In recent years, with the accelerated mass production of smart vehicles, demand for optical structural components such as in-vehicle displays, smart rearview mirrors, and large-size center console glass has surged rapidly. The market has imposed increasingly stringent technical requirements on optical coating equipment capable of large-area, high-uniformity, and stable mass production. Simultaneously, the semiconductor advanced packaging sector continues to evolve driven by TGV 3D structure technology, creating an urgent need for coating capabilities targeting complex through-holes with high aspect ratios. Equipment faces sustained pressure to upgrade in process precision, window width, and material compatibility.

Driven by these dual industry forces, high-performance vacuum coating equipment has become a critical enabler of industrial upgrading. To showcase its latest engineering achievements, Zhenhua Vacuum presented a comprehensive lineup of core products at the 2025 Guangdong Vacuum & Semiconductor Exhibition from November 13–15. The company demonstrated its coating solutions across optical components, advanced packaging, and electronic component manufacturing. The booth attracted significant attention from professionals in optoelectronics, packaging, and automotive manufacturing, generating strong technical exchanges and clear cooperation intent.

Precise Response to Industry Needs, Widely Recognized by Customers

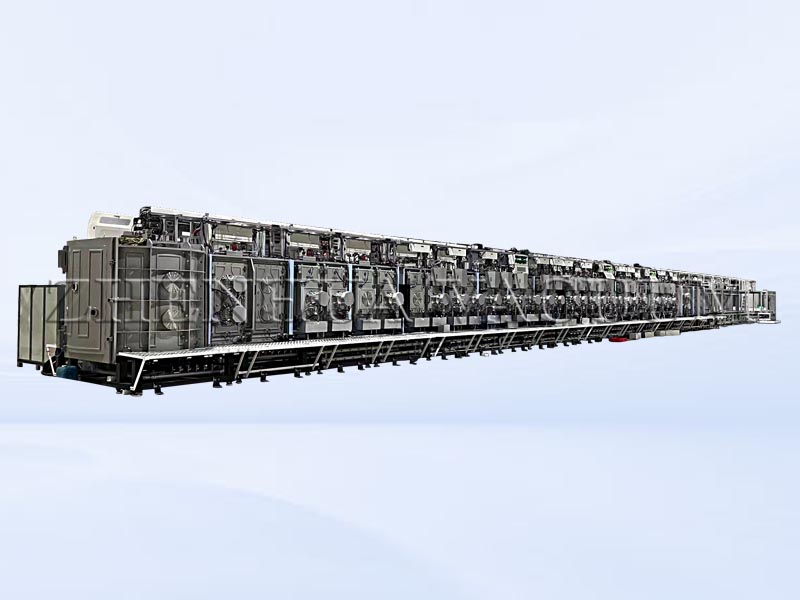

Automotive Optical Glass Coating Solutions: Large Format, High Efficiency, Mass Production Ready

Zhenhua Vacuum’s large-area optical coating inline coater delivers core advantages in “large-area processing, high-cycle efficiency, and exceptional coating uniformity,” providing critical equipment support for the mass production of smart automotive optical components. This line stably processes ultra-large glass substrates up to 1600mm × 630mm, achieves continuous production cycles as low as 50 seconds, and successfully stacks 14-layer precision optical coatings. Its outstanding performance precisely meets the urgent demand for large-format, high-consistency coating in automotive displays, optical enhancement, and anti-glare applications, sparking in-depth technical discussions with multiple leading automotive electronics manufacturers on-site.

2.Advanced Packaging Coating Solutions: Breakthrough in High Aspect Ratio Processes

In the advanced packaging sector, Zhenhua Vacuum’s through-hole coating equipment garnered significant attention for its exceptional process capability on high aspect ratio structures. Capable of handling ultra-fine through-holes as small as 30 microns, the equipment achieves uniform coating on structures exceeding 10:1 aspect ratio. This effectively overcomes the technical bottleneck of deep hole metallization in 3D integration, providing reliable equipment support for advanced packaging processes like TGV/TSV.

In electronic component manufacturing, the company’s continuous coating production line for ceramic capacitors and resistors employs an innovative copper electrode sputtering process. This approach delivers significant advantages in conductivity, sulfidation resistance, and overall cost control, making it a focal point of attention and discussion among on-site electronic component manufacturers.

No.2 Looking Ahead: Driving Industry Advancement Through Technology

Looking forward, the pace of technological iteration in automotive electronics and semiconductor packaging will continue to accelerate. Zhenhua Vacuum will persist in innovation-driven development, continuously advancing high-performance coating equipment to deliver more efficient, stable, and forward-looking vacuum coating solutions for global customers.

—This article was published by vacuum coating equipment manufacturer Zhenhua Vacuum

Post time: Nov-26-2025