Welcome to Guangdong Zhenhua Technology Co.,Ltd.

Industry News

-

Ceramic Floor Tiles sputtering vacuum coating machine

The sputtering vacuum coating machine utilizes advanced technology to apply thin film coatings to ceramic floor tiles. This process involves the use of a vacuum chamber to deposit metallic or compound coatings onto the surface of the tiles, resulting in a durable and aesthetically pleasing finish...Read more -

Auto Parts Metallizing Vacuum Coating Machine

One of the key factors driving this trend is the growing awareness of the importance of using high-quality coatings on auto parts. These coatings not only enhance the aesthetics of the parts but also provide protection against corrosion and wear, ultimately extending the lifespan of the auto part...Read more -

Glass Ceramic Tiles Gold Plating Machine

The glass ceramic tiles gold plating machine utilizes advanced techniques to apply a thin layer of gold plating onto the surface of the tiles, creating a stunning and luxurious appearance. This process not only enhances the aesthetic appeal of the tiles but also provides added protection against ...Read more -

Principles of substrates and film selection

During the film preparation process, the substrate can be selected according to the following force surface: 1. According to different application purposes, select Gold Show or Alloy, Glass, Ceramics and Plastic as a substrate; 2. The structure of the substrate material is corresponding to the fi...Read more -

The surface shape and thermal expansion coefficient of the substrate on the film

Facing the growth of the film has a very important impact. If the surface roughness of the substrate is large, and more and more combined with surface defects, it will affect the attachment and growth rate of the film. Therefore, before the vacuum coating starts, the substrate will be pre -proces...Read more -

Resistance heating evaporation source characteristics, requirements and material selection

Resistance heating evaporation source structure is simple, easy to use, easy to make, is the most widely used one kind of evaporation source. People are usually called heat generator or evaporation boat. Heating the requirements of the resistance material used is: high temperature, resistivity, ...Read more -

Evaporation source design and use of the problem

In the process of vacuum evaporation and vacuum ion, the membrane material will be in 1000 ~ 2000C high temperature, so that its Yanfa vaporization of the device, known as the evaporation source. Evaporation source more types, garlic hair source vaporization of membrane materials are different pr...Read more -

Plastic Spoon Pvd Vacuum Coating Machine

PVD (Physical Vapor Deposition) vacuum coating is a process that uses a vacuum chamber to deposit thin films of material onto a substrate. This technology has been widely used in manufacturing to enhance the performance and appearance of various products, and is now also being applied to the prod...Read more -

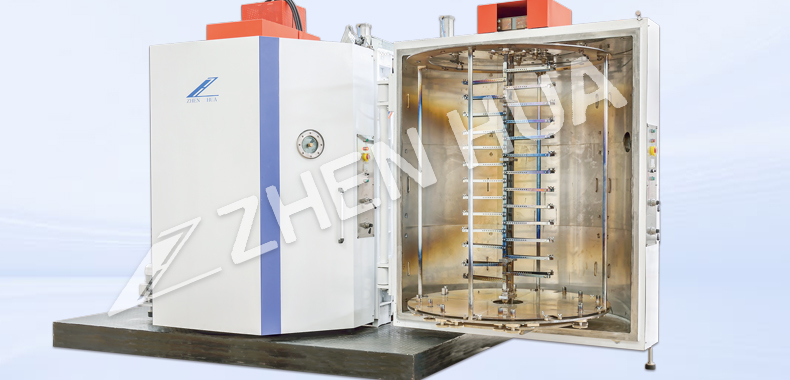

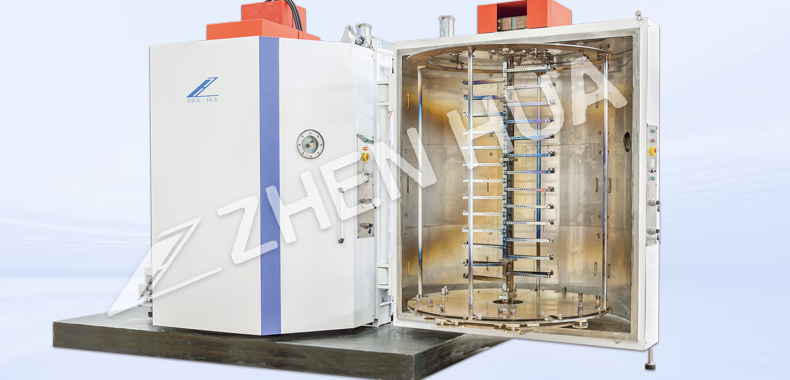

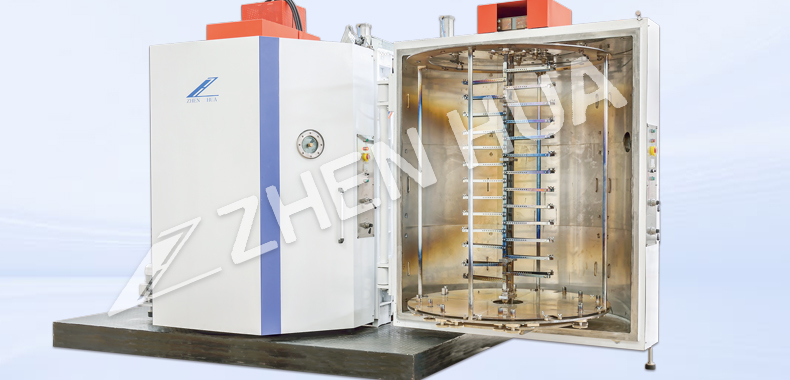

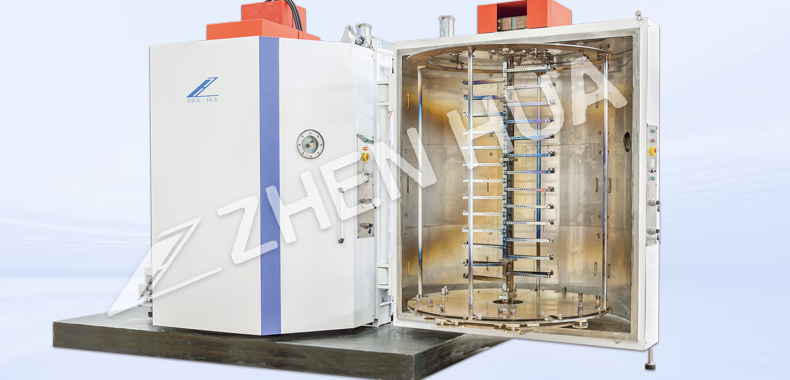

Multifunctional Vacuum Coating Equipment

The multifunctional vacuum coating equipment utilizes state-of-the-art technology to apply thin coatings to various materials, including metals, glass, and plastics. This process not only enhances the aesthetics of the products but also improves their durability and performance. As a result, manu...Read more -

Sanitaryware Pvd Vacuum Coating Equipment

Sanitaryware PVD Vacuum Coating Equipment is a game-changer in the production of sanitaryware products. This advanced technology utilizes a process called Physical Vapor Deposition (PVD) to create a durable and long-lasting coating on sanitaryware products. The result is a high-quality finish tha...Read more -

Precision Vacuum Coating Equipment

Precision vacuum coating equipment refers to special machinery that applies thin films and coatings to various materials with extremely high precision. The process takes place in a vacuum environment, which eliminates impurities and results in superior uniformity and consistency in coating applic...Read more -

Large Horizontal Vacuum Coating Equipment

One of the key benefits of large horizontal vacuum coating equipment is its ability to apply thin, uniform coatings to large, flat substrates. This is particularly important in industries such as glass manufacturing, where achieving consistent coating thickness across a large surface area is esse...Read more -

Watch Ion Gold Vacuum Coating Machine

The working principle of the watch ion gold vacuum coating machine is to use the physical vapor deposition (PVD) process to plate a thin layer of gold on the surface of watch parts. The process involves heating the gold in a vacuum chamber, causing it to evaporate and then condense on the surface...Read more -

Nano Ceramic Vacuum Coating Machine

Nano ceramic vacuum coating machine is a state-of-the-art technology that uses a vacuum deposition process to coat thin layers of ceramic materials onto various substrates. This advanced coating method offers many benefits, including increased hardness, improved thermal stability, and superior we...Read more -

Several Common Target Materials

1. Chromium target Chromium as a sputtering film material is not only easy to combine with the substrate with high adhesion, but also chromium and oxide to generate CrO3 film, its mechanical properties, acid resistance, thermal stability are better. In addition, chromium in the incomplete oxidati...Read more