No.1 Nheyo yesimba guru pulsed magnetron sputtering

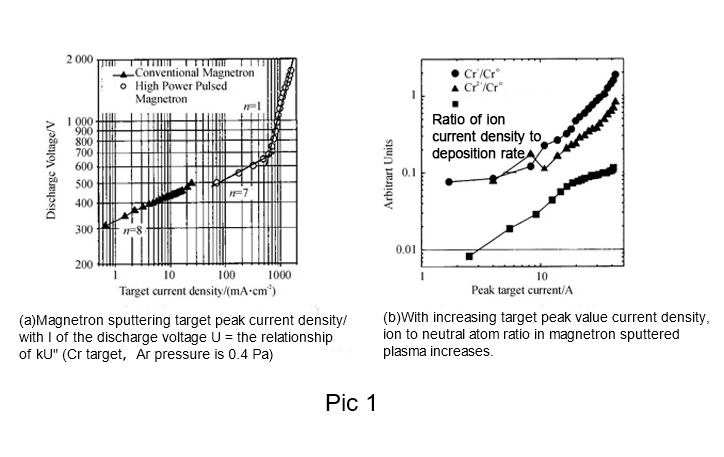

Iyo yakakwira simba pulsed magnetron sputtering nzira inoshandisa yakakwirira peak pulse simba (2-3 maodha ehukuru akakwira kupfuura yakajairwa magnetron sputtering) uye yakaderera pulse duty cycle (0.5% -10%) kuwana yakakwirira simbi dissociation rates (> 50%), iyo inotorwa kubva kune magineti 2-3 yehukuru yakakwira kupfuura yakajairwa magnetron sputtering) uye yakaderera pulse duty cycle (0.5% -10%) kuwana yakakwira simbi dissociation rates (> 50%), iyo inotorwa kubva kune magineti magineti, 1 ikozvino inoratidzwa muPic pensiak sputter. inoenderana neexponential nth simba rekuburitsa voltage U, I = kUn (n inogara inoenderana nekathodhi chimiro, magineti uye zvinhu). Pamagetsi mashoma emagetsi (low voltage) kukosha kwen kunowanzova pakati pe5 kusvika ku15; nekuwedzera kwekubuda kwevoltage, ikozvino density uye simba density inowedzera nekukurumidza, uye pahigh voltage iyo n kukosha inova 1 nekuda kwekurasikirwa kwemagineti kuvharirwa. Kana pakaderera simba densities, kubuda gasi kunotarwa negasi ions iri muyakajairika pulsed discharge mode; kana pasimba resimba guru, chikamu chesimbi ions muplasma chinowedzera uye zvimwe zvinhu zvinochinja, zviri mu-self-sputtering mode, kureva kuti plasma inochengetwa neionization yezvikamu zvakasvibiswa zvakasvibiswa uye maion echipiri esimbi, uye maatomu egasi anert akaita seAr anoshandiswa chete kubatidza plasma yakaputsika uye simbi inoiswa pedyo dzokera kunobhomba iyo sputtered target pasi pechiito chemagnetic nemagetsi minda kuchengetedza yakakwira ikozvino kubuda, uye iyo plasma yakanyanya ionized metal particles. Nekuda kweiyo sputtering maitiro ekudziya kwekuita pane chinangwa, kuitira kuti ive nechokwadi chekushanda kwakasimba kwechinangwa mumaindasitiri ekushandisa, simba remagetsi rinoiswa zvakananga kune chinangwa hachigone kuve rakakura, kazhinji kutonhora kwemvura yakananga uye inonangwa yemafuta ekupisa kunofanirwa kunge kuri mune 25 W / cm2 pazasi, kutonhora kwemvura isina kunanga, chinangwa chechinhu chinopisa chinopisa chinokonzereswa nekushomeka kwezvinhu zvinokonzeresa. volatile alloy components uye dzimwe nyaya dzesimba density inogona kungova mu 2 ~ 15 W / cm2 pazasi, kure pasi pezvinodiwa zvehukuru hwesimba. Dambudziko rechinangwa chekupisa rinogona kugadziriswa nekushandisa yakanyanya kutetepa yakakwirira simba pulses. Anders anotsanangura high-power pulsed magnetron sputtering serudzi rwekupuruzirwa kwesimba uko simba repamusoro rinodarika avhareji yesimba remagetsi ne2 kusvika ku3 maodha ehukuru, uye iyo inonangwa yekupuruzira inotonga maitiro ekupuruzira, uye chinangwa chekupfapfaidza maatomu akabatana zvakanyanya.

No.2 Hunhu hwepamusoro simba pulsed magnetron sputtering coating deposition

High power pulsed magnetron sputtering inogona kuburitsa plasma ine high dissociation rate uye yakakwira ion simba, uye inogona kushandisa bias pressure kuti ikurumidze ions inochajwa, uye iyo coating deposition process inoputirwa neakakwira-simba zvidimbu, inova yakajairika IPVD tekinoroji. Iyo ion simba uye kugovera kune yakakosha mhedzisiro pamhando yekuputira uye kuita.

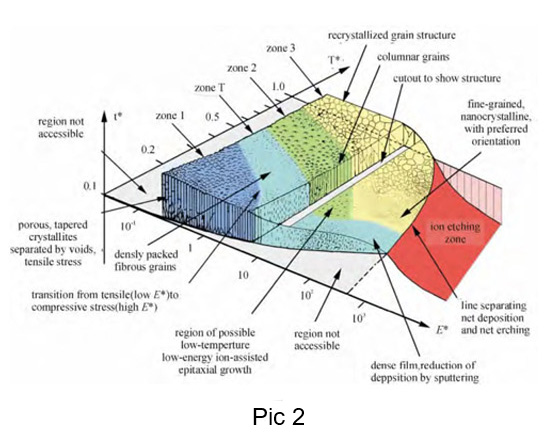

Nezve IPVD, zvichibva pane yakakurumbira Thorton structural region modhi, Anders akakurudzira dhizaini yemodhiyo inosanganisira plasma deposition uye ion etching, yakawedzera hukama pakati peiyo coating chimiro uye tembiricha uye kumanikidza kwemhepo muThorton structural region modhi kune hukama pakati pekupfekedza chimiro, tembiricha uye ion simba, sezvakaratidzwa muPic 2. Kana iri nyaya yekudzikisa simba rekubatanidza dhizaini, dhizaini reiyo corton chimiro. Nekuwedzera kwekushisa kwekuisa, kushanduka kubva munharaunda 1 (yakasununguka porous fiber crystals) kuenda kunharaunda T (dense fiber crystals), nzvimbo 2 (columnar crystals) uye nharaunda 3 (recrystallization region); nekuwedzera kwesimba rekuisa ion, tembiricha yekushanduka kubva mudunhu 1 kuenda kudunhu T, dunhu 2 uye dunhu 3 inoderera. Iyo yakakwirira-density fiber makristasi uye columnar makristasi anogona kugadzirwa pakudziya kwakaderera. Kana simba remaion akaiswa rinowedzera kusvika pahurongwa hwe1-10 eV, kubhomba uye kuiswa kweiyoni panzvimbo yakavharirwa yejasi kunowedzerwa uye ukobvu hwemajasi hunowedzerwa.

No.3 Kugadzirira kweakaomesa coating layer nepamusoro simba pulsed magnetron sputtering tekinoroji

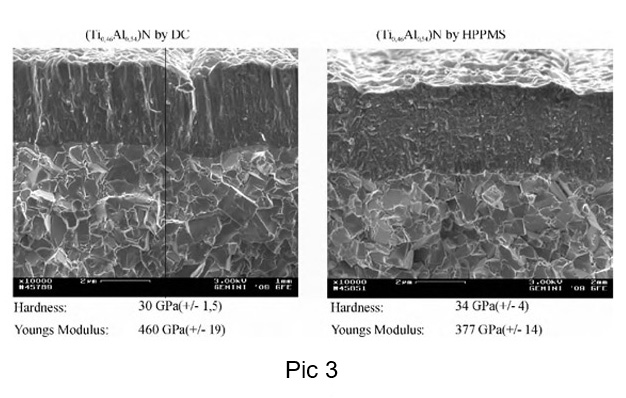

Iyo yekupfekedza inogadzirwa neakakwira simba pulsed magnetron sputtering tekinoroji yakaonda, ine zvirinani zvemuchina zvivakwa uye yakanyanya kugadzikana tembiricha. Sezvinoratidzwa muPic 3, iyo yakajairwa magnetron sputtered TiAlN coating is a columnar crystal structure ine kuoma kwe30 GPa uye Young's modulus ye460 GPa; iyo HIPMS-TiAlN coating ndeye 34 GPa kuoma uku iyo Yechidiki modulus iri 377 GPa; chiyero pakati pekuomarara neYoung's modulus chiyero chekuomarara kwejasi. Kuoma kwepamusoro uye kudiki modulus yeYoung zvinoreva kusimba kuri nani. Iyo HIPMS-TiAlN coating ine kugadzikana kwepamusoro tembiricha, ine AlN hexagonal nhanho inonaya mune yakajairwa TiAlN coating mushure mekupisa kwekushisa annealing kurapwa pa1,000 °C kwe4 h. Kuomarara kwejasi kunoderera pakupisa kwepamusoro, nepo HIPMS-TiAlN coating inoramba isina kuchinjika mushure mekupisa kupisa panguva imwechete yekupisa uye nguva. HIPMS-TiAlN coating zvakare ine yakakwirira yekutanga tembiricha yekupisa tembiricha oxidation pane yakajairwa coating. Naizvozvo, iyo HIPMS-TiAlN coating inoratidza kuita kurinani mukucheka-kumhanya maturusi kupfuura mamwe maturusi akavharidzirwa akagadzirwa nePVD maitiro.

Nguva yekutumira: Nov-08-2022