Rea u amohela ho Guangdong Zhenhua Technology Co.,Ltd.

Litaba

-

Cylindrical magnetron sputtering: tsoelo-pele ea ho kenya filimi e tšesaane

Lefapheng la theknoloji e tšesaane ea ho beha lifilimi, cylindrical magnetron sputtering e se e le mokhoa o sebetsang hantle le o fapaneng. Theknoloji ena e ncha e fa bafuputsi le litsebi tsa indasteri mokhoa oa ho beha lifilimi tse tšesaane ka ho nepahala le ho tšoana ho ikhethang. Cylindrical magnetron s...Bala haholoanyane -

Mochini oa ho roala ka 'mala oa khauta oa vacumm

Mechini ea ho fafatsa khauta e fetohile theknoloji e etellang pele, e fetolang tsela eo re sebelisang lesela le lesesaane la khauta libakeng tse fapaneng. Ka ts'ebetso ea bona e ikhethang le ho nepahala ho ikhethang, metjhini ena e fetohile batho ba fetolang lipapali liindastering ho tloha ho tsa elektroniki ho isa ho tsa optics. Karolong ena ea bonono ...Bala haholoanyane -

Mochini oa ho roala oa mini pvd

Lilemong tsa morao tjena, indasteri ea phekolo ea holim'a metsi e entse tsoelo-pele e kholo ka lebaka la ho hlahisoa ha mechine e nyenyane ea PVD. Theknoloji ena e ncha e fetola tsela eo marulelo a ntlafatsoang ka eona, e fana ka katleho e ke keng ea lekanngoa le ho nepahala. Ka poso ena ea blog, re tla tšohla ka ...Bala haholoanyane -

Baetsi ba mechine ea Optical

Ha thekenoloji e ntse e tsoela pele ka lebelo le neng le e-s'o ka le e-ba teng, indasteri ea optical e bone phetoho e tsotehang, ka lebaka la mekhoa e mecha le katleho e hlahisitsoeng ke baetsi ba pele ba mechine ea optical. Likhamphani tsena, tse nang le mahlale a morao-rao le boitlamo ba ...Bala haholoanyane -

Mochini oa ho roala oa ion oa mofuta oa coaxial electromagnetic field

1. Mochini oa ho roala li-ion tsa cathode le mochine o chesang oa wire arc ion Sethunya se sekoti sa cathode le sethunya sa arc se chesang se kenngoe ka holim'a kamore ea ho roala, anode e kenngoa ka tlase, 'me li-coil tse peli tsa motlakase li kenngoa ka holimo le ka tlaase ho kamoreng ea ho roala ...Bala haholoanyane -

ion beam sputtering coat le ion beam etching

1. Ion beam sputtering coating Bokaholimo ba thepa bo hlasetsoe ka ion ea matla a mahareng, 'me matla a li-ion ha a kene ka lesela la kristale la lintho tse bonahalang, empa a fetisetsa matla ho liathomo tse lebisitsoeng, li etsa hore li phatlohe hole le holim'a thepa, ebe ...Bala haholoanyane -

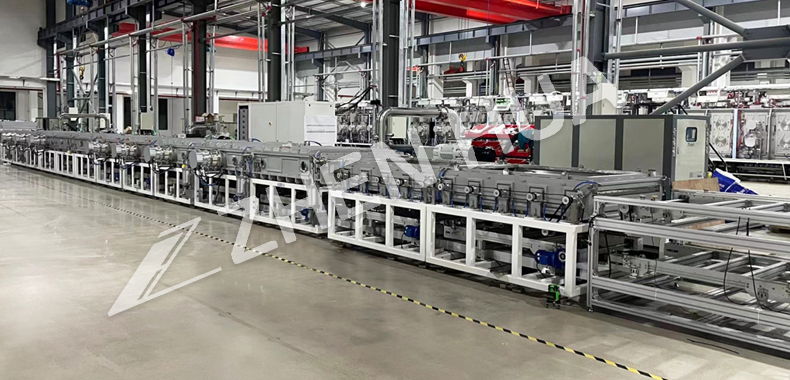

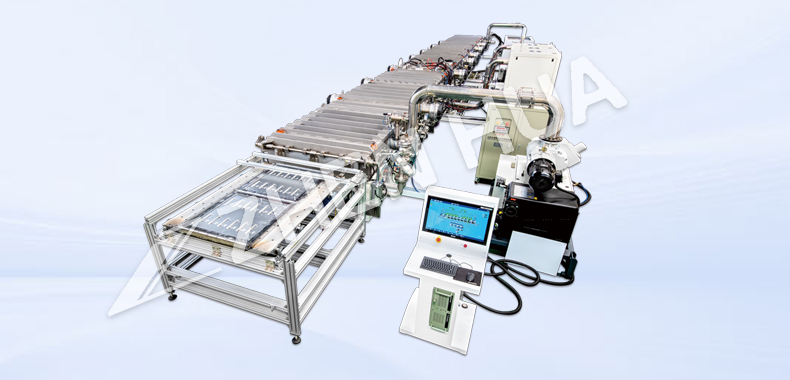

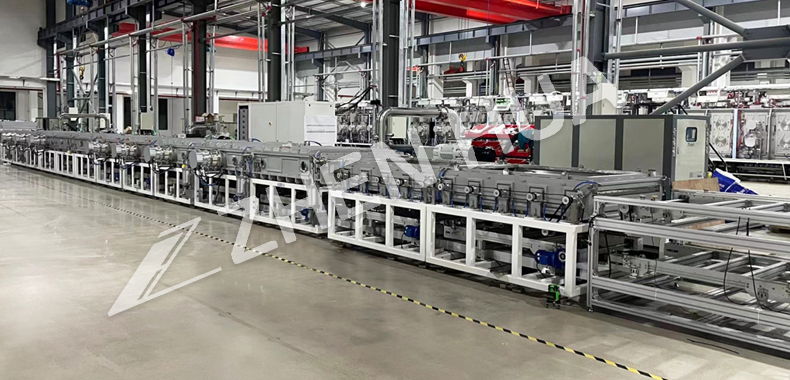

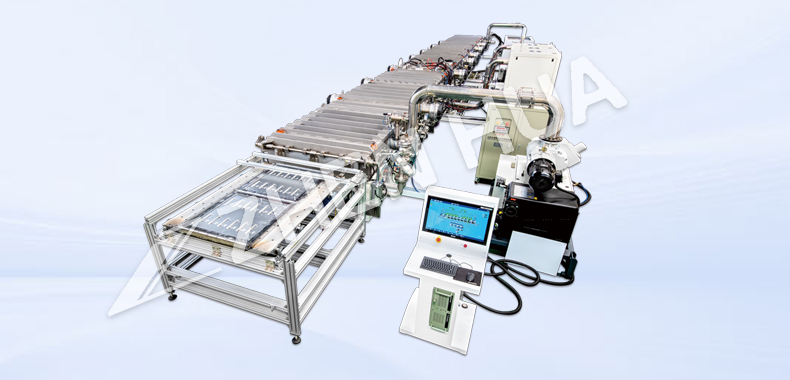

Mochini oa ho roala oa Magnetron sputtering vacuum coating

Lefapheng la theknoloji e tsoetseng pele ea ho roala holim'a metsi, lebitso le le leng le hlahella - magnetron sputtering vacuum coating machine. Thepa ena e tsoetseng pele e etsa maqhubu ho pholletsa le indasteri ka ho fana ka litharollo tse tšepahalang, tse sebetsang hantle tsa ho roala holim'a metsi. Ho tloha ho lisebelisoa tsa elektroniki ho isa likoloing, ho tloha ho aerospace...Bala haholoanyane -

Mochini oa ho roala filimi oa composite optical

Lilemong tsa morao tjena, lifilimi tse kopaneng tsa optical li atile haholo ka lebaka la thepa ea tsona e khahlang le ts'ebeliso ea tsona liindastering tse fapaneng. E 'ngoe ea lintlha tse ka sehloohong tse tlatsetsang boleng bo phahameng ba filimi ena ke mokhoa o tsoetseng pele oa ho roala o sebelisoang ho e bopa. Kajeno re tla bua ka ...Bala haholoanyane -

Theknoloji ea ho roala ka Calcitonite Solar Cells

Ka 2009, ha lisele tse tšesaane tsa filimi ea calcite li qala ho hlaha, katleho ea phetoho e ne e le 3.8% feela, 'me e eketsehile ka potlako, Unit 2018, katleho ea laboratori e fetile 23%. Mokhoa oa motheo oa molek'hule oa motsoako oa chalcogenide ke ABX3, 'me boemo ba A hangata ke ion ea tšepe, e kang Cs + ...Bala haholoanyane -

Metal Organic Chemical Vapor Deposition

Metal organic chemical vapor deposition (MOCVD), mohloli oa lintho tse nang le khase ke metal organic compound gase, 'me mokhoa oa motheo oa ho etsa deposition o tšoana le CVD. 1.MOCVD khase e tala Mohloli oa khase o sebelisoang bakeng sa MOCVD ke metal-organic compound (MOC) gas. Metal-organic compounds e tsitsitse...Bala haholoanyane -

Mochini oa ho roala ka vacuum aluminium metallizing

Vacuum Aluminium Metal Coater, eo ka tloaelo e tsejoang e le VAMCM, ke theknoloji e tsoetseng pele e sebelisang mokhoa o khethehileng oa vacuum ho kenya lesela le tšesaane la aluminium linthong tse fapaneng. Ho nepahala le ho nepahala ho ikhethang ha mochini ho etsa bonnete ba hore liaparo tsa tšepe tse ts'oanang li khomarela phephetso e kholo ka ho fetisisa ...Bala haholoanyane -

Ho hlahisa mochini oa ho roala ka vacuum metalizing: ho fetola indasteri ea ho roala

Lilemong tsa morao tjena, indasteri ea ho roala e bone tsoelo-pele e tsotehang ka ho kenngoa ha mechine ea ho roala ka vacuum metalizing. Mechini ena e tsoetseng pele e fetotse tsela eo liphaephe li sebelisoang ka eona libakeng tse fapaneng, e fana ka sephetho se setle le ho tšoarella joalo ka ha ho mohla ...Bala haholoanyane -

Lisebelisoa tsa daemane joalo ka lifilimi tsa carbon

(1) ho itšeha sesebelisoa tšimo DLC filimi sebelisoa e le sesebelisoa (tse kang drill, milling cutters, carbide inserts, joalo-joalo) barbotage, ka ntlafatsa bophelo ba sesebelisoa le bohale ba sesebelisoa bohale, fokotsa sharpening nako, empa hape o na le tlaase haholo khohlano factor, tlaase adhesion le e babatsehang ea ho apara ho hanyetsa. Ka hona, lisebelisoa tsa lifilimi tsa DLC sho ...Bala haholoanyane -

Theknoloji ea ho roala liseleng tsa letsatsi tsa CdTe

Lisele tsa letsatsi tse tšesaane esale e le setsi sa lipatlisiso tsa indasteri, ts'ebetso e 'maloa ea phetoho e ka fihla ho feta 20% ea theknoloji ea betri ea lifilimi tse tšesaane, ho kenyeletsoa betri ea cadmium telluride (CdTe) le copper indium gallium selenide (CICS, Cu, In, Ga, Se abbreviation) ...Bala haholoanyane -

Lifilimi tse tšesaane tsa Optical ka lihlahisoa tse bonts'ang

Hoo e ka bang lifilimi tsohle tse tloaelehileng tsa optical li sebelisoa mekhoeng ea ho bonts'a kristale ea metsi. Sistimi e tloaelehileng ea LCD e bonts'a optical e na le mohloli o bobebe (lebone la tšepe la halide kapa lebone la khatello e phahameng ea mercury), sistimi e khanyang ea leseli (ho kenyeletsoa le sistimi e khanyang le phetoho ea polarization ...Bala haholoanyane