KHOOM PLIG

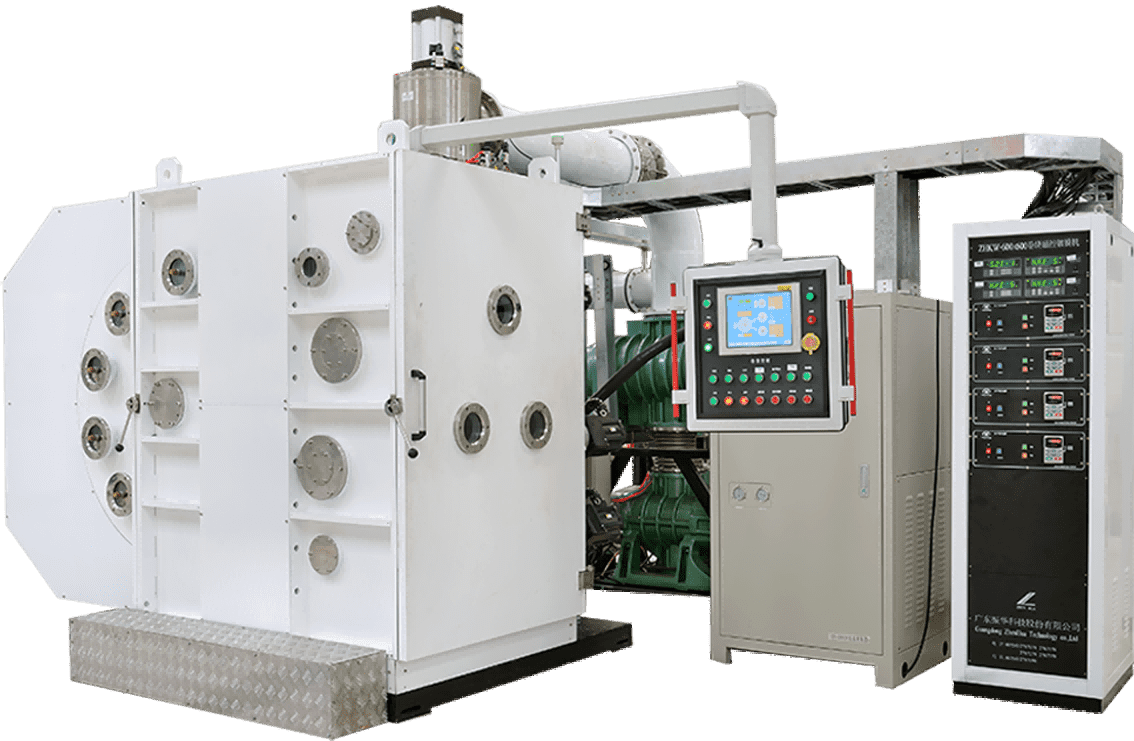

Magnetron winding txheej txheej yog siv magnetron sputtering txoj kev los hloov cov khoom txheej rau hauv gaseous los yog ionic lub xeev nyob rau hauv lub tshuab nqus tsev ib puag ncig, thiab ces tso rau ntawm lub workpiece los ua ib tug tuab zaj duab xis.Yog li txhawm rau txhim kho lub xeev saum npoo av lossis tau txais qee qhov kev ua haujlwm tshwj xeeb ntawm kev ua haujlwm lossis cov yeeb yaj kiab zoo nkauj.

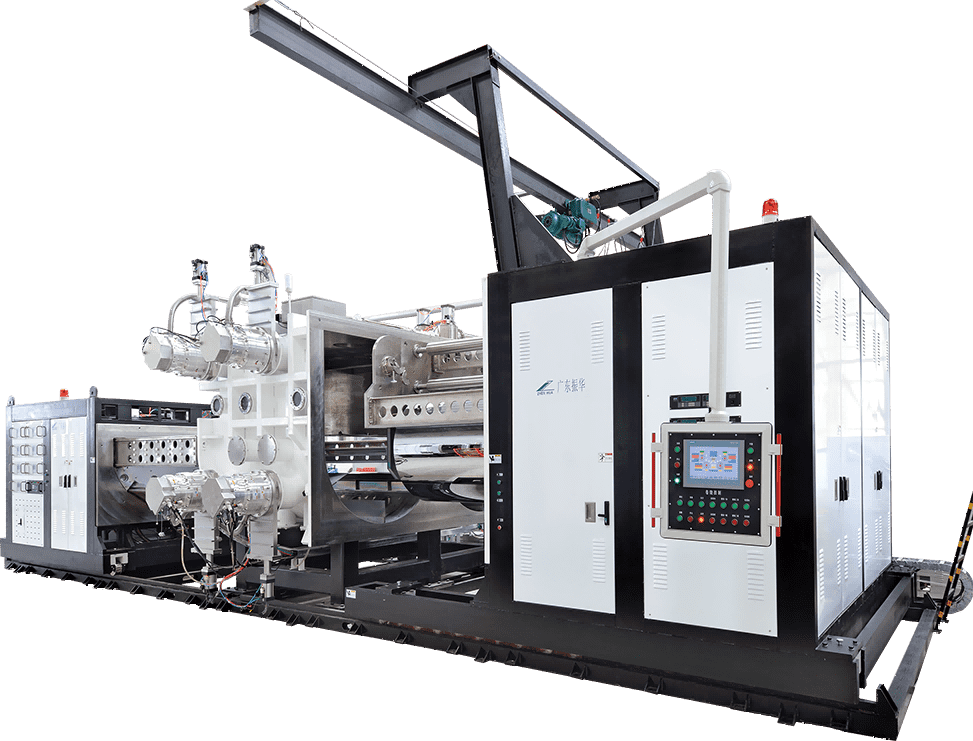

Cov cuab yeej siv magnetron sputtering system thiab precision winding tswj qhov system, thiab yog nruab nrog servo lub cev muaj zog tsav tswj qhov system kom paub qhov nro tas li thiab tswj ceev tsis tu ncua.

1. Nruab nrog tsis siv neeg zaj duab xis flattening system, zaj duab xis tsis wrinkled, thiab winding zoo yog siab.

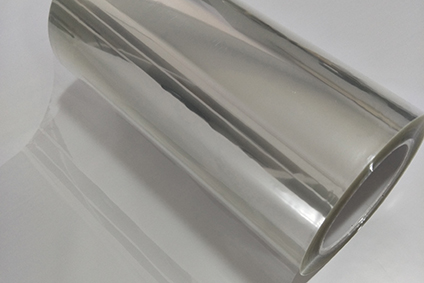

2. Lub kaw-loop tswj system yog ntxiv los txhim kho tus nqi deposition.Multilayer dielectric zaj duab xis tuaj yeem txuas ntxiv coated ntawm PET coil nrog qhov dav ntawm 1100mm, nrog kev rov ua haujlwm zoo thiab cov txheej txheem ruaj khov.

3. Lub tshuab winding thiab lub hom phiaj tuaj yeem rub tawm los ntawm ob qho kawg raws li los pab txhawb kev thauj khoom thiab tshem tawm ntawm daim nyias nyias yob thiab hloov lub hom phiaj tu.

Cov cuab yeej muaj qib siab ntawm automation, cia li saib xyuas lub xeev ua haujlwm ntawm cov khoom siv, thiab muaj lub luag haujlwm ntawm lub tswb tsis zoo thiab tsis siv neeg tiv thaiv.Cov cuab yeej ua haujlwm tsis tshua muaj teeb meem.

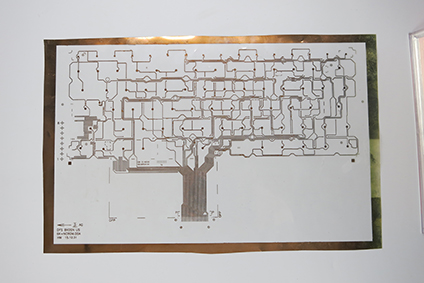

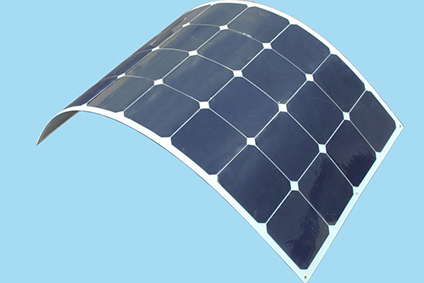

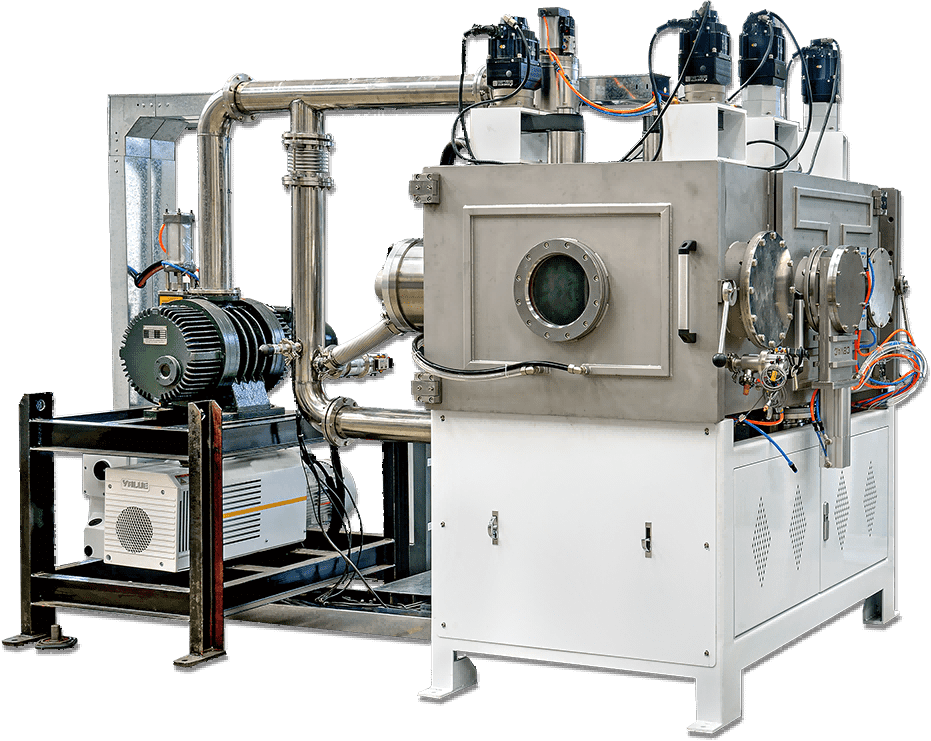

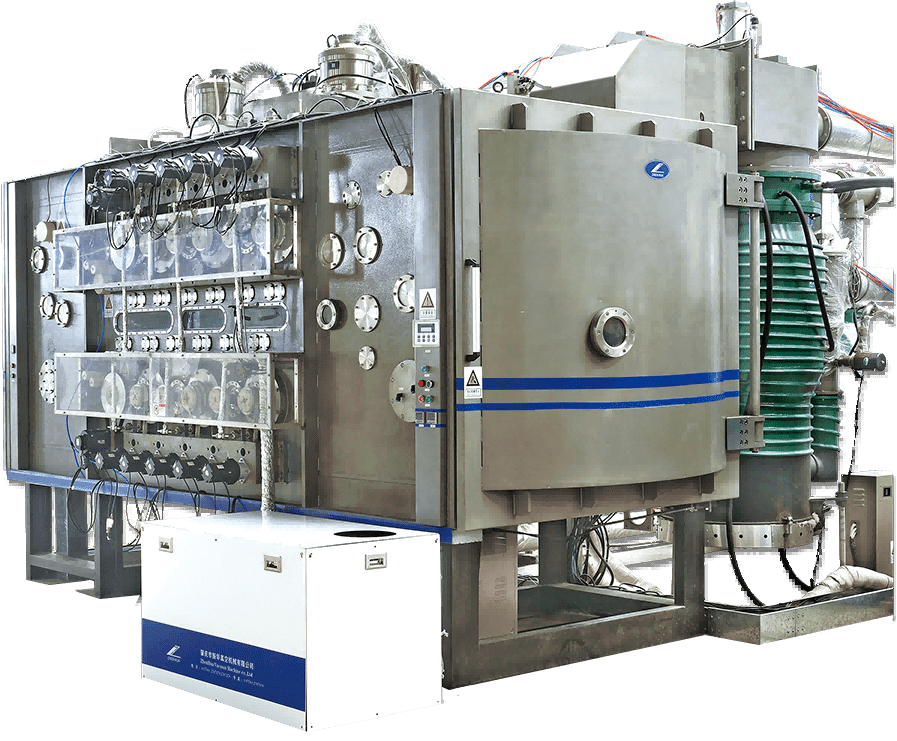

Cov cuab yeej tuaj yeem tso Nb2O5, TiO2, SiO2 thiab lwm yam oxides, Cu, Al, Cr, Ti thiab lwm yam hlau yooj yim, uas yog siv rau kev tso nyiaj ntau txheej optical xim thiab cov yeeb yaj kiab hlau yooj yim.Cov khoom siv yog tsim rau PET zaj duab xis, daim ntaub conductive thiab lwm yam ntaub ntawv hloov tau yooj yim, thiab yog dav siv hauv xov tooj ntawm tes zoo nkauj zaj duab xis, ntim zaj duab xis, EMI electromagnetic shielding zaj duab xis, ITO pob tshab zaj duab xis thiab lwm yam khoom.

| Cov qauv xaiv tau | Khoom loj (dav) |

| RCX1100 Nws | 1100 (mm) |