PRODUCT DESCRIPTION

The equipment adopts cathode arc ion coating technology and is equipped with advanced IET etching system. After treatment, the product can directly deposit hard coating without transition layer. At the same time, the traditional arc technology is upgraded to the permanent magnet plus electromagnetic coil scanning technology. This technology can effectively enhance the ion energy, improve the ionization rate and target utilization rate, accelerate the arc spot movement speed, effectively inhibit the generation of droplets, reduce the roughness of the film, and lower the friction coefficient of the film. Especially for the aluminum target, it can significantly improve the service life of the workpiece. Equipped with the latest lightweight 3D fixture, the uniformity and stability are better.

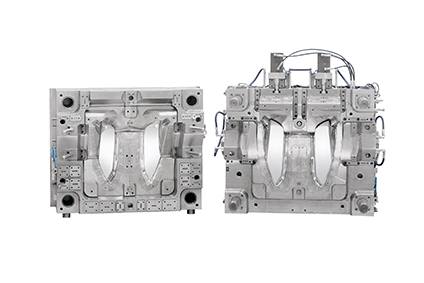

The equipment can be coated with AlTiN / AlCrN / TiCrAlN / TiAlSiN / CrN and other high-temperature super hard coatings, which have been widely used in mould, cutting tools, punches, auto parts, plunger and other products.

Technical features

1. Enhanced plasma, strong electromagnetic rotating scanning moving cold cathode, strong diffraction, dense film.

2. long sputtering distance, high energy and good adhesion.

3. The distance of arc striking anode can be adjusted without shutdown for maintenance.

4. The turnover track structure is convenient to replace and maintain the cold cathode.

5. the arc spot position is controllable, and different magnetic field modes can be adjusted according to different materials.

Examples of coating properties

| Coatings | Thickness (um) | Hardness (HV) | Max temp(℃) | Color | Application |

| Ta-C | 1-2.5 | 4000-6000 | 400 | Black | Graphite, carbon fiber, composites, aluminum and aluminum alloys |

| TiSiN | 1-3 | 3500 | 900 | Bronze | 55-60HRC stainless steel cutting, fine finishing |

| AlTiN-C | 1-3 | 2800-3300 | 1100 | Bluish grey | Low hardness stainless steel cutting, forming mould, stamping mould |

| CrAlN | 1-3 | 3050 | 1100 | Grey | Heavy cutting and stamping mould |

| CrAlSiN | 1-3 | 3520 | 1100 | Grey | 55-60HRC stainless steel cutting, fine finishing, dry cutting |

Optional models

| HDA0806 | HDA1112 |

| φ850*H600(mm) | φ1100*H1200(mm) |