1. Surface-Treatment Requirements Driven by New Energy Vehicles and Intelligent Cockpits

In recent years, the rapid development of new energy vehicles (NEVs) and intelligent cockpits has accelerated the adoption of large-format center displays, smart rear-view mirrors, in-vehicle touch panels, ambient-lighting components, and various interior and exterior parts. OEMs are raising the bar for the size specifications, appearance uniformity, and long-term reliability of automotive optical glass—requirements that are now being transmitted upstream to raw-material suppliers and surface-treatment processes.

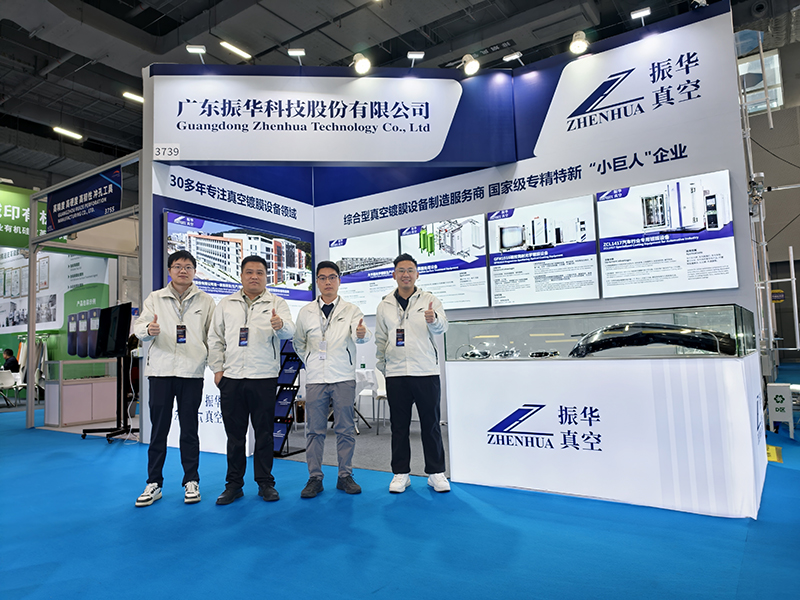

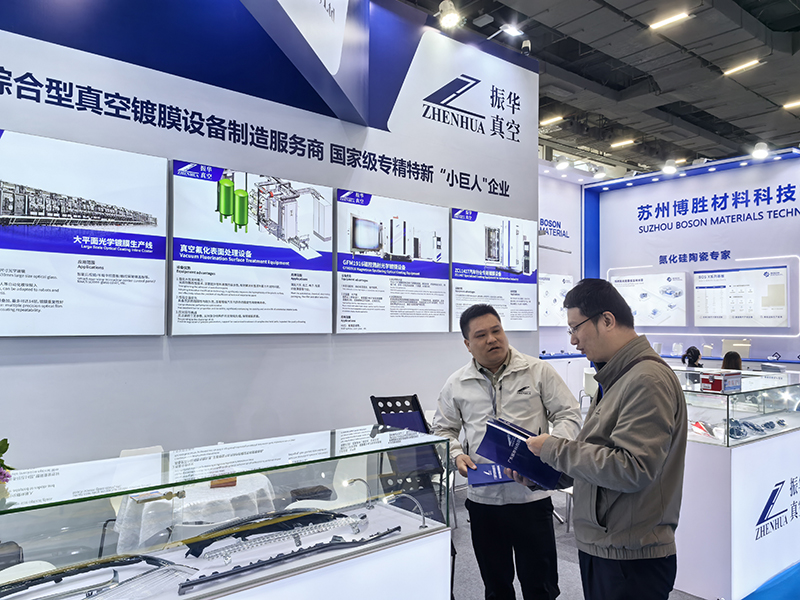

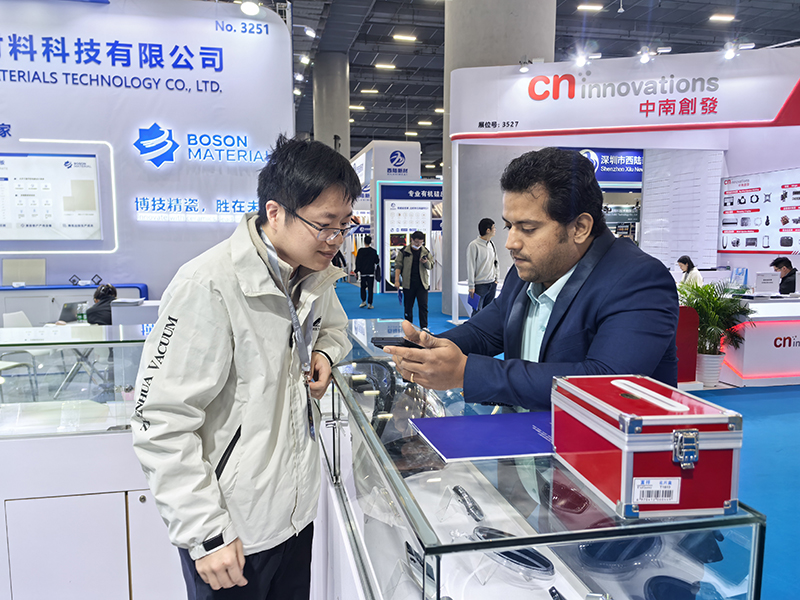

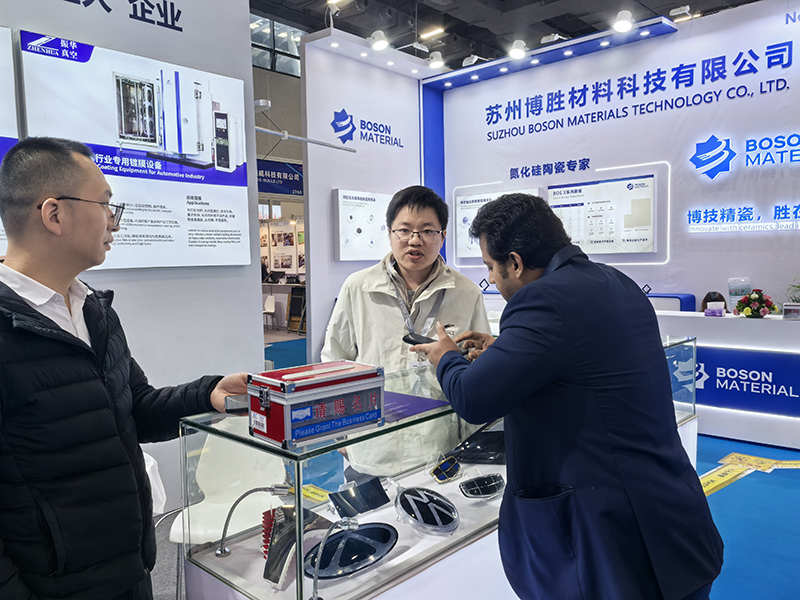

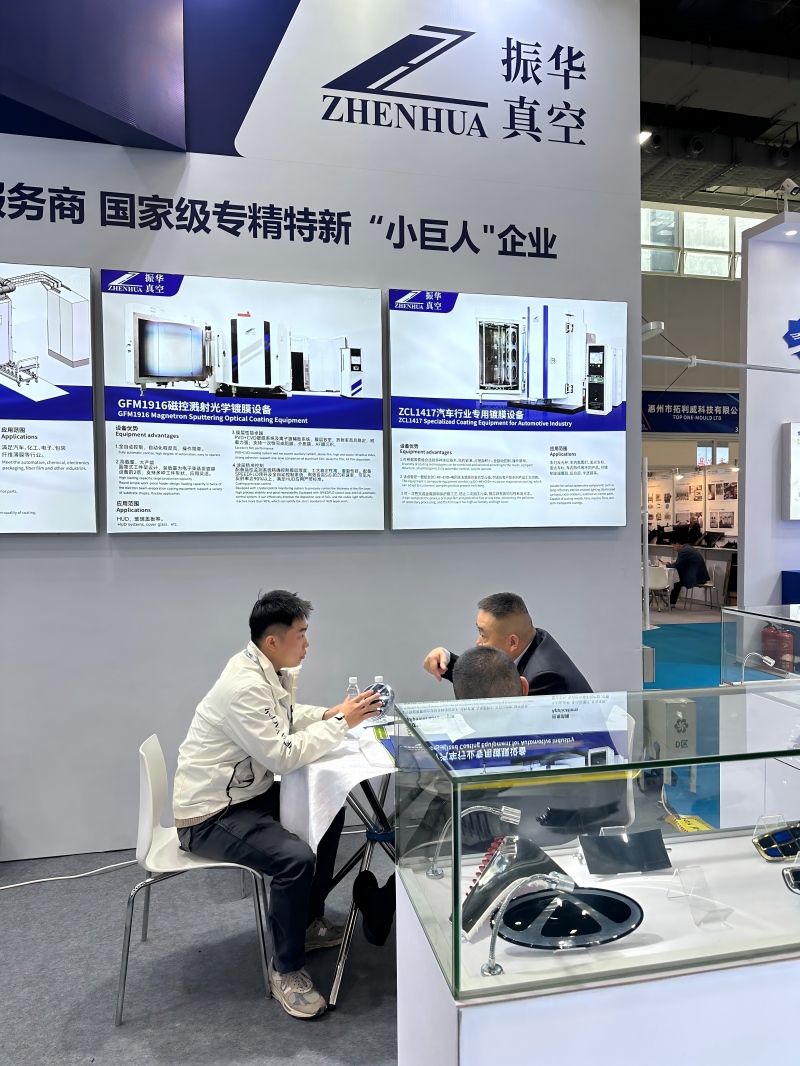

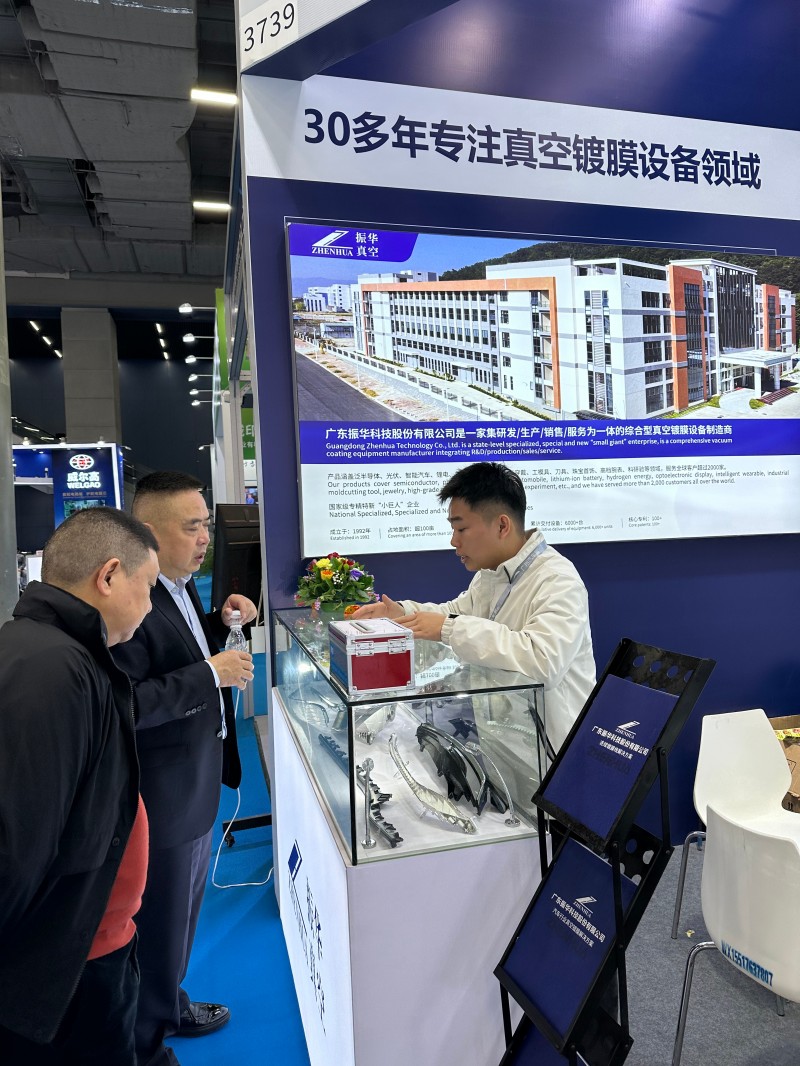

Against this backdrop, Zhenhua Vacuum participated in the 2025 Guangzhou International Automotive Technology Expo from November 21 to 24 (Booth 3739), presenting complete vacuum-coating and surface-treatment solutions for large automotive displays, interior trim components, and automotive lighting. During the exhibition, Zhenhua held in-depth discussions with industry partners on topics such as mass production scalability, process stability, and environmental compliance.

2. Exhibition Highlights: Zhenhua’s Automotive Surface-Treatment Solutions Draw Strong Interest

1) Large-Format Optical Coating Solutions for Scalable, Stable Mass Production

During the show, Zhenhua focused on two major application domains—automotive optical glass and decorative components—and showcased a comprehensive portfolio of surface-treatment technologies that attracted significant attention from automotive manufacturers and Tier-1 suppliers.

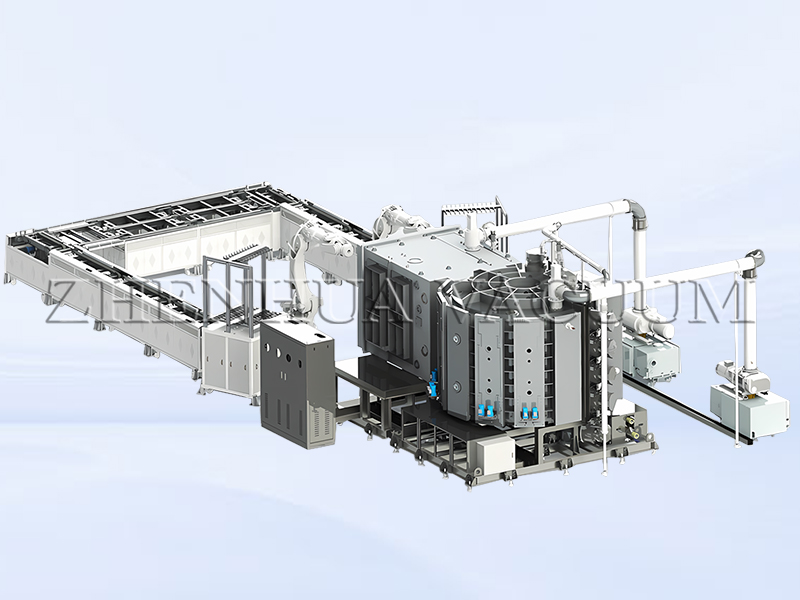

In the large-format automotive glass segment, Zhenhua presented its Large-Panel Optical Coating Production Line and the SOM-2550 Multi-Chamber Magnetron Sputtering Optical Coater, designed for oversized center displays, smart mirrors, and in-vehicle touch panels.

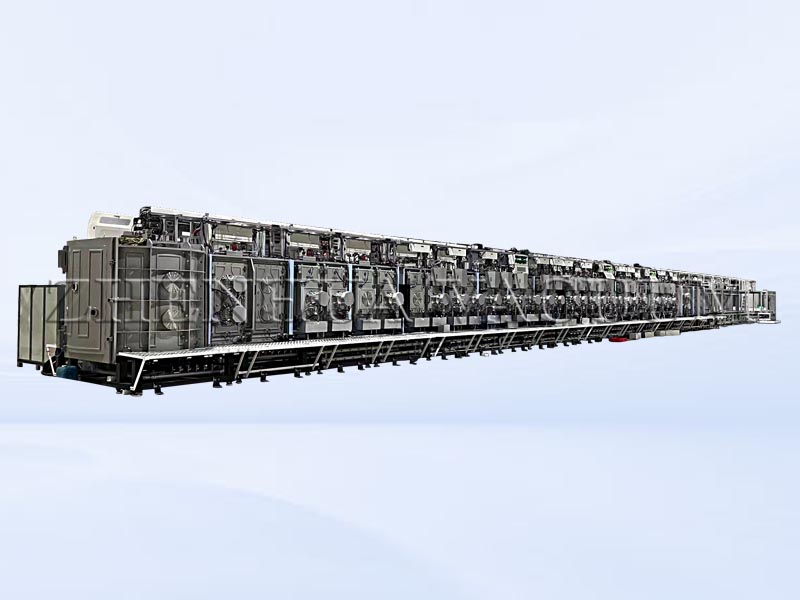

Large-Panel Optical Coating Production Line: Continuous, Uniform Coating for Oversized Glass

This production line became one of the most notable attractions due to its ability to deliver continuous and highly uniform mass production of large glass substrates.

Maximum substrate size: 1600 mm × 630 mm

Throughput: ~50 seconds per cycle

Compatible with robotic handling and automated loading/unloading

Supports up to 14 layers of precision optical coating, enabling flexible process integration for multiple optical stacks

SOM-2550 Multi-Chamber Magnetron Sputtering Coater: High Throughput + Multi-Process Integration

The system also drew strong interest from visiting customers due to its multi-chamber architecture and significantly enhanced productivity.

Single-run coating area: ~8 m²

Overall throughput: ~3.2× higher than traditional e-beam evaporation coaters

Supports AR / NCVM, DLC, AF and other process combinations

Capable of producing 9H ultra-hard AR+AF coatings, improving scratch resistance and wear performance while maintaining production efficiency and coating reliability

2) Automotive Interior Trim & Lighting Coating Solutions: Process Integration and Environmental Compliance

For automotive interior components and lighting applications, the ZCL1417 Automotive Coating System and the ZBM1819 Headlamp Protective-Film Coater gained strong interest from trim and lighting manufacturers due to their emphasis on process integration and environmentally friendly operation.

ZCL1417 Automotive Coater: Metal + Protective Films in One Integrated System

Integrates both metal-film and protective-film deposition within a single system

Eliminates inter-process transfers and reduces work-in-process (WIP)

Minimizes contamination risks and improves appearance uniformity

Tailored for complex decorative parts and automotive ambient-lighting components

During the show, multiple trim and ambient-lighting suppliers visited the booth to learn more about system configurations and real-world production results.

ZBM1819 Headlamp Protective-Film Coater: Vacuum-Deposited Functional Coatings, No Paint Required

Forms headlamp functional coatings fully via vacuum deposition

No primer or top-coat spraying, significantly reducing VOC emissions

Meets long-term performance requirements for transmittance, weather resistance, and abrasion resistance

Headlamp manufacturers expressed strong interest in its applicability for new vehicle programs and in assessing its feasibility as an alternative to traditional wet-coating processes—seeking improved environmental compliance while optimizing production lines and overall cost structures.

3. Deepening Focus on Automotive Applications to Support High-Quality Industry Development

Throughout the Guangzhou International Automotive Technology Expo, Zhenhua Vacuum exchanged insights with customers from the automotive display, intelligent cockpit, interior trim, and lighting sectors. Discussions covered equipment selection, process development, production-line planning, and cost management.

Looking ahead, Zhenhua Vacuum will continue strengthening its technology leadership in automotive applications, advancing innovations in vacuum coating and surface-treatment processes. With continuous investment in high reliability, high throughput, and green manufacturing, Zhenhua aims to deliver more advanced equipment and coating solutions to the NEV and intelligent-vehicle supply chain—supporting the industry’s pursuit of high-quality and sustainable development.

—This article was published by vacuum coating equipment manufacturer Zhenhua Vacuum

Post time: Nov-25-2025