No.1 Kumu o ka mana kiʻekiʻe pulsed magnetron sputtering

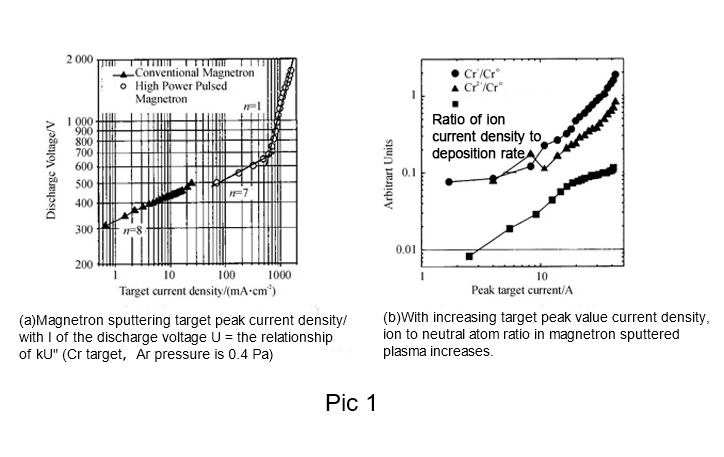

Hoʻohana ka mana kiʻekiʻe pulsed magnetron sputtering i ka mana pulse peak kiʻekiʻe (2-3 kauoha o ka nui ma mua o ka magnetron sputtering maʻamau) a me ka haʻahaʻa pulse duty cycle (0.5% -10%) e hoʻokō i nā helu dissociation metala kiʻekiʻe (> 50%), ka mea. loaʻa mai ka magnetron sputtering mau hiʻohiʻona, e like me ka mea i hōʻike ʻia ma Pic 1, kahi o ka peak target current density I like me ka exponential nth mana o ka mana hoʻokuʻu U, I = kUn (n he mea mau e pili ana i ka hoʻolālā cathode, māla magnetic. a me nā mea waiwai).Ma nā ha'aha'a mana ha'aha'a (volta ha'aha'a) ma'amau ka helu n ma waena o 5 a 15;me ka piʻi ʻana o ka volta hoʻokuʻu, piʻi wikiwiki ka nui o kēia manawa a me ka nui o ka mana, a ma ke kiʻekiʻe ka nui o ka helu n e lilo i 1 ma muli o ka nalowale o ka hoʻopaʻa ʻana i ka māla magnetic.Inā ma nā haʻahaʻa mana haʻahaʻa, hoʻoholo ʻia ka hoʻokuʻu kinoea e nā ion kinoea i loko o ke ʻano hoʻokuʻu pulsed maʻamau;inā ma nā density mana kiʻekiʻe, piʻi ka hapa o nā ion metala i loko o ka plasma a hoʻololi kekahi mau mea, aia ia i ke ʻano hoʻoheheʻe ponoʻī, ie. e like me Ar hoʻohana wale ʻia e puhi i ka plasma, a ma hope iho ua hoʻokaʻawale ʻia nā ʻāpana metala sputtered kokoke i ka pahu hopu a hoʻihoʻi hou i ka pahu i ka pahu sputtered ma lalo o ka hana a nā māla magnetic a me ka uila e mālama i ka hoʻokuʻu ʻana o kēia manawa, a ʻoi loa ka plasma. ʻāpana metala ionized.Ma muli o ke kaʻina hana sputtering o ka hopena wela ma ka pahu hopu, i mea e hōʻoia ai i ka hana paʻa o ka pahuhopu i nā noi ʻoihana, ʻaʻole hiki ke nui loa ka mana o ka mana i hoʻopili pololei ʻia i ka pahu hopu, maʻamau ka hoʻoluʻu wai a me ka conductivity thermal material. pono i ka hihia o 25 W / cm2 ma lalo, hoʻoluʻu wai ʻole, ʻilihune ka mea i hoʻopaʻa ʻia i ka thermal conductivity, nā mea i hoʻokumu ʻia e ka ʻāpana ma muli o ke koʻikoʻi wela a i ʻole nā mea i hoʻopaʻa ʻia i nā mea haʻahaʻa haʻahaʻa i loko 2 ~ 15 W / cm2 ma lalo, ma lalo o nā koi o ka mana kiʻekiʻe.Hiki ke hoʻopau ʻia ka pilikia o ka wela wela ma ka hoʻohana ʻana i nā pulses mana kiʻekiʻe.Ua wehewehe ʻo Anders i ka mana kiʻekiʻe pulsed magnetron sputtering e like me ke ʻano o ka pulsed sputtering kahi i ʻoi aku ka nui o ka mana kiʻekiʻe ma mua o ka mana awelika ma ka 2 a 3 mau kauoha o ka nui, a ʻo ka pahuhopu ion sputtering e hoʻomalu i ke kaʻina sputtering, a ua hoʻokaʻawale loa nā atoms sputtering target. .

No.2 Nā ʻano o ka mana kiʻekiʻe pulsed magnetron sputtering coating deposition

Hiki i ka mana kiʻekiʻe pulsed magnetron sputtering hiki ke hana i ka plasma me ka kiʻekiʻe dissociation rate a me ka ikehu ion kiʻekiʻe, a hiki ke hoʻopili i ke kaomi bias e hoʻolalelale i nā ion i hoʻopiʻi ʻia, a ua hoʻomake ʻia ke kaʻina deposition coating e nā mea ikaika kiʻekiʻe, ʻo ia ka ʻenehana IPVD maʻamau.He hopena koʻikoʻi ko ka ikehu ion a me ka hāʻawi ʻana i ka maikaʻi o ka uhi a me ka hana.

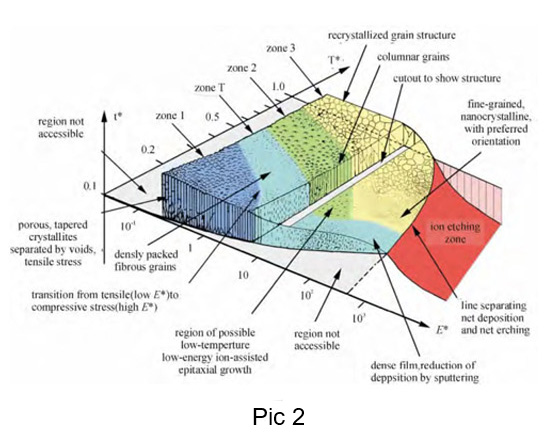

E pili ana i ka IPVD, ma muli o ke kumu hoʻohālike kaulana ʻo Thorton structural region, ua hāʻawi ʻo Anders i kahi kumu hoʻohālike ʻāina e pili ana i ka plasma deposition a me ka ion etching, e hoʻonui i ka pilina ma waena o ke ʻano o ka uhi ʻana a me ka mahana a me ke kaomi ʻana o ka ea i ka ʻāpana ʻāina ʻo Thorton i ka pilina ma waena o ka hoʻopili ʻana. ka wela a me ka ikehu ion, e like me ia i hoikeia ma Pic 2. I ka hihia o ka hoolele ana i ka ikehu ikehu haahaa, ua kulike ka hale hoahu me ke kükohu o ke kaona hale Thorton.Me ka piʻi ʻana o ka mahana deposition, ʻo ka hoʻololi ʻana mai ka ʻāpana 1 (nā kristal porous porous) a i ka ʻāpana T (nā kristal fiber paʻa), ka ʻāpana 2 (nā kristal columnar) a me ka ʻāpana 3 (ʻāpana recrystallization);me ka piʻi ʻana o ka ikehu ion deposition, e emi ana ka mahana hoʻololi mai ka ʻāina 1 a i ka ʻāpana T, ka ʻāpana 2 a me ka ʻāpana 3.Hiki ke hoʻomākaukau i nā kristal fiber kiʻekiʻe a me nā kolamu kolamu i ka haʻahaʻa haʻahaʻa.Ke piʻi aʻe ka ikehu o nā ion i waiho ʻia i ke kauoha o 1-10 eV, e hoʻonui ʻia ka pōʻino a me ke kahakaha ʻana o nā ion ma ka ʻili o nā uhi i waiho ʻia a hoʻonui ʻia ka mānoanoa o nā uhi.

No.3 Ka hoʻomākaukau ʻana i ka papa uhi paʻakikī e ka mana kiʻekiʻe pulsed magnetron sputtering ʻenehana

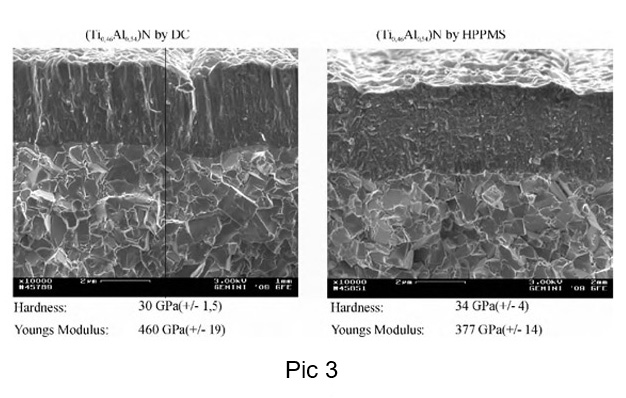

ʻO ka uhi i hoʻomākaukau ʻia e ka mana kiʻekiʻe pulsed magnetron sputtering ʻenehana ʻoi aku ka denser, me ka ʻoi aku ka maikaʻi o nā waiwai mechanical a me ke kūpaʻa wela kiʻekiʻe.E like me ka mea i hōʻike ʻia ma Pic 3, ʻo ka magnetron sputtered TiAlN coating maʻamau he ʻano aniani kolamu me ka paʻakikī o 30 GPa a me ka modulus o Young o 460 GPa;ʻo ka uhi ʻana o HIPIMS-TiAlN he 34 GPa paʻakikī a ʻo ka modulus o ka Young he 377 GPa;ʻO ka lakio ma waena o ka paʻakikī a me ka modulus Young kahi ana o ka paʻakikī o ka uhi.ʻOi aku ka paʻakikī a ʻoi aku ka liʻiliʻi o Young's modulus ʻoi aku ka paʻakikī.ʻO ka uhi ʻana o HIPIMS-TiAlN ʻoi aku ka maikaʻi o ke kūpaʻa wela kiʻekiʻe, me ka AlN hexagonal phase precipitated i loko o ka uhi TiAlN maʻamau ma hope o ka mālama ʻana i ka annealing kiʻekiʻe ma 1,000 °C no 4 mau hola.Ke emi nei ka paʻakikī o ka uhi ʻana i ka wela kiʻekiʻe, ʻoiai ʻo ka uhi ʻana o HIPIMS-TiAlN ʻaʻole i hoʻololi ʻia ma hope o ka mālama ʻana i ka wela ma ka mahana like a me ka manawa.ʻO ka uhi ʻana o HIPIMS-TiAlN ʻoi aku ka kiʻekiʻe o ka hoʻomaka ʻana o ka wela wela ma mua o ka uhi maʻamau.No laila, hōʻike ka uhi HIPIMS-TiAlN i ka hana ʻoi aku ka maikaʻi ma nā mea hana ʻoki kiʻekiʻe ma mua o nā mea hana i uhi ʻia i hoʻomākaukau ʻia e ka hana PVD.

Ka manawa hoʻouna: Nov-08-2022