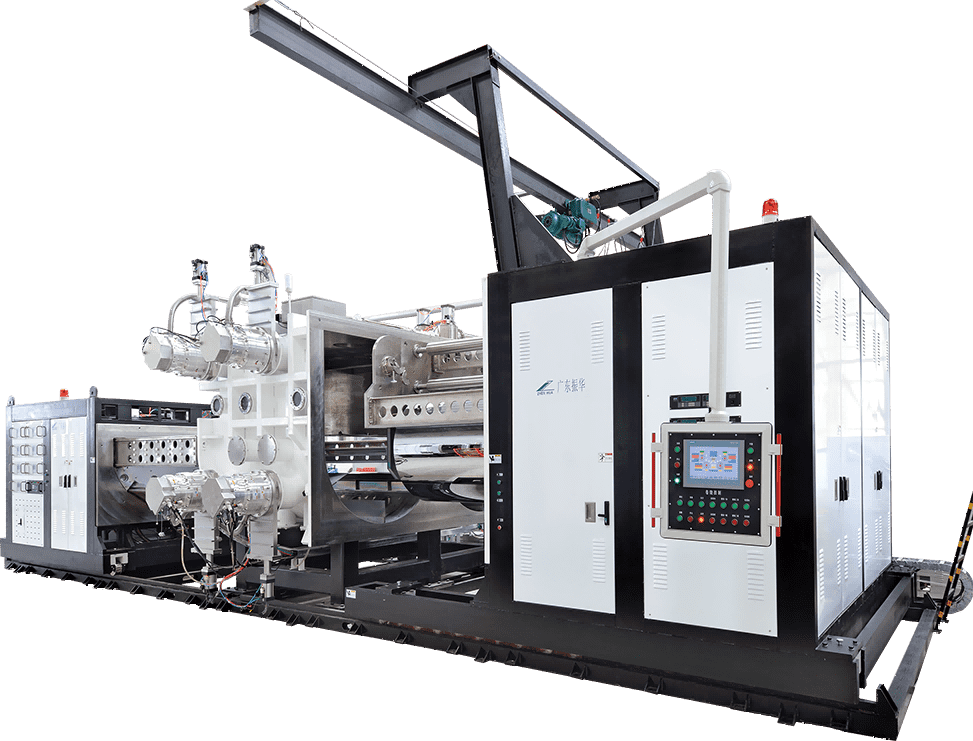

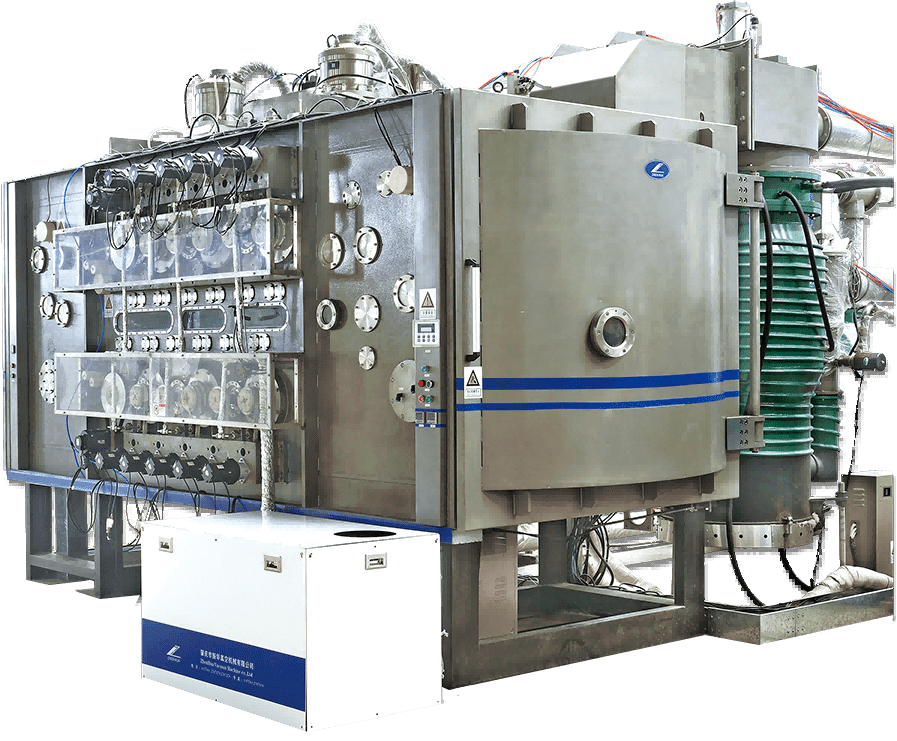

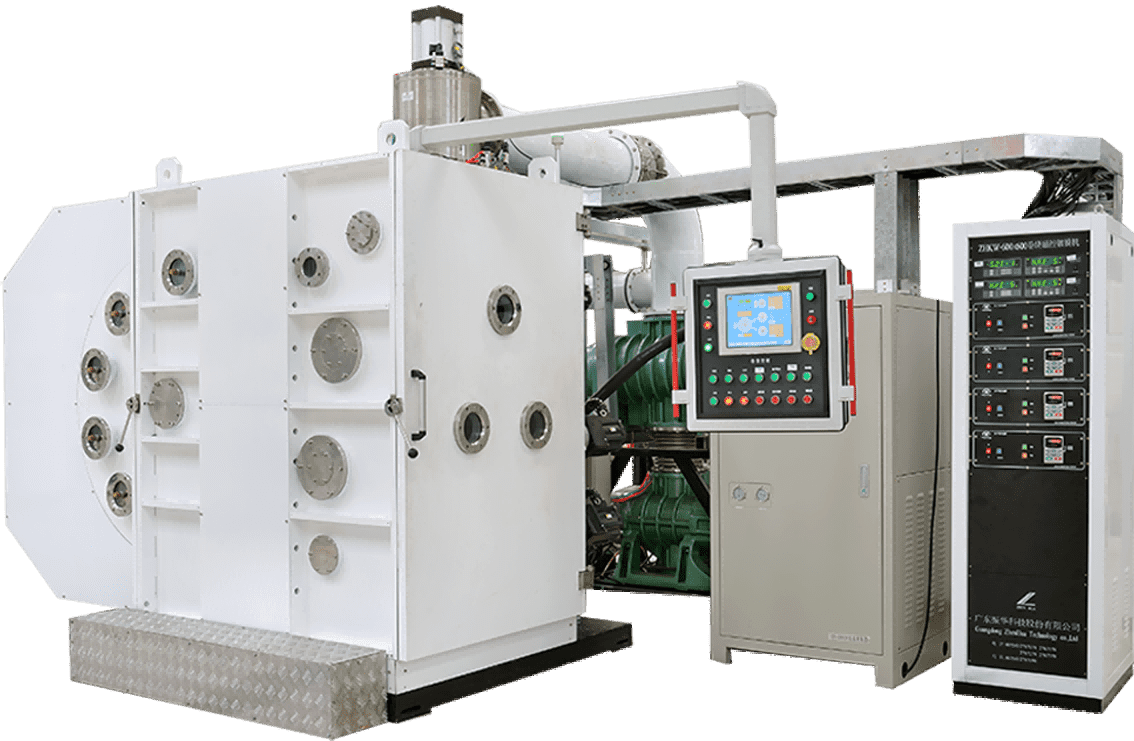

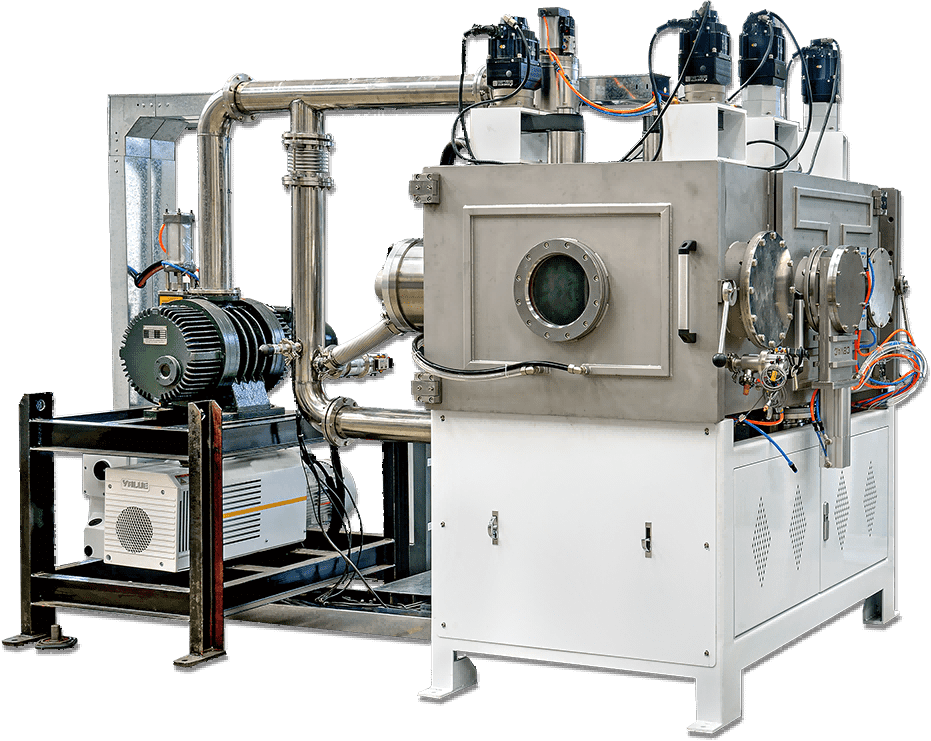

PRODUCT DESCRIPTION

This series of equipment converts the coating materials with low melting point and easy to evaporate into nano particles by heating in the medium frequency induction furnace or evaporation molybdenum boat, and deposits them on the surface of the workpiece to form a film. The rolled film is placed in the vacuum coating room, and the winding structure is driven by the motor. One end receives the film and the other puts the film. It continues to pass through the evaporation area to receive the coating particles and form a dense film layer.

Equipment features:

1. Low melting point coating material is thermally evaporated with high evaporation rate. The roll film clings to the cold drum to quickly take away the evaporation heat. The roll film has little effect on heating and will not deform. It is often used for coating on PET, CPP, OPP and other roll films.

2. Add different parts, which can be coated with films with separator strips and zinc aluminum alloy films, which are mainly used for coating capacitor films, electrical line films, etc.

3. Resistance evaporation molybdenum boat or medium frequency induction furnace can be configured as required, and the coating material has a wide range of applications. Commonly used evaporation materials include aluminum, zinc, copper, tin, silicon oxide and zinc sulfide.

The equipment is mainly used for coating capacitor film, electrical film, food and other articles packaging film, decorative color film, etc. The equipment adopts five motor drive technology and constant speed and constant tension control to prevent wrinkle. The vacuum pump group is fully automatic in the process of air extraction and film removal, and the process adjustment is easy. The equipment has large loading capacity and fast film moving speed, up to about 600m / min and above. It is a mass production equipment with large capacity.

| Optional models | Equipment size ( width ) |

| RZW1250 | 1250(mm) |