KHOOM PLIG

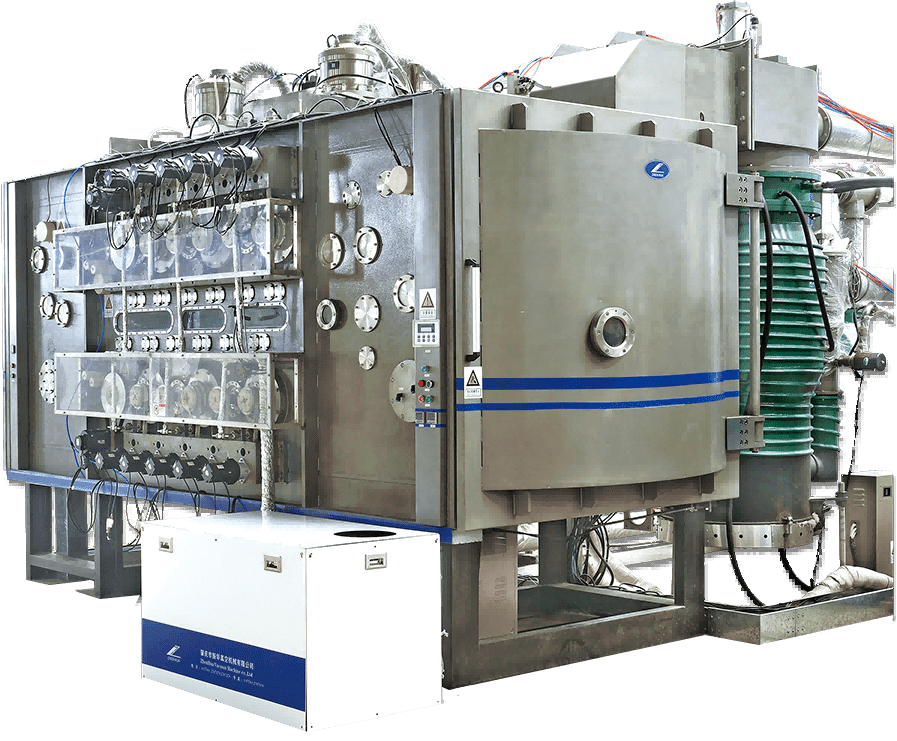

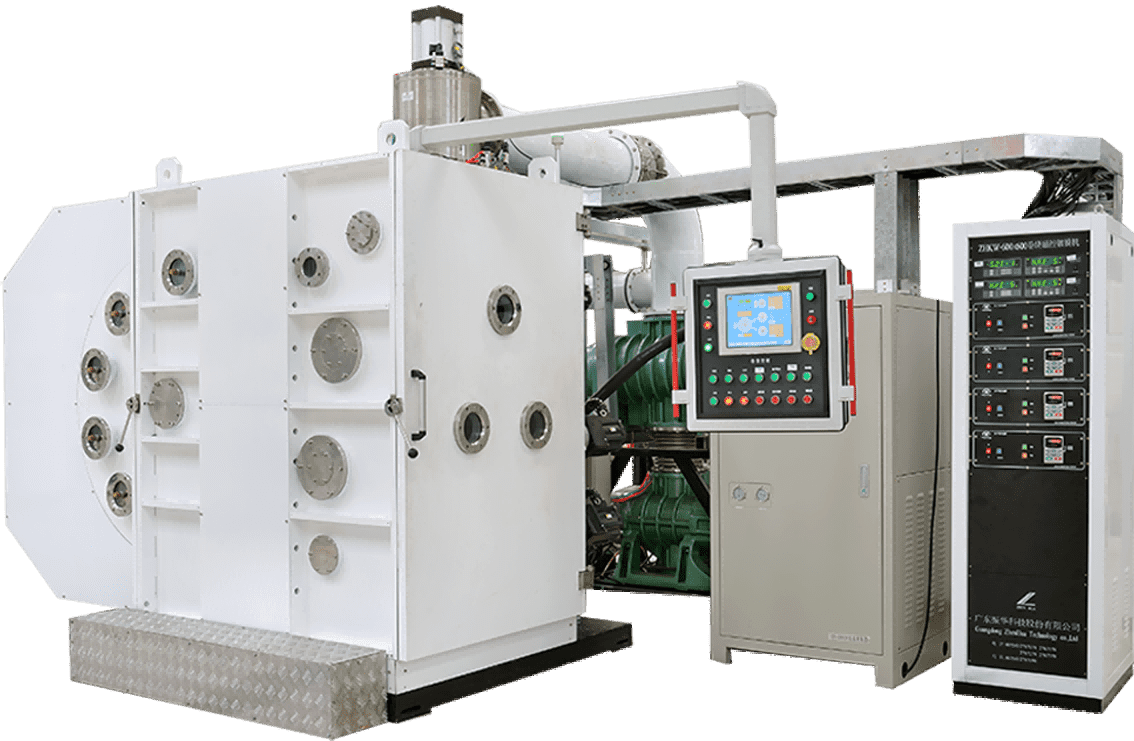

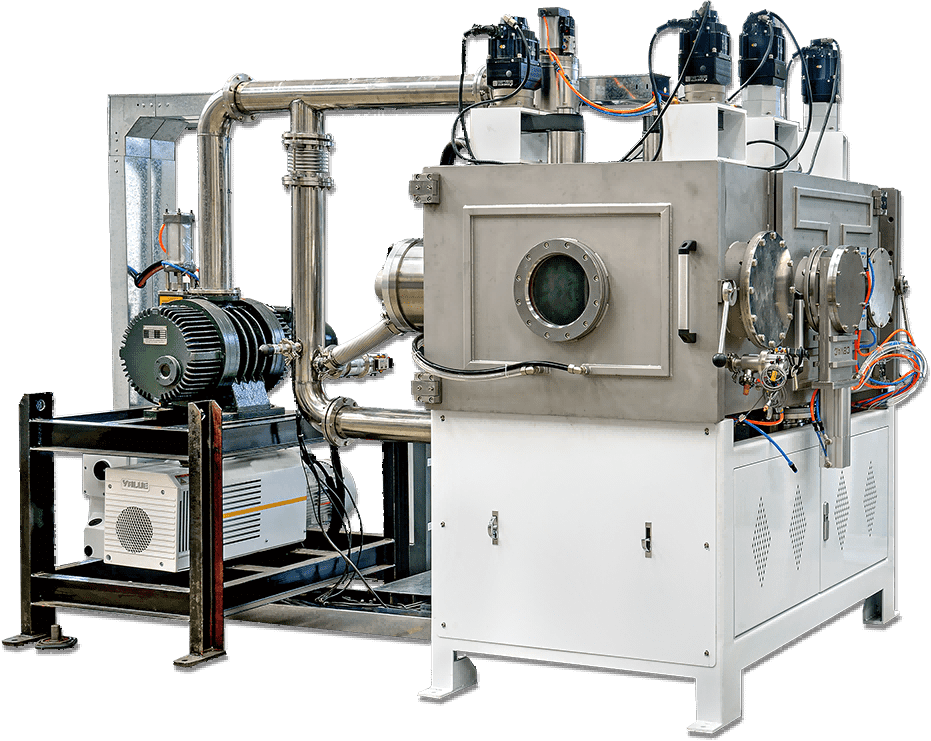

Nyob rau hauv lub tshuab nqus tsev, tso lub workpiece rau ntawm lub cathode ntawm low-pressure glow tawm thiab txhaj cov pa uas tsim nyog.Ntawm qhov kub thiab txias, txheej txheej tau txais ntawm qhov chaw ntawm lub workpiece los ntawm kev siv cov txheej txheem ionization polymerization combining tshuaj lom neeg cov tshuaj tiv thaiv thiab plasma, thaum lub gaseous tshuaj yog absorbed rau ntawm qhov chaw ntawm lub workpiece thiab reacts rau ib leeg, thiab thaum kawg yog ib tug khoom zaj duab xis. yog tsim thiab tso rau ntawm qhov chaw ntawm lub workpiece.

Yam ntxwv:

1. Tsawg kub zaj duab xis tsim, qhov kub thiab txias tsis tshua muaj kev cuam tshuam rau lub workpiece, zam lub coarse grain ntawm high-temperature film forming, thiab cov zaj duab xis txheej tsis yooj yim rau poob.

2. Nws tuaj yeem coated nrog cov zaj duab xis tuab, uas muaj qhov sib xyaw ua ke, cov nyhuv cuam tshuam zoo, compactness, me me hauv kev ntxhov siab thiab tsis yooj yim los tsim micro-tawg.

3. Cov kev ua haujlwm plasma muaj cov nyhuv tu, uas ua rau kom cov adhesion ntawm cov yeeb yaj kiab.

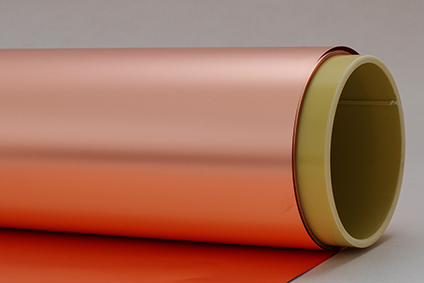

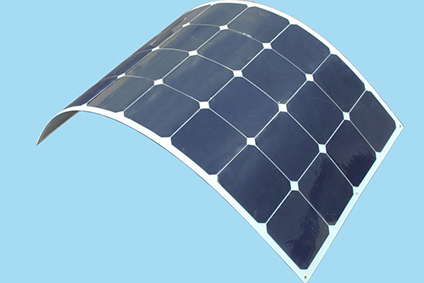

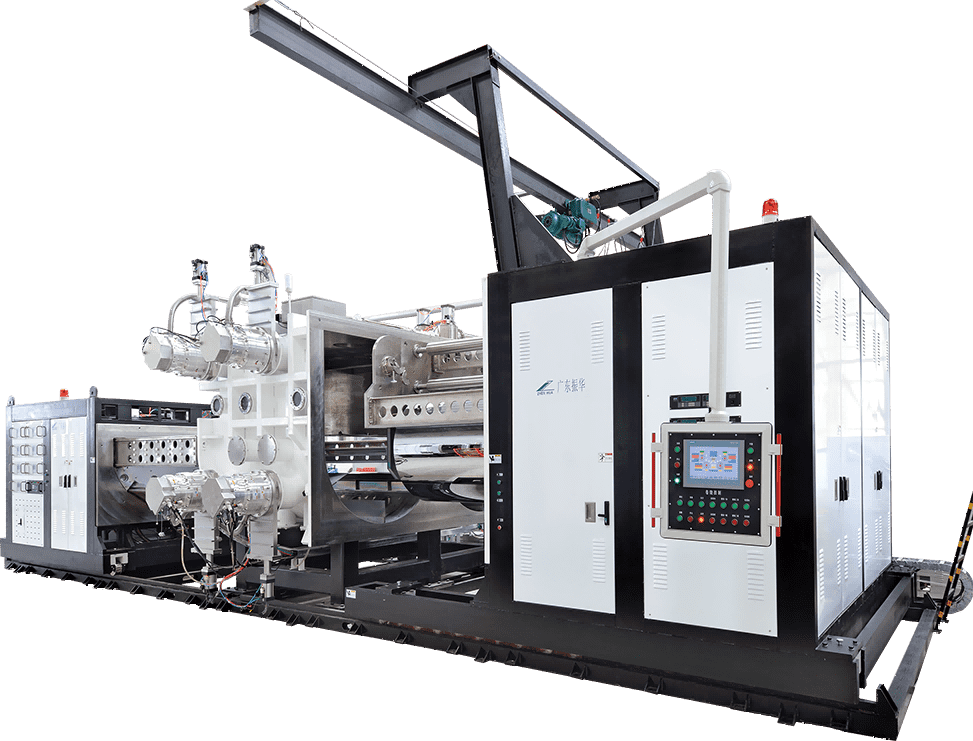

Cov cuab yeej siv tsuas yog siv rau txheej SiOx siab tiv thaiv kev tiv thaiv ntawm PET, PA, PP thiab lwm yam ntaub ntawv zaj duab xis.Nws tau dav siv hauv kev kho mob / tshuaj cov khoom ntim khoom, cov khoom siv hluav taws xob thiab cov khoom ntim khoom noj, nrog rau cov ntim ntim rau cov dej haus, cov khoom noj muaj roj thiab cov roj noj.Cov yeeb yaj kiab muaj cov khoom thaiv zoo heev, kev hloov pauv ib puag ncig, siab microwave permeability thiab pob tshab, thiab tsis cuam tshuam los ntawm ib puag ncig cov av noo thiab kub hloov pauv.Nws daws qhov teeb meem uas cov khoom ntim khoom ib txwm tuaj yeem ua rau muaj teebmeem kev noj qab haus huv.

| Cov qauv xaiv tau | Khoom loj (dav) |

| RWB 1250 | 1250 (mm) |