No.1 Isimiso samandla aphezulu pulsed magnetron sputtering

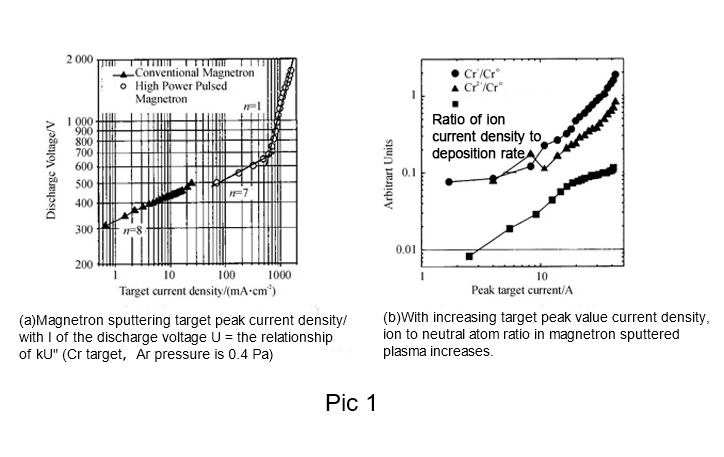

Amandla aphezulu wokuphalaza kwe-magnetron esebenzisa amandla aphezulu aphezulu (ama-oda angu-2-3 obukhulu obungaphezu kokuvamile kwe-magnetron sputtering) kanye nomjikelezo we-pulse duty duty (0.5% -10%) ukuze kuzuzwe amazinga aphezulu okuhlukaniswa kwensimbi (>50%), okuyinto isuselwa ezicini zokuphalaza zikazibuthe, njengoba kuboniswe ku-Pic 1, lapho ukuminyana okuhlosiwe okuphezulu okuhlosiwe kwamanje kuqhathaniswa namandla e-nth exponential we-voltage yokukhipha engu-U, I = kUn (n iwukuhambisana njalo nesakhiwo se-cathode, inkambu kazibuthe nezinto ezibonakalayo).Emazingeni aphansi wamandla (i-voltage ephansi) inani le-n ngokuvamile liphakathi kuka-5 kuya ku-15;nge-voltage yokukhipha ekhulayo, ukuminyana kwamanje kanye nokuminyana kwamandla kukhuphuka ngokushesha, futhi ku-voltage ephezulu inani elingu-n liba ngu-1 ngenxa yokulahlekelwa ukuvaleka kwendawo kazibuthe.Uma ekuminyana kwamandla aphansi, ukukhishwa kwegesi kunqunywa ama-ion egesi asesimweni esivamile sokukhipha i-pulsed discharge;uma amandla amakhulu aminyana, ingxenye yama-ion ensimbi ku-plasma iyanda futhi ezinye izinto ziyashintsha, okukumodi yokuziphalaza, okungukuthi i-plasma igcinwa yi-ionization yezinhlayiya ezifafaziwe ezingathathi hlangothi nama-ion ensimbi yesibili, nama-athomu egesi angenayo. njenge-Ar isetshenziselwa kuphela ukuthungela i-plasma, emva kwalokho izinhlayiya zensimbi ezifafaziwe zifakwe i-ioned eduze kwalapho okuhlosiwe futhi ziphuthunyiswe emuva ukuze zihlasele ithagethi ehlutshiwe ngaphansi kwesenzo sezinkundla zikazibuthe nezikagesi ukuze kugcinwe ukuphuma okuphezulu kwamanje, futhi i-plasma iphakeme kakhulu. izinhlayiya zensimbi ionized.Ngenxa yenqubo yokufafaza komthelela wokushisisa kulokho okuqondiwe, ukuze kuqinisekiswe ukusebenza okuzinzile kokuhlosiwe ezinhlelweni zemboni, ukuminyana kwamandla okusetshenziswe ngokuqondile kumpokophelo angeke kube kukhulu kakhulu, ngokuvamile okupholisa amanzi okuqondile kanye ne-target material conductivity. kufanele ibe esimweni esingu-25 W / cm2 ngezansi, ukupholisa kwamanzi okungaqondile, ukuhanjiswa kwe-thermal okuhlosiwe kumpofu, izinto ezihlosiwe ezibangelwa ukuhlukana ngenxa yokucindezeleka okushisayo noma okuhlosiwe kuqukethe izingxenye ze-alloy ezithambile eziphansi kanye nezinye izimo zokuminyana kwamandla kungaba kuphela 2 ~ 15 W / cm2 ngezansi, ngaphansi kakhulu kwezidingo zokuminyana kwamandla aphezulu.Inkinga yokushisa okuhlosiwe ingaxazululwa ngokusebenzisa ama-pulses aphezulu amancane amancane kakhulu.U-Anders uchaza i-pulsed magnetron sputtering yamandla aphezulu njengohlobo lokufafaza okududuzayo lapho ukuminyana kwamandla aphezulu kudlula isilinganiso samandla esimaphakathi ngama-oda angu-2 ukuya kwangu-3 obukhulu, futhi i-ion sputtering eqondiwe ibusa inqubo yokufafaza, futhi ama-athomu okufafaza okuhlosiwe ahluke kakhulu. .

Cha.2 Izici zamandla aphezulu e-pulsed magnetron sputtering coating deposition

I-high power pulsed magnetron sputtering ingakhiqiza i-plasma enezinga eliphezulu lokuhlukanisa namandla e-ion aphezulu, futhi ingasebenzisa ukucindezela kokuchema ukuze kusheshiswe ama-ion akhokhisiwe, futhi inqubo yokubeka okokumboza ihlaselwe yizinhlayiya zamandla aphezulu, okuwubuchwepheshe obujwayelekile be-IPVD.Amandla e-ion nokusabalalisa kunomthelela obaluleke kakhulu kwikhwalithi yokumboza nokusebenza.

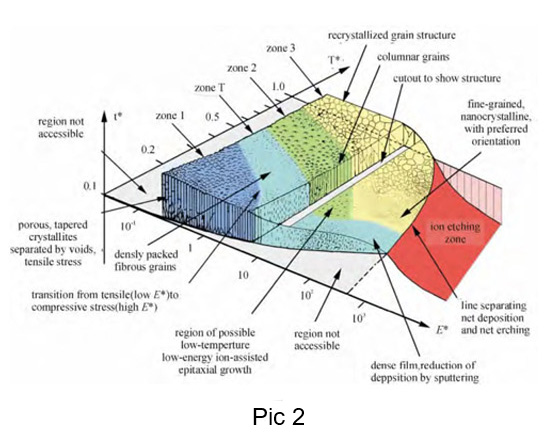

Mayelana ne-IPVD, ngokusekelwe kumodeli edumile yesifunda sesakhiwo sase-Thorton, u-Anders uhlongoze imodeli yesifunda yesakhiwo ehlanganisa ukufakwa kwe-plasma kanye nokushumeka kwe-ion, yandisa ubudlelwano phakathi kwesakhiwo sokumboza nezinga lokushisa nomfutho womoya kumodeli yesifunda sesakhiwo saseThorton ebuhlotsheni phakathi kwesakhiwo sokumboza, izinga lokushisa kanye namandla e-ion, njengoba kukhonjisiwe ku-Pic 2. Endabeni yokufakwa kwe-ion yamandla aphansi, isakhiwo sokumboza sivumelana nemodeli yendawo yesakhiwo se-Thorton.Ngokukhuphuka kwezinga lokushisa lokubeka, ukuguquka kusuka esifundeni 1 (amakristalu e-fiber avulekile) kuya esifundeni T (amakristalu e-fiber aminyene), isifunda 2 (amakristalu ekholomu) kanye nesifunda 3 (isifunda sokuvuselela kabusha);ngokwanda kwamandla e-ion ion, izinga lokushisa lokushintsha ukusuka esifundeni 1 ukuya esifundeni T, isifunda 2 kanye nesifunda sesi-3 liyehla.I-high-density fiber crystals namakristalu ekholomu angalungiswa ekushiseni okuphansi.Lapho amandla ama-ion afakiwe enyuka aze afike ku-1-10 eV, ukuqhunyiswa kwebhomu kanye nokucwiliswa kwama-ion endaweni ye-coatings efakiwe kuyathuthukiswa futhi ukujiya kwezimbobo kuyakhula.

No.3 Ukulungiswa kongqimba oluqinile lokunamathela ngamandla amakhulu obuchwepheshe be-pulsed magnetron sputtering

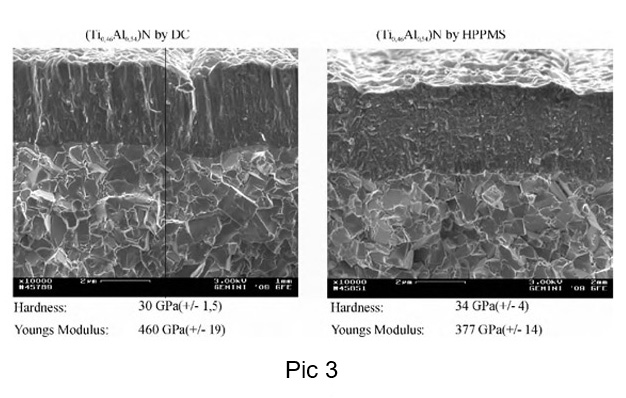

I-coating elungiselelwe amandla aphezulu e-pulsed magnetron sputtering technology iminyene, enezakhiwo ezingcono zemishini kanye nokuzinza okuphezulu kwezinga lokushisa.Njengoba kukhonjisiwe ku-Pic 3, i-magnetron evamile i-sputtered TiAlN coating iyi-columnar crystal structure enobulukhuni be-30 GPa kanye ne-Young's modulus engu-460 GPa;ukufakwa kwe-HIPIMS-TiAlN kungubulukhuni obungama-34 GPa kuyilapho imoduli ye-Young ingu-377 GPa;isilinganiso phakathi kokuqina kanye ne-Young's modulus isilinganiso sokuqina kokunamathela.Ukuqina okuphezulu kanye nemodulus encane ye-Young kusho ukuqina okungcono.Ukufakwa kwe-HIPIMS-TiAlN kunokuzinza okungcono kwezinga lokushisa eliphezulu, nesigaba se-AlN esiyi-hexagonal esinetha embotsheni evamile ye-TiAlN ngemva kokwelashwa kwe-annealing lokushisa eliphezulu ku-1,000 °C amahora angu-4.Ukuqina kokugqoka kuncipha ekushiseni okuphezulu, kuyilapho ukugqoka kwe-HIPIMS-TiAlN kuhlala kungashintshile ngemva kokwelashwa kokushisa ngesikhathi esifanayo sokushisa kanye nesikhathi.I-HIPIMS-TiAlN yokugqoka nayo inezinga lokushisa eliphezulu lokuqalisa kwe-oxidation yokushisa ephezulu kunokwemboza okuvamile.Ngakho-ke, ukugqoka kwe-HIPIMS-TiAlN kubonisa ukusebenza okungcono kakhulu kumathuluzi okusika ngesivinini esikhulu kunamanye amathuluzi ahlanganisiwe alungiselelwe inqubo ye-PVD.

Isikhathi sokuthumela: Nov-08-2022