No.1 Lub hauv paus ntsiab lus ntawm lub zog siab pulsed magnetron sputtering

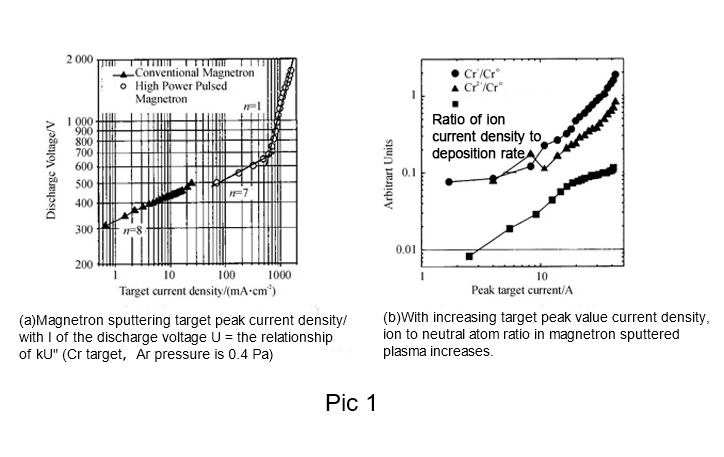

Lub tshuab hluav taws xob siab siab magnetron sputtering cov txheej txheem siv lub zog siab pulse siab (2-3 qhov kev txiav txim siab siab dua li cov qauv magnetron sputtering) thiab qis pulse lub voj voog (0.5% -10%) kom ua tiav cov hlau tsis sib xws (> 50%), uas yog muab los ntawm magnetron sputtering yam ntxwv, raws li qhia nyob rau hauv Pic 1, qhov twg lub ncov lub hom phiaj tam sim no ceev kuv yog proportional rau lub exponential nth hwj chim ntawm tus paug voltage U, I = kUn (n yog ib tug tas mus li hais txog lub cathode qauv, magnetic teb. thiab cov khoom siv).Thaum qis zog ceev (tsis tshua muaj hluav taws xob) tus nqi n feem ntau yog nyob rau hauv thaj tsam ntawm 5 txog 15;Nrog rau txoj kev nce hluav taws xob nce ntxiv, qhov ceev ceev tam sim no thiab lub zog hluav taws xob nce sai, thiab ntawm cov hluav taws xob ntau dhau los ua 1 vim yog qhov poob ntawm kev sib nqus teb kaw.Yog hais tias nyob rau hauv tsawg zog ceev, cov pa paug yog txiav txim los ntawm cov roj ions uas yog nyob rau hauv ib txwm pulsed paug hom;Yog hais tias nyob rau hauv siab zog ceev, qhov kev faib ua feem ntawm cov hlau ions nyob rau hauv lub plasma nce thiab ib co ntaub ntawv hloov, uas yog nyob rau hauv tus kheej-sputtering hom, piv txwv li Lub plasma yog tswj los ntawm ionization ntawm sputtered nruab nrab hais thiab theem nrab hlau ions, thiab inert gas atoms. xws li Ar tsuas yog siv los hlawv cov ntshav ntshav, tom qab ntawd cov khoom siv hlau sputtered yog ionized nyob ze ntawm lub hom phiaj thiab nrawm rov qab mus rau lub hom phiaj sputtered nyob rau hauv qhov kev txiav txim ntawm cov hlau nplaum thiab hluav taws xob ua kom lub siab tam sim no tawm, thiab cov ntshav siab heev. ionized hlau hais.Vim lub sputtering txheej txheem ntawm cov cua kub nyhuv ntawm lub hom phiaj, thiaj li yuav ua kom ruaj khov ntawm lub hom phiaj nyob rau hauv industrial daim ntaub ntawv, lub hwj chim ceev ncaj qha mus rau lub hom phiaj tsis tuaj yeem loj heev, feem ntau ncaj qha dej txias thiab cov khoom siv thermal conductivity. yuav tsum yog nyob rau hauv cov ntaub ntawv ntawm 25 W / cm2 hauv qab no, indirect dej txias, lub hom phiaj cov khoom thermal conductivity yog tsis zoo, lub hom phiaj cov ntaub ntawv uas tshwm sim los ntawm fragmentation vim thermal stress los yog lub hom phiaj cov ntaub ntawv uas tsis muaj volatile alloy Cheebtsam thiab lwm yam teeb meem ntawm lub hwj chim ceev tsuas yog nyob rau hauv 2 ~ 15 W / cm2 hauv qab no, deb tshaj qhov yuav tsum tau muaj zog ceev ceev.Qhov teeb meem ntawm lub hom phiaj overheating tuaj yeem daws tau los ntawm kev siv lub zog nqaim heev.Anders txhais tau hais tias lub zog siab zog pulsed magnetron sputtering yog ib hom kev sib txuas ntawm qhov chaw uas lub zog siab ceev tshaj qhov nruab nrab lub zog ceev los ntawm 2 mus rau 3 qhov kev txiav txim ntawm qhov loj, thiab lub hom phiaj ion sputtering dominates tus txheej txheem sputtering, thiab lub hom phiaj sputtering atoms yog heev dissociated. .

No.2 Cov yam ntxwv ntawm lub zog siab pulsed magnetron sputtering txheej deposition

Lub zog siab zog pulsed magnetron sputtering tuaj yeem tsim cov ntshav nrog qhov sib txawv ntawm qhov siab thiab lub zog ion siab, thiab tuaj yeem siv lub siab tsis zoo los ua kom cov ions raug them, thiab txheej txheej txheej txheej txheej txheej tau tawg los ntawm cov khoom siv hluav taws xob siab, uas yog cov cuab yeej siv IPVD.Lub zog ion thiab kev faib tawm muaj qhov cuam tshuam tseem ceeb rau cov txheej txheem zoo thiab kev ua haujlwm.

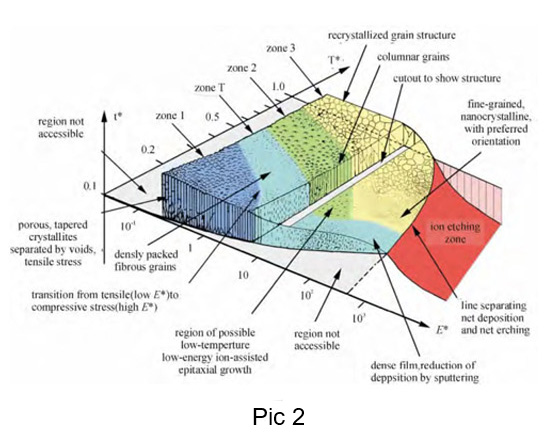

Hais txog IPVD, raws li tus qauv nto moo Thorton cov qauv hauv cheeb tsam, Anders tau npaj cov qauv hauv cheeb tsam uas suav nrog cov plasma deposition thiab ion etching, txuas ntxiv kev sib raug zoo ntawm txheej txheej thiab kub thiab huab cua siab nyob rau hauv Thorton structural cheeb tsam qauv rau kev sib raug zoo ntawm txheej txheej, kub thiab ion zog, raws li qhia nyob rau hauv Pic 2. Nyob rau hauv cov ntaub ntawv ntawm tsawg zog ion deposition txheej, txheej txheej conforms rau Thorton qauv cheeb tsam qauv.Nrog rau qhov nce ntawm qhov kub thiab txias, kev hloov pauv ntawm cheeb tsam 1 (loos ntxeem tau fiber ntau) mus rau thaj tsam T (nruj fiber ntau muaju), thaj tsam 2 (kaum muaju) thiab cheeb tsam 3 ( cheeb tsam recrystallization);Nrog rau qhov nce ntawm kev tso tawm ion zog, qhov kev hloov pauv kub ntawm thaj tsam 1 mus rau thaj tsam T, cheeb tsam 2 thiab cheeb tsam 3 txo qis.Lub high-density fiber crystals thiab columnar crystals tuaj yeem npaj tau ntawm qhov kub thiab txias.Thaum lub zog ntawm deposited ions nce mus rau qhov kev txiav txim ntawm 1-10 eV, lub foob pob thiab etching ntawm ions ntawm deposited coatings nto yog txhim khu kev qha thiab lub thickness ntawm coatings yog nce.

No.3 Kev npaj txheej txheej nyuaj los ntawm lub zog siab zog pulsed magnetron sputtering tshuab

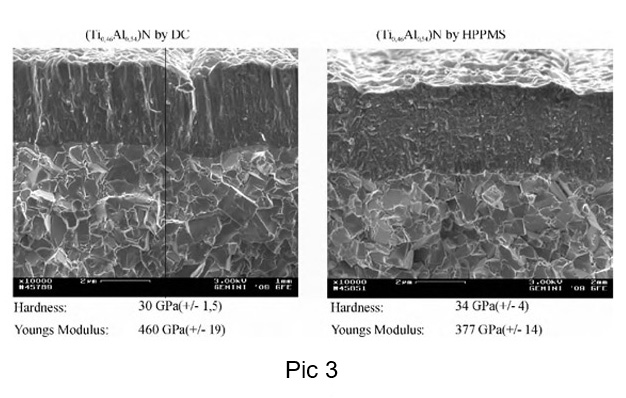

Cov txheej txheej npaj los ntawm lub zog siab pulsed magnetron sputtering tshuab yog denser, nrog cov khoom siv zoo dua qub thiab kub kub stability.Raws li pom nyob rau hauv Pic 3, cov pa magnetron sputtered TiAlN txheej yog ib tug columnar siv lead ua qauv nrog ib tug hardness ntawm 30 GPa thiab ib tug hluas modulus ntawm 460 GPa;HIPIMS-TiAlN txheej yog 34 GPa hardness thaum Young's modulus yog 377 GPa;qhov piv ntawm hardness thiab Young's modulus yog ib qho kev ntsuas ntawm lub toughness ntawm txheej.Siab hardness thiab me me Young's modulus txhais tau tias zoo dua toughness.HIPIMS-TiAlN txheej muaj qhov kub thiab txias zoo dua, nrog AlN hexagonal theem precipitated nyob rau hauv cov pa TiAlN txheej tom qab kub annealing kev kho mob ntawm 1,000 ° C rau 4 h.Lub hardness ntawm txheej txo qis ntawm qhov kub thiab txias, thaum HIPIMS-TiAlN txheej tseem tsis hloov tom qab kev kho cua sov ntawm tib qhov kub thiab sijhawm.HIPIMS-TiAlN txheej kuj muaj qhov pib kub ntawm qhov kub thiab txias oxidation ntau dua li cov txheej txheem.Yog li ntawd, HIPIMS-TiAlN txheej qhia tau hais tias kev ua tau zoo dua hauv cov cuab yeej siv ceev ceev dua li lwm cov cuab yeej coated npaj los ntawm PVD txheej txheem.

Post lub sij hawm: Nov-08-2022