As vehicle intelligence advances, the smart cockpit has become a key driver of value in modern automotive design. Core components such as in-vehicle displays, camera monitor systems (CMS), head-up displays (HUDs), illuminated emblems, and ambient lighting modules now require enhanced visual appearance, integrated functionality, and environmental reliability—driving demand for high-performance optical thin film coatings.

Focusing on key smart cockpit application scenarios, Zhenhua Vacuum provides comprehensive vacuum coating solutions covering automotive displays, glass cover panels, smart mirrors, HUDs, and illuminated interior components, helping component manufacturers increase product value and achieve stable mass production.

No.1 Large-Area Optical Coating Line: Solving Coating Challenges for CMS Smart Mirror Glass

As CMS smart mirrors replace traditional exterior mirrors, their glass components have evolved toward larger formats, slimmer profiles, and multifunctional integration. However, large-format optical glass poses significant coating challenges—especially membrane thickness non-uniformity and process instability—due to its deformation and edge coating control difficulties during deposition.

Zhenhua Vacuum’s Large-Area Optical Coating Line is engineered specifically for such applications, offering:

Ultra-large substrate compatibility: Vacuum chamber supports glass substrates up to 1600mm × 630mm, ideal for elongated or non-standard CMS mirror structures.

Continuous coating architecture: Achieves a fast cycle time of 50 seconds, enabling seamless integration with upstream and downstream automation systems.

Multilayer thin-film support: Capable of depositing up to 14 precision optical layers with high repeatability, ensuring excellent performance in reflectance, color tuning, and durability.

Application examples: CMS mirrors, automotive-grade reflective glass, functional conductive glass.

No.2 SOM-2550 Inline Magnetron Sputtering System: Advancing Automotive Displays Toward High Clarity and Durability

Central control displays, instrument panels, and rear entertainment screens are evolving toward higher resolution, brightness, and low reflectance. Simultaneously, glass cover panels must meet requirements for 9H surface hardness and anti-smudge properties, demanding high film uniformity and dense, multi-functional coatings—areas where traditional electron-beam evaporation often falls short.

The SOM-2550 Inline Magnetron Sputtering Coater addresses these challenges by offering:

High throughput production: Coating width up to 1100mm, effective area up to 8m², delivering 3.2× the capacity of conventional systems.

Superior uniformity control: Thickness uniformity better than ±1%, ideal for automotive-grade displays requiring consistent brightness and color.

Multi-functional optical film stack: Supports integration of AR (Anti-Reflection), NCVM (Non-Conductive Vacuum Metallization), and AF (Anti-Fingerprint) layers. Transmission reaches 95%, reflectance below 1%, and surface hardness up to 9H.

Application examples: Center display cover glass, touch-sensitive panels.

No.3 GFM1916 Optical Sputtering Coater: High-Precision Coating System for HUD Applications

The projection glass used in Head-Up Displays (HUDs) demands ultra-uniform optical coatings with stable refractive index, strong adhesion, and excellent environmental resistance. In traditional processes, insufficient film density can lead to fogging, delamination, and optical drift under thermal cycling or humidity stress—compromising the display quality.

Zhenhua’s GFM1916 Magnetron Sputtering Coater was developed to overcome three major pain points in HUD applications: high performance, high stability, and high complexity, offering:

Multi-shape substrate compatibility: Rotary drum holder with planetary motion supports simultaneous coating of various shapes, doubling the loading capacity versus conventional equipment.

Advanced multilayer stack integration: Combines PVD, CVD, and high-energy ion sources in one platform, enhancing film density, adhesion, and optical performance.

Precision monitoring system: Features crystal sensor feedback and SPEEDELO closed-loop control, enabling dynamic thickness regulation with reflectance exceeding 90%, meeting high-end HUD optical standards.

Environmental durability: Deposited films resist moisture adsorption, maintaining optical integrity under humid or thermal shock conditions.

Application examples: HUD projection glass, automotive glass covers.

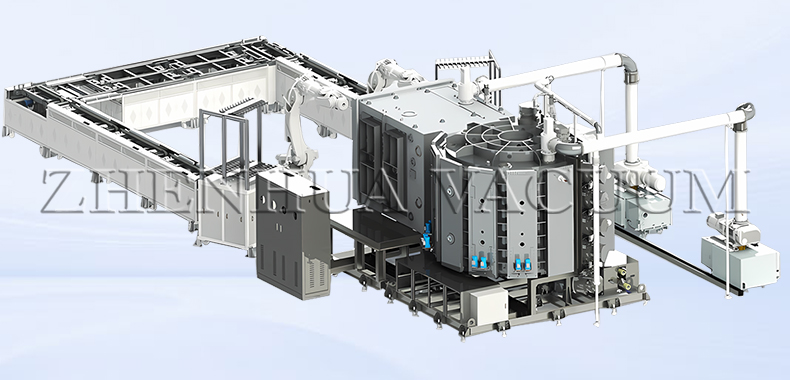

No.4 ZCL1417 Multi-Process Coating System: Supporting Flexible Coating for Automotive Interior Components

As ambient lighting design becomes increasingly refined, illuminated logos, light guides, and other decorative functional parts demand coatings that are high-gloss, low-contamination, scalable, and flexible. Traditional multi-step processes—separately applying metallic and protective layers—often result in scratches, contamination, and yield loss due to excessive handling.

Zhenhua’s ZCL1417 Multi-Process Coating System is tailored for scenarios requiring frequent product changes and complex layer stacks, enabling flexible, high-yield manufacturing:

Integrated multi-process platform: Combines magnetron sputtering, resistance evaporation, CVD, and mid-frequency ion cleaning. Coating schemes can be flexibly configured based on product requirements.

One-pass multilayer deposition: Enables simultaneous deposition of metallic and protective layers, reducing handling and contamination risk.

Compact vertical dual-door design: Space-efficient layout fits into existing production lines, allowing rapid model switching and supporting modular project deliveries.

High automation: Full-process automation minimizes reliance on operator experience, enhancing consistency and reducing labor intensity.

—This article was published by vacuum coating equipment manufacturer Zhenhua Vacuum

Post time: Jul-23-2025