KHOOM PLIG

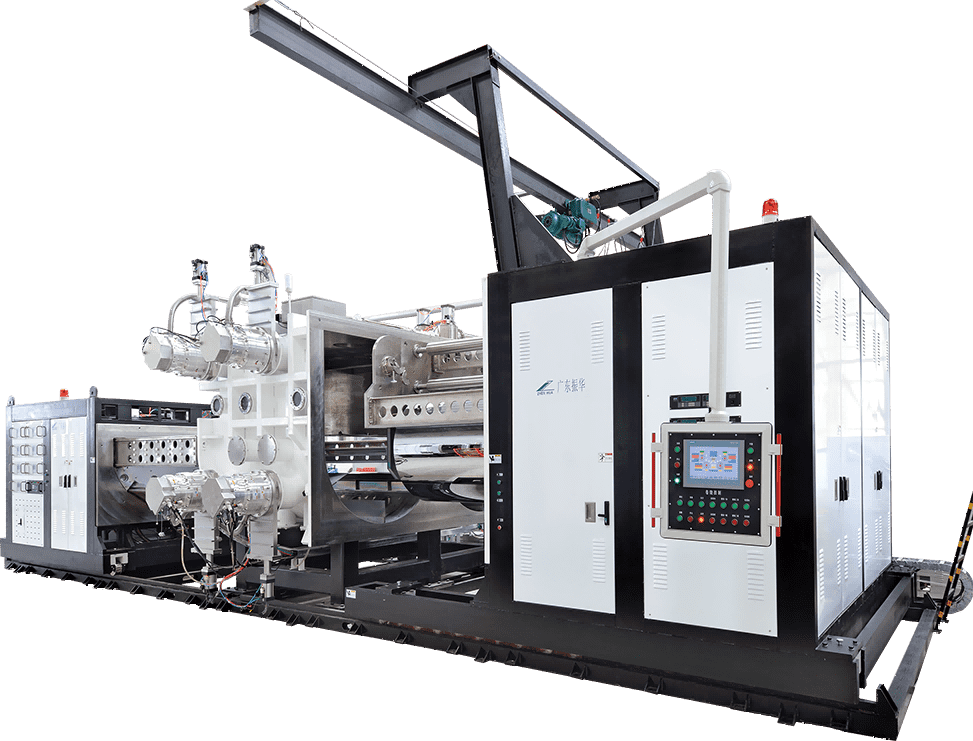

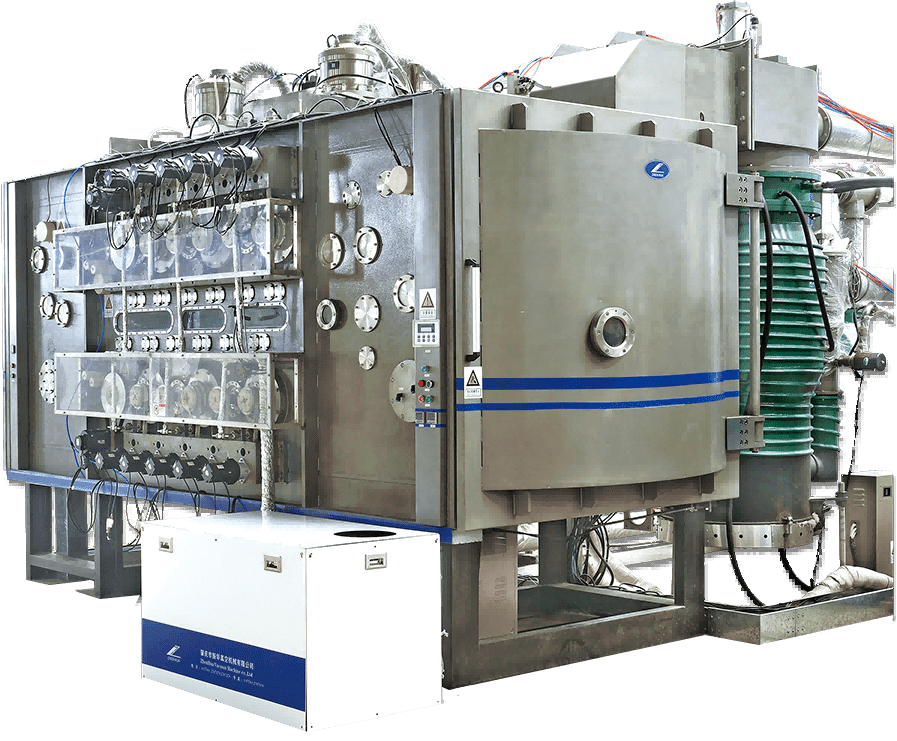

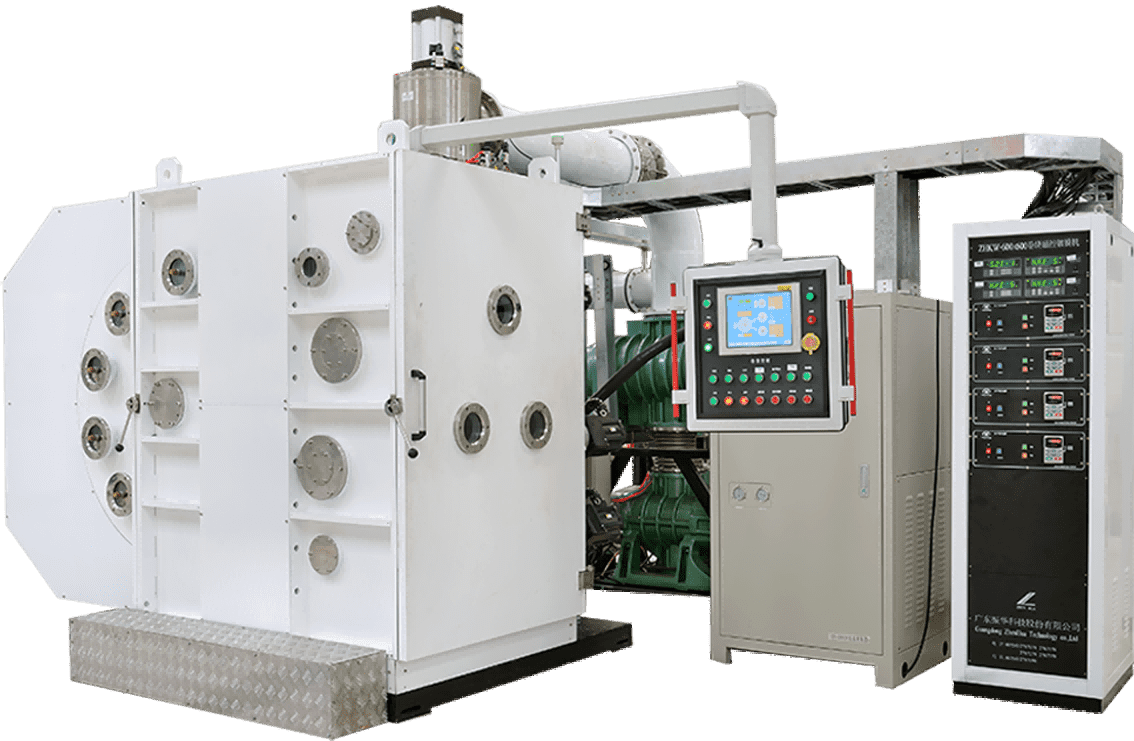

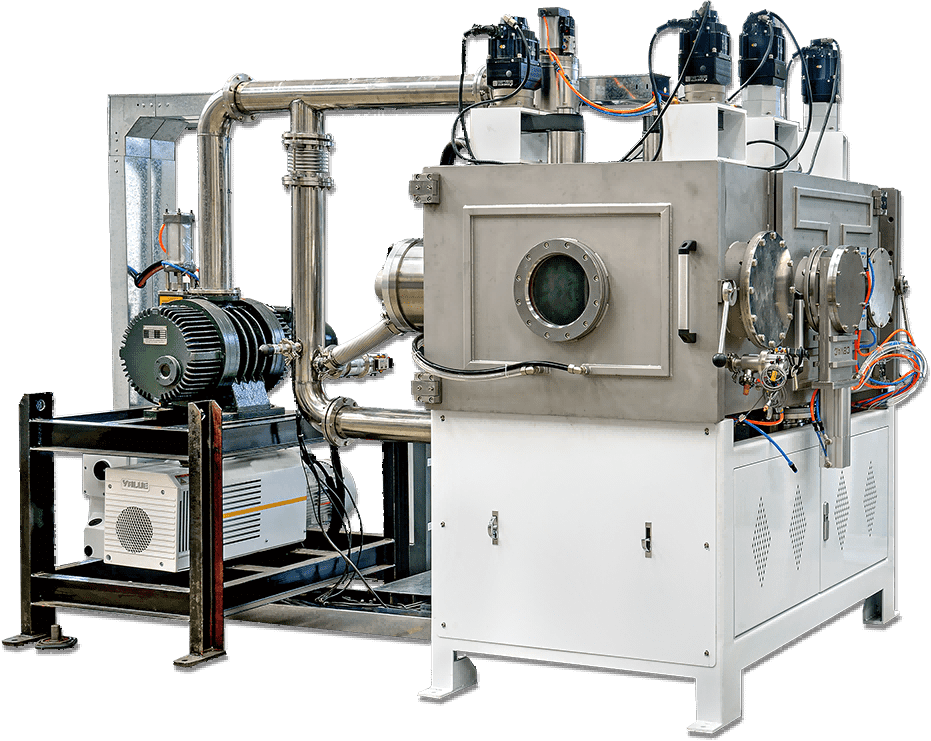

Cov khoom siv no hloov cov ntaub ntawv txheej uas tsis tshua muaj melting point thiab yooj yim rau evaporate rau hauv nano hais los ntawm cua sov nyob rau hauv nruab nrab zaus induction rauv los yog evaporation molybdenum nkoj, thiab tso lawv nyob rau saum npoo ntawm lub workpiece los tsim ib zaj duab xis.Rolled zaj duab xis yog muab tso rau hauv lub tshuab nqus tsev txheej txheej, thiab cov qauv winding yog tsav los ntawm lub cev muaj zog.Ib qho kawg tau txais zaj duab xis thiab lwm qhov muab tso rau zaj duab xis.Nws txuas ntxiv mus dhau ntawm thaj chaw evaporation kom tau txais cov txheej txheem txheej thiab tsim cov txheej txheem ntom ntom.

Khoom nta:

1. Tsawg melting point txheej khoom yog thermally evaporated nrog siab evaporation tus nqi.Lub yob zaj duab xis clings rau lub nruas txias kom sai sai tshem tawm cov evaporation cua sov.Lub yob zaj duab xis muaj me ntsis cuam tshuam rau cua sov thiab yuav tsis deform.Nws feem ntau yog siv rau txheej PET, CPP, OPP thiab lwm yam yob zaj duab xis.

2. Ntxiv qhov sib txawv, uas tuaj yeem coated nrog cov yeeb yaj kiab nrog cov khoom sib cais thiab zinc aluminium alloy films, uas yog siv rau txheej capacitor films, hluav taws xob kab zaj duab xis, thiab lwm yam.

3. Resistance evaporation molybdenum nkoj lossis nruab nrab zaus induction rauv tuaj yeem teeb tsa raws li qhov xav tau, thiab cov khoom siv txheej txheej muaj ntau yam kev siv.Cov khoom siv evaporation feem ntau suav nrog txhuas, zinc, tooj liab, tin, silicon oxide thiab zinc sulfide.

Cov khoom siv feem ntau yog siv rau txheej capacitor zaj duab xis, hluav taws xob zaj duab xis, khoom noj khoom haus thiab lwm yam khoom ntim zaj duab xis, zoo nkauj xim zaj duab xis, thiab lwm yam. Cov khoom siv siv tsib lub tshuab tsav tsheb thiab kev ceev ceev thiab kev tswj tsis tu ncua kom tsis txhob muaj wrinkle.Lub tshuab nqus tsev twj tso kua mis yog tag nrho tsis siv neeg nyob rau hauv cov txheej txheem ntawm huab cua extraction thiab zaj duab xis tshem tawm, thiab cov txheej txheem kev hloov yog yooj yim.Cov cuab yeej muaj peev xwm thauj khoom loj thiab cov yeeb yaj kiab nrawm nrawm, txog li 600m / min thiab siab dua.Nws yog cov khoom siv ntau lawm nrog lub peev xwm loj.

| Cov qauv xaiv tau | Khoom loj (dav) |

| NWS 1250 | 1250 (mm) |