntsig ntawm cov khoom siv nquag yog nyob ntawm lub zog hluav taws xob, lub zog ntawm cov pa roj, thiab qhov nruab nrab dawb ntawm cov khoom thaum lub sijhawm sib tsoo.Raws li cov roj reactant nyob rau hauv cov ntshav plasma dissociates vim muaj kev sib tsoo ntawm high-zog electrons, lub activation barrier ntawm cov tshuaj tiv thaiv yuav kov yeej thiab qhov kub ntawm cov reactant roj yuav txo tau.Qhov sib txawv tseem ceeb ntawm PECVD thiab cov pa CVD yog qhov ntsuas kub ntawm cov tshuaj tiv thaiv tshuaj sib txawv.Lub dissociation ntawm roj molecules nyob rau hauv lub plasma yog tsis xaiv, yog li cov zaj duab xis txheej deposited los ntawm PECVD yog kiag li txawv los ntawm cov pa CVD.Cov theem muaj pes tsawg leeg tsim los ntawm PECVD tej zaum yuav tsis yog-equilibrium tshwj xeeb, thiab nws tsim tsis txwv los ntawm cov equilibrium kinetics.Cov txheej txheej zaj duab xis feem ntau yog amorphous xeev.

PECVD nta

(1) Tsawg deposition kub.

(2) Txo cov kev ntxhov siab sab hauv los ntawm qhov tsis sib haum xeeb ntawm cov kab sib txuas ntawm cov khoom siv hauv daim nyias nyias.

(3) Lub deposition tus nqi kuj yog siab, tshwj xeeb tshaj yog tsis tshua muaj kub deposition, uas yog haum rau tau txais amorphous thiab microcrystalline films.

Vim yog cov txheej txheem kub ntawm PECVD, thermal puas tuaj yeem txo qis, kev sib nrig sib nqus thiab cov tshuaj tiv thaiv ntawm cov txheej txheem zaj duab xis thiab cov khoom siv substrate tuaj yeem txo, thiab lwm yam, kom cov khoom siv hluav taws xob tuaj yeem coated ob qho tib si ua ntej lawv tsim los yog vim qhov xav tau. rau rework.Rau kev tsim khoom ntawm ultra-loj scale integrated circuits (VLSI, ULSI), PECVD thev naus laus zis tau ua tiav rau kev tsim cov silicon nitride zaj duab xis (SiN) ua cov yeeb yaj kiab tiv thaiv zaum kawg tom qab tsim Al electrode thaiv, nrog rau kev ua kom zoo nkauj thiab kev sib tw. tsim ntawm silicon oxide zaj duab xis raws li interlayer rwb thaiv tsev.Raws li cov khoom siv zaj duab xis nyias, PECVD thev naus laus zis kuj tau ua tiav rau kev tsim cov yeeb yaj kiab nyias nyias (TFTs) rau cov duab LCD, thiab lwm yam, siv iav ua cov txheej txheem hauv cov txheej txheem matrix.Nrog rau kev txhim kho ntawm kev sib xyaw ua ke rau cov nplai loj thiab kev sib koom ua ke ntau dua thiab siv dav siv cov khoom siv semiconductor, PECVD yuav tsum tau ua ntawm qhov kub thiab txias dua thiab cov txheej txheem hluav taws xob ntau dua.Yuav kom ua tau raws li qhov yuav tsum tau ua, thev naus laus zis uas tuaj yeem tsim cov yeeb yaj kiab ntau dua flatness ntawm qhov kub thiab txias yuav tsum tau tsim.Cov yeeb yaj kiab SiN thiab SiOx tau kawm ntau yam siv ECR plasma thiab cov plasma chemical vapor deposition (PCVD) technology tshiab nrog lub helical plasma, thiab tau mus txog qib ua tau zoo hauv kev siv cov yeeb yaj kiab interlayer rwb thaiv tsev rau cov nplai loj sib xyaw ua ke, thiab lwm yam.

Post lub sij hawm: Nov-08-2022