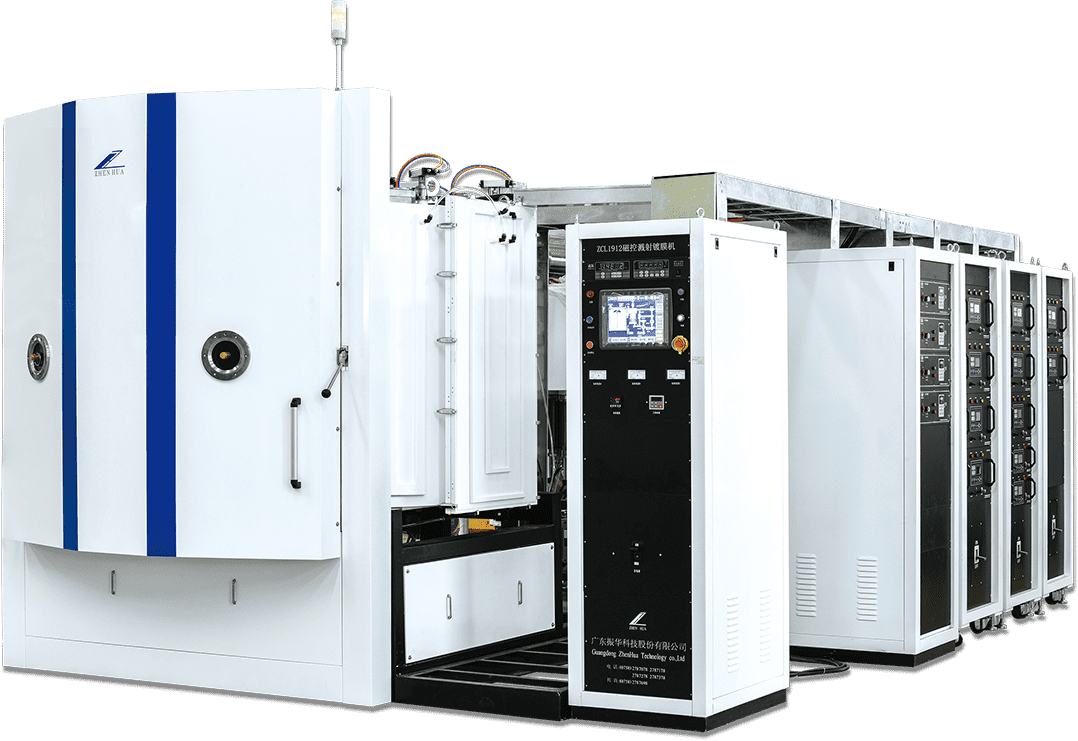

Vacuum Evaporation Coating Equipment - China Manufacturers, Suppliers, Factory

We can constantly satisfy our respected customers with our good high quality, good price tag and good support due to we have been additional specialist and extra hard-working and do it in cost-effective way for Vacuum Evaporation Coating Equipment, Continuous Coil Coating Line , Pvd Semiconductor Machine , Metal Pvd Vacuum Coating Equipment ,Drill Tools Pvd Coating Machine Manufacturer . We welcome new and previous clients from all walks of lifestyle to get in touch with us for long term business relationships and mutual accomplishment! The product will supply to all over the world, such as Europe, America, Australia,Cancun, Hanover,Lyon, Boston.Why we can do these? Because: A, We are honest and reliable. Our items have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It might be highly appreciated.

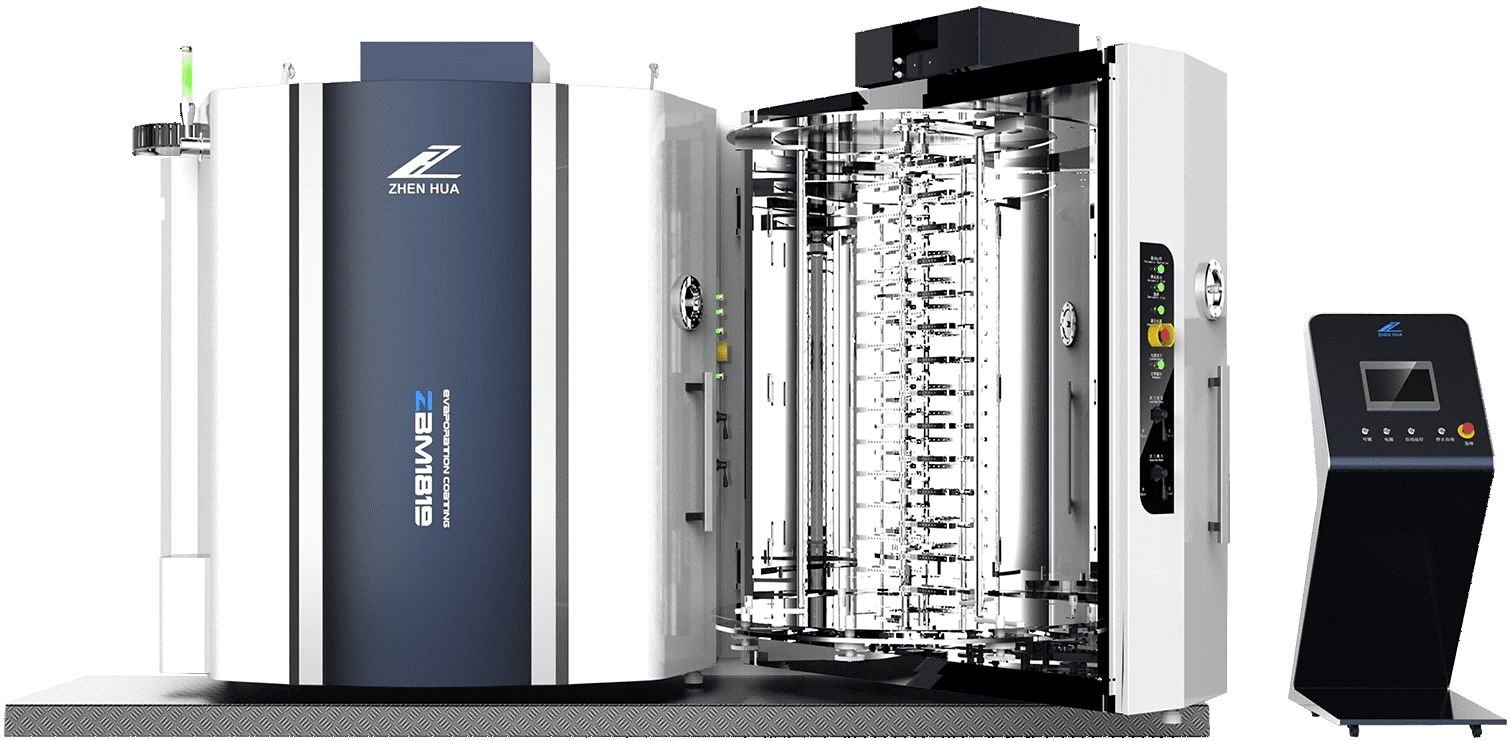

Related Products