Iimpawu zePlasma

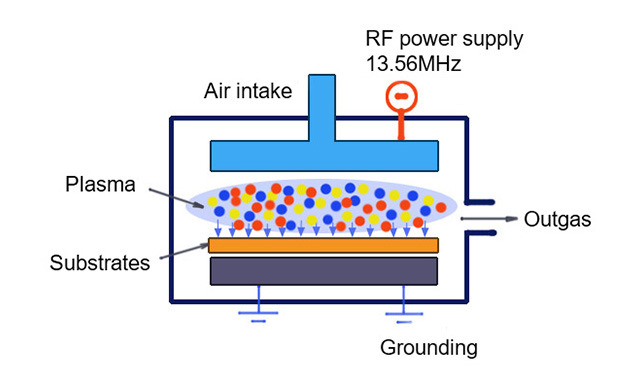

Ubume beplasma kwiplasma-ephuculweyo yokubeka umphunga wekhemikhali kukuba ixhomekeke kumandla e-kinetic yee-electron ezikwiplasma ukuze kusebenze ukusabela kweekhemikhali kwisigaba segesi. Ekubeni i-plasma yingqokelela yee-ion, ii-electron, ii-athomu ezingathathi hlangothi kunye neemolekyuli, ingathathi hlangothi ngombane kwinqanaba le-macroscopic. Kwiplasma, inani elikhulu lamandla ligcinwa kumandla angaphakathi eplasma. I-Plasma yahlulahlulwe ekuqaleni yaba yi-plasma eshushu kunye ne-plasma ebandayo. kwinkqubo ye-PECVD yiplasma ebandayo eyenziwa ngokukhutshwa kwegesi yoxinzelelo oluphantsi. Le plasma eveliswe ngokukhutshwa koxinzelelo oluphantsi ngaphantsi kwamakhulu ambalwa e-Pa yi-plasma yegesi engalinganiyo.

Ubume bale plasma buhamba ngolu hlobo lulandelayo:

(1)Intshukumo engaqhelekanga ye-thermal yee-electron kunye ne-ion idlula intshukumo yabo ethe ngqo.

(2) Inkqubo yayo ye-ionization ibangelwa ikakhulu kukungqubana kwee-electron ezikhawulezayo kunye ne-molecule yegesi.

(3) I-avareji ye-thermal yentshukumo yamandla eelektroni yi-1 ukuya kwi-2 imiyalelo yobukhulu obuphezulu kunaleyo yamasuntswana anzima, njengeemolekyuli, iiathomu, iiyoni kunye neeradicals zamahhala.

(4) Ukulahlekelwa kwamandla emva kokungqubana kwee-electron kunye namasuntswana anzima kunokuhlawulwa kwintsimi yombane phakathi kokungqubana.

Kunzima ukubonakalisa i-plasma ye-low-temperature nonequilibrium plasma enenani elincinci leeparamitha, kuba i-plasma ephantsi yobushushu obungaphantsi kwe-nonequilibrium plasma kwinkqubo ye-PECVD, apho ubushushu be-electron Te ayifani nobushushu be-Tj yamasuntswana anzima. Kwitekhnoloji ye-PECVD, umsebenzi ophambili weplasma kukuvelisa i-ion esebenzayo yeekhemikhali kunye ne-radicals yamahhala. Ezi ion kunye ne-free-radicals zisabela kunye nezinye i-ion, ii-athomu kunye ne-athomu kwisigaba segesi okanye zibangele umonakalo we-lattice kunye neekhemikhali zemichiza kwi-substrate surface, kwaye isivuno sezinto ezisebenzayo ngumsebenzi we-electron density, i-concentration reactant kunye ne-coefficient yesivuno. Ngamanye amazwi, isivuno sezinto ezisebenzayo sixhomekeke kumandla ombane ombane, uxinzelelo lwegesi, kunye ne-avareji ye-free range yamasuntswana ngexesha lokungqubana. Njengoko igesi esabelayo kwiplasma ihlukana ngenxa yokungqubana kwee-electron zamandla aphezulu, umqobo wokuvula wokusabela kweekhemikhali unokoyiswa kwaye ubushushu begesi esabelayo bunokuncitshiswa. Umahluko omkhulu phakathi kwe-PECVD kunye ne-CVD eqhelekileyo kukuba imigaqo ye-thermodynamic ye-chemical reaction yahlukile. Ukuchithwa kwee-molecule zegesi kwi-plasma akukhethi, ngoko ke ifilimu efakwe kwi-PECVD ihluke ngokupheleleyo kwi-CVD eqhelekileyo. Ukubunjwa kwesigaba esiveliswe yi-PECVD kunokuba yinto engafaniyo, kwaye ukubunjwa kwayo akusayi kukhawulelwa yi-equilibrium kinetics. Olona luhlu lwefilimu luqhelekileyo yimeko ye-amorphous.

Iimpawu zePECVD

(1) Ubushushu obuphantsi bokubekwa.

(2) Ukunciphisa uxinzelelo lwangaphakathi olubangelwa ukungahambi kakuhle kwe-coefficient yokwandisa umgca we-membrane / isiseko sezinto.

(3) Izinga lokubeka liphezulu kakhulu, ngokukodwa ukuchithwa kweqondo lokushisa eliphantsi, elilungele ukufumana iifilimu ze-amorphous kunye ne-microcrystalline.

Ngenxa yenkqubo yokushisa ephantsi ye-PECVD, umonakalo we-thermal unokuncitshiswa, ukusabalalisa okufanayo kunye nokusabela phakathi komgangatho wefilimu kunye ne-substrate material ingancitshiswa, njl., Ukuze amacandelo e-elektroniki afakwe zombini ngaphambi kokuba zenziwe okanye ngenxa yesidingo sokuphinda kusetyenzwe. Ukwenziwa kwee-ultra-large scale circuits integrated circuits (VLSI, ULSI), iteknoloji ye-PECVD isetyenziswe ngempumelelo ekubunjweni kwefilimu ye-silicon nitride (i-SiN) njengefilimu yokugqibela yokukhusela emva kokuqulunqwa kwe-Al electrode wiring, kunye nokubethelwa kunye nokwakhiwa kwefilimu ye-silicon oxide njenge-interlayer insulation. Njengezixhobo zefilimu ezincinci, iteknoloji ye-PECVD isetyenziswe ngempumelelo ekwenzeni i-transistors yefilimu encinci (i-TFTs) yemiboniso ye-LCD, njl., usebenzisa iglasi njenge-substrate kwindlela ye-matrix esebenzayo. Ngokuphuhliswa kweesekethe ezidibeneyo ukuya kwisikali esikhulu kunye nokudibanisa okuphezulu kunye nokusetyenziswa ngokubanzi kwezixhobo ze-semiconductor ezidibeneyo, i-PECVD iyadingeka ukuba yenziwe kwiqondo lokushisa eliphantsi kunye neenkqubo eziphezulu zamandla e-electron. Ukuhlangabezana nale mfuneko, ubugcisa obunokudibanisa iifilimu ezithe tyaba eziphezulu kumaqondo obushushu asezantsi kufuneka ziphuhliswe. Iifilimu ze-SiN kunye ne-SiOx ziye zafundwa ngokubanzi ngokusebenzisa i-plasma ye-ECR kunye neteknoloji entsha ye-plasma chemical vapor deposition (PCVD) ene-plasma ye-helical, kwaye ifikelele kwinqanaba elisebenzayo ekusebenziseni iifilimu ze-insulation interlayer kwiisekethe ezinkulu ezidibeneyo, njl.

Ixesha lokuposa: Nov-08-2022