Ku soo dhawoow Guangdong Zhenhua Technology Co., Ltd.

Wararka

-

Birta Ka-hortagga Farta-Fingerprint Vakuum Coaters

Isticmaalka mishiinada dahaadhka faakuumka ee faraha ka-hortagga biraha waxay ka dhigan tahay horumar wayn oo laga sameeyay tignoolajiyada ilaalinta dusha sare. Marka la isku daro tignoolajiyada faakuumka iyo dahaarka khaaska ah, mashiinadani waxay abuuraan lakab khafiif ah oo xidhashada u adkaysta meelaha birta ah ee ka ilaalinaya faraha iyo kuwa kale...Sii akhri -

Mashiinka Dahaarka faaruqinta Waxtarka leh

Dhinacyada wax soo saarka horumarsan iyo wax soo saarka warshadaha, baahida loo qabo mashiinnada dahaarka faakuumka ayaa sii kordhaya. Mashiinadan casriga ah ayaa wax ka beddelaya habka loo dahaadhay agabka kala duwan, iyaga oo keenaya adkeysiga, waxqabadka iyo bilicda. Boloogan po...Sii akhri -

Mabda'a Xulashada Qalabka Yoolka iyo Kala Soocida

Iyada oo ay sii kordheyso horumarinta tikniyoolajiyada daahan daahan, gaar ahaan magnetron sputtering technology, hadda, wax kasta oo wax lagu diyaarin karaa by filimka bartilmaameedka bombardment, maxaa yeelay, bartilmaameedka waxaa sputtered in geeddi-socodka lagu dahaadhay in nooc ka mid ah substrate, tayada ...Sii akhri -

Dahaarka Dahaarka RF Astaamaha ugu Muhiimsan

A. Heerka candhuufta sare. Tusaale ahaan, marka la dhufto SiO2, heerka dhigista wuxuu noqon karaa ilaa 200nm/min, badiyaa ilaa 10 ~ 100nm/daqiiqo. Iyo heerka samaynta filimku wuxuu si toos ah u dhigmaa awoodda soo noqnoqda ee sarreeya. B. Isku-xidhka u dhexeeya filimka iyo substrate-ka ayaa ka weyn vacuum vap-kaSii akhri -

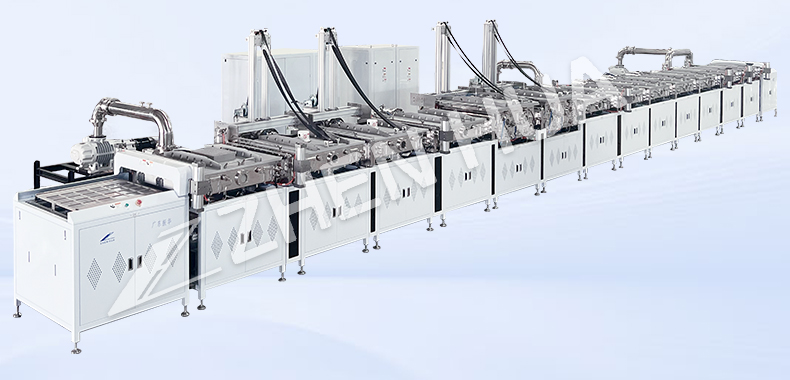

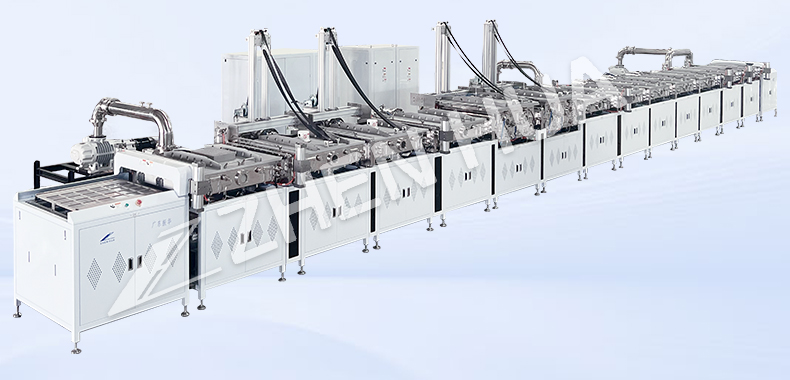

Khadadka Dahaarka Soo saarista Filimka Gaariga

Khadadka wax soo saarka filimka nalalka baabuurta ayaa ah qayb muhiim ah oo ka mid ah warshadaha wax soo saarka baabuurta. Khadadkan wax-soo-saarka ayaa mas'uul ka ah daaha iyo soo saarista filimada laambada baabuurta, kuwaas oo door muhiim ah ka ciyaara kor u qaadista bilicda iyo shaqeynta nalalka baabuurta. Sida baahida loo qabo tayada sare...Sii akhri -

Doorka Goobta Birlabka ee Magnetron Sputtering

Kala-soocidda Magnetron inta badan waxaa ka mid ah gaadiidka balaasmaha ee dheecaanka ah, etching bartilmaameedka, dhigista filimka khafiifka ah iyo hababka kale, goobta magnetic ee habka xajinta magnetron waxay yeelan doontaa saameyn. Nidaamka sputtering magnetron iyo goobta magnetic orthogonal, electrons waxay ku xiran yihiin th ...Sii akhri -

Shuruudaha Mashiinka Dahaarka Fakuumka ee Nidaamka Tuujinta

Mashiinka dahaarka Vacuum ee nidaamka bamgareynta ayaa leh shuruudaha aasaasiga ah ee soo socda: (1) Nidaamka faakuumka dahaarka waa inuu lahaadaa heer bamgareyn ku filan oo weyn, kaas oo aan kaliya si degdeg ah u soo saarin gaasaska laga sii daayo substrate-ka iyo walxaha la uumimay iyo qaybaha ku jira vacuum ch ...Sii akhri -

Mashiinka Dahaarka ee PVD dahabka ah

Mashiinka daahan dahabka ah ee PVD wuxuu adeegsadaa habka loo yaqaan Dhigista Uumiga Jirka (PVD) si loo mariyo daahan khafiif ah laakiin waara oo lagu dhejiyo qaybaha dahabka. Habkani wuxuu ku lug leeyahay isticmaalka nadiifinta sare, bartilmaameedyada birta ah ee adag, kuwaas oo uumi-baxsan yahay jawi faaruq ah. Uumiga birta ah ee ka dhashay markaas ayaa koobi kara...Sii akhri -

Mashiinka Dahaarka Vacuum Yar ee Dabacsan

Mid ka mid ah faa'iidooyinka ugu muhiimsan ee mashiinnada daahan vacuum PVD yar dabacsan waa kala duwanaanshahooda. Mashiinadan waxaa loogu talagalay in lagu daboolo cabbirro iyo qaabab kala duwan oo substrate ah, taas oo ka dhigaysa mid ku habboon hababka wax soo saarka ee cabbirka yar ama caadiga ah. Intaa waxaa dheer, cabbirkeeda is haysta iyo confi dabacsanSii akhri -

Qalabka Goynta Mashiinka Dahaarka Fakiyuumka

Warshadaha wax soo saarka ee soo koraya, qalabka goynta ayaa door muhiim ah ka ciyaara qaabeynta alaabada aan isticmaalno maalin kasta. Laga soo bilaabo goynta saxda ah ee warshadaha hawada hawada ilaa naqshadaha adag ee goobta caafimaadka, baahida loo qabo qalab goynta tayada sare leh ayaa sii socota. Si loo daboolo baahidan, anaga...Sii akhri -

Saamaynta bamka ion ee lakabka filimka / interface substrate

Marka ay bilaabato dhigista atamka xuubabka, ion bombardment waxay leedahay saamaynta soo socota ee xuubka / substrate interface. (1) Isku dhafka jirka. Sababtoo ah duritaan tamar sare leh, atamyada kaydsan iyo duritaanka soo noqnoqda ee atamka dusha sare iyo ifafaalaha shilalka cascade, iyo...Sii akhri -

Soo noolaynta iyo Horumarinta Dahaarka Vacuum sputtering

Tuurtu waa dhacdo ay qaybaha tamarta (sida caadiga ah ions of gases) ku dhuftaan dusha adag (hoos loo yaqaan walxaha la beegsanayo), taasoo keenaysa atamka (ama molecules) oogada walaxda la beegsanayo inay ka baxsadaan. Dhacdadan waxa daaha ka qaaday Grove 1842 markaas oo...Sii akhri -

Astaamaha daahan magnetron sputtering cutubka 2

Astaamaha dahaarka xajinta magnetron (3) tamar hoose Sababtoo ah korantada cathode-ka hooseeya ee lagu dabaqo bartilmaameedka, balaasmadu waxay ku xiran tahay goobta magnetic ee booska u dhow cathode, sidaas darteed waxay joojinaysaa qaybaha tamarta sare ee dhinaca dhinaca substrate-ka ee dadku toogtay. The...Sii akhri -

Astaamaha dahaarka xajinta magnetron cutubka 1

Marka la barbar dhigo tikniyoolajiyadda dahaarka kale, daahan magnetron sputtering waxaa lagu gartaa sifooyinka soo socda: xuduudaha shaqada leeyihiin kala duwanaansho firfircoon oo kala duwan ee xawaaraha dhigaalka daahan iyo dhumucdiisuna waxay noqon kartaa si fudud loo xakameeyo, oo ma jiro design ...Sii akhri -

Ion beam waxay caawisay tignoolajiyada meel dhigista

Tignoolajiyada meel dhigista ee la kaalmaynayey ion beam waa duritaanka ion beam iyo tignoolajiyada daahan uumiga dhigaalka oo ay weheliso tignoolajiyada farsamaynta ee dusha sare ee ion. Inta lagu jiro habka wax ka beddelka dusha sare ee alaabta ion ee la isku duray, ha ahaato agabka semiconductor ama agabka injineernimada, waa...Sii akhri