No.1 Umgaqo wamandla aphezulu epulsed magnetron sputtering

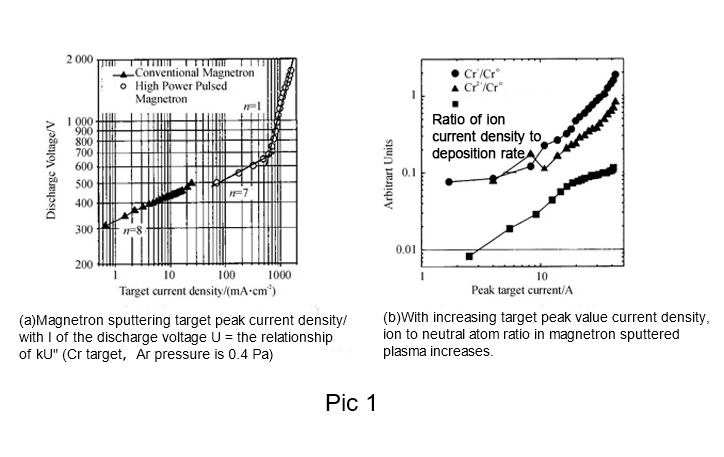

Amandla aphezulu epulsed magnetron sputtering technique esebenzisa amandla aphezulu epulse (2-3 orders of manitude above common magnetron sputtering) kunye nomjikelo ophantsi womsebenzi wepulse (0.5% -10%) ukuphumeza amazinga aphezulu okuqhawula intsimbi (>50%), ethatyathwe kwi-magnetron sputtering, i-pic sputter sputter yangoku, eboniswe kwi-pic target sputter. ilingana ne-exponential nth amandla ombane wokukhupha u-U, I = kUn (n yinto eqhubekayo ehambelana nesakhiwo se-cathode, intsimi yamagnetic kunye nezinto eziphathekayo). Kwimixinano yamandla aphantsi (i-voltage ephantsi) ixabiso le-n lidla ngokuba kuluhlu lwe-5 ukuya kwi-15; ngokunyuka kwamandla ombane okukhutshwayo, ukuxinana kwangoku kunye nokuxinana kwamandla kwanda ngokukhawuleza, kwaye kwi-voltage ephezulu ixabiso le-n liba yi-1 ngenxa yokulahleka kokuvalelwa kwemagnethi. Ukuba kuxinzelelo lwamandla aphantsi, ukukhutshwa kwegesi kuchongwa yi-ion yegesi ekwimo yesiqhelo yokukhupha i-pulsed; ukuba kuxinaniso lwamandla aphezulu, umlinganiselo we-ion zetsimbi kwiplasma uyanda kwaye ezinye izinto ziyatshintsha, ezikwimowudi yokuziphalaza, oko kukuthi, i-plasma igcinwa yi-ionization yamasuntswana angathathi hlangothi athathiweyo kunye nee-ion zetsimbi yesibini, kunye ne-athomu yegesi engasebenziyo njenge-Ar isetyenziselwa kuphela ukuvutha iplasma ephuhliweyo kwaye emva koko i-athomu ethagethiweyo ihlanjululwe kufutshane ne-athomu. umva ukubhobhoza ekujoliswe kuyo sputtered phantsi kwesenzo samandla kazibuthe kunye nombane ukugcina ukukhutshwa kwangoku okuphezulu, kwaye i-plasma i-ionized particles yensimbi. Ngenxa yenkqubo yokutshiza isiphumo sokufudumeza ekujoliswe kuyo, ukuze kuqinisekiswe ukusebenza okuzinzileyo kokujoliswe kuko kwizicelo zemizi-mveliso, uxinaniso lwamandla olusetyenziswa ngokuthe ngqo ekujoliswe kulo alunakuba lukhulu kakhulu, ngokubanzi ukupholisa kwamanzi ngokuthe ngqo kunye nokujoliswe kuko kwe-thermal conductivity kufuneka kube kwimeko ye-25 W / cm2 engezantsi, ukupholisa kwamanzi okungathanga ngqo, ugxininiso lwamandla olujoliswe ngokuthe ngqo olujoliswe ekujoliswe kulo alunakuba lukhulu kakhulu, ukupholisa kwamanzi ngokuthe ngqo kunye nokujoliswe kuyo kwi-thermal conductivity kufuneka ibe kwimeko ye-25 W / cm2 ngezantsi, ukupholisa kwamanzi okungathanga ngqo, into ekujoliswe kuyo ekujoliswe kuyo iqulethe izinto ezijoliswe kuyo ezijoliswe kuxinzelelo oluphantsi okanye i-targm ephantsi yoxinzelelo. amacandelo engxubevange eguquguqukayo kunye nezinye iimeko zoxinaniso lwamandla zinokuba kuphela kwi-2 ~ 15 W / cm2 ngezantsi, kude ngaphantsi kweemfuno zoxinano lwamandla aphezulu. Ingxaki yokutshisa okujoliswe kuko ingasonjululwa ngokusebenzisa iipulse zamandla ezimxinwa kakhulu. UAnders uchaza amandla aphezulu epulsed magnetron sputtering njengohlobo lokugafaza kwepulsed apho amandla oxinaniso agqithise umndilili woxinaniso lwamandla nge-odolo ezi-2 ukuya kwezi-3 zobukhulu, kwaye i-ion ekujoliswe kuyo ilawula inkqubo yokutshiza, kwaye ekujoliswe kuko okugafazayo kunxulunyaniswa kakhulu neeathom ezidityanisiweyo.

No.2 Iimpawu zamandla aphezulu epulsed magnetron sputtering coating deposition

Amandla aphezulu e-pulsed magnetron sputtering anokuvelisa i-plasma enezinga eliphezulu lokuqhawula kunye namandla aphezulu e-ion, kwaye angafaka uxinzelelo lwe-bias ukukhawulezisa i-ion ehlawulisiweyo, kunye nenkqubo yokubeka i-coating ibhobhozwa ngamasuntswana anamandla aphezulu, obuchwephesha obuqhelekileyo be-IPVD. Amandla e-ion kunye nokusabalalisa kunempembelelo ebaluleke kakhulu kumgangatho wokugquma kunye nokusebenza.

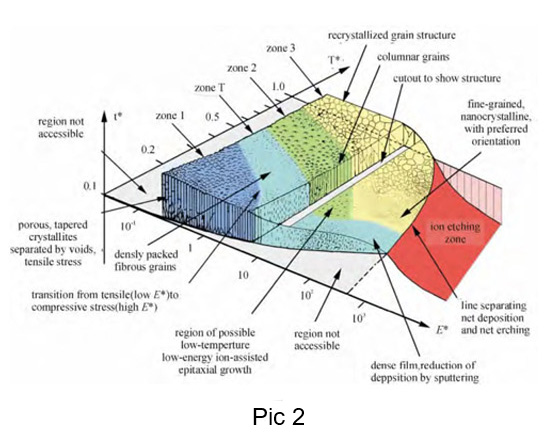

Malunga ne-IPVD, esekelwe kwimodeli yommandla wesakhiwo odumileyo weThorton, uAnders ucebise imodeli yommandla wolwakhiwo obandakanya ukubekwa kweplasma kunye ne-ion etching, yandisa ubudlelwane phakathi kwesakhiwo sokugquma kunye nobushushu kunye noxinzelelo lomoya kwimodeli yengingqi yesakhiwo seThorton ukuya kubudlelwane phakathi kolwakhiwo lokwaleka, ubushushu kunye namandla e-ion, njengoko kubonisiwe kwiPic 2. Kwimeko yolwakhiwo lwe-coating ephantsi, imodeli ye-conform ye-corton imodeli. Ngokunyuka kweqondo lokushisa lokubeka, utshintsho olusuka kwingingqi ye-1 (i-porous fiber crystals) ukuya kwi-T (i-dense fiber crystals), i-2 (i-columnar crystals) kunye nommandla we-3 (ummandla we-recrystallization); ngokunyuka kwamandla e-ion yokubeka, ubushushu benguqu ukusuka kwingingqi 1 ukuya kwingingqi T, ummandla 2 kunye nommandla 3 uyancipha. I-crystals ye-fiber crystals ephezulu kunye ne-columnar crystals inokulungiswa kwiqondo lokushisa eliphantsi. Xa amandla eeoni ezidipozithiweyo enyuka ukuya kumyalelo we-1-10 eV, ukuqhushumba kwebhombu kunye nokubotshwa kweeyoni kwindawo yokwaleka ediphozithiweyo kuphuculwe kwaye ubukhulu bezinto zokwaleka buyanda.

No.3 Ukulungiswa koqweqwe olunzima lokugquma ngamandla aphezulu epulsed magnetron sputtering technology

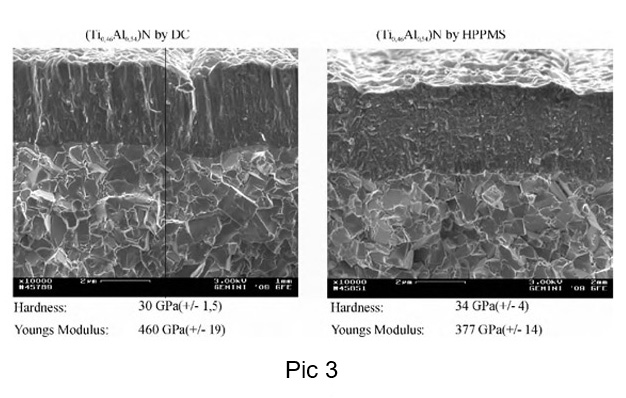

I-coating elungiselelwe ngamandla aphezulu e-pulsed magnetron sputtering teknoloji i-denser, eneempawu ezingcono zoomatshini kunye nokuzinza okuphezulu kobushushu. Njengoko kubonisiwe kwi-Pic 3, i-magnetron eqhelekileyo i-sputtered i-TiAlN yokugqoka i-columnar crystal structure kunye nobunzima be-30 GPa kunye ne-Young's modulus ye-460 GPa; i-HIPIMS-TiAlN yokugqoka i-34 ye-GPa yobunzima ngelixa i-modulus ye-Young i-377 GPa; umlinganiselo phakathi kobulukhuni kunye nemodyuli yoNcinci ngumlinganiselo wokuqina kwengubo. Ubulukhuni obuphezulu kunye nemodyuli encinci ye-Young's modulus ithetha ukuqina okungcono. Ukufakwa kwe-HIPIMS-TiAlN kunozinzo olungcono lobushushu obuphezulu, kunye nesigaba se-AlN esine-hexagonal sigqithise kwi-coating ye-TiAlN eqhelekileyo emva konyango oluphezulu lwe-annealing kwi-1,000 °C kwi-4 h. Ubunzima bengubo buyancipha kwiqondo lokushisa eliphezulu, ngelixa i-HIPIMS-TiAlN yokugqoka ihlala ingatshintshi emva kokunyangwa kobushushu kwiqondo lokushisa elifanayo kunye nexesha. I-HIPIMS-TiAlN yokwambathisa nayo inobushushu obuphezulu bokuqala kobushushu obuphezulu be-oxidation kunokwaleka okuqhelekileyo. Ngoko ke, i-HIPIMS-TiAlN yokugqoka ibonisa ukusebenza okungcono kakhulu kwizixhobo zokusika ngesantya esiphezulu kunezinye izixhobo ezigqunywe yinkqubo ye-PVD.

Ixesha lokuposa: Nov-08-2022