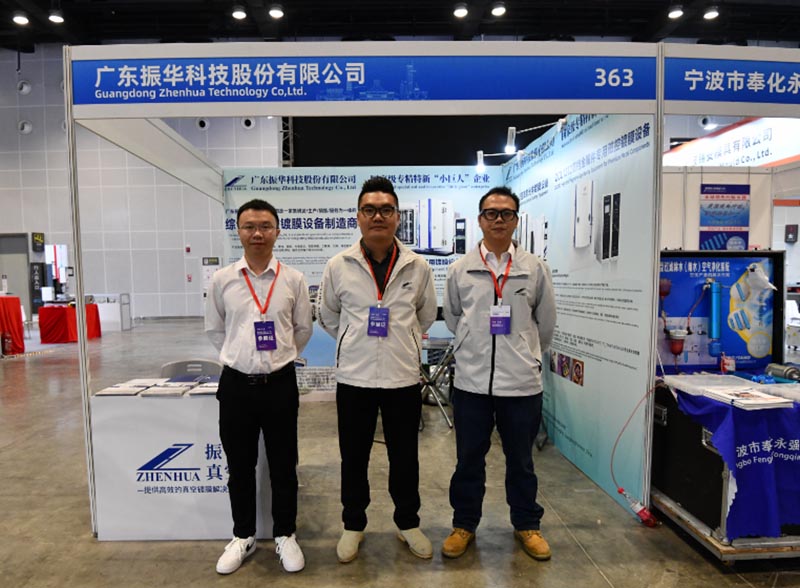

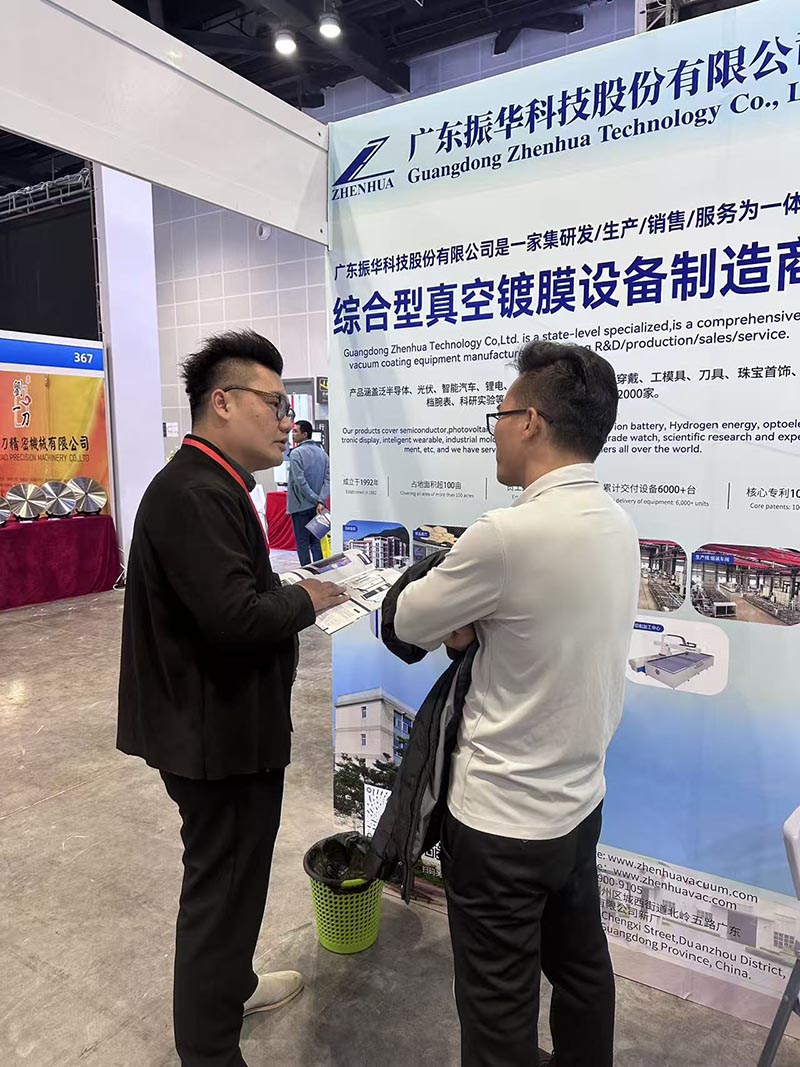

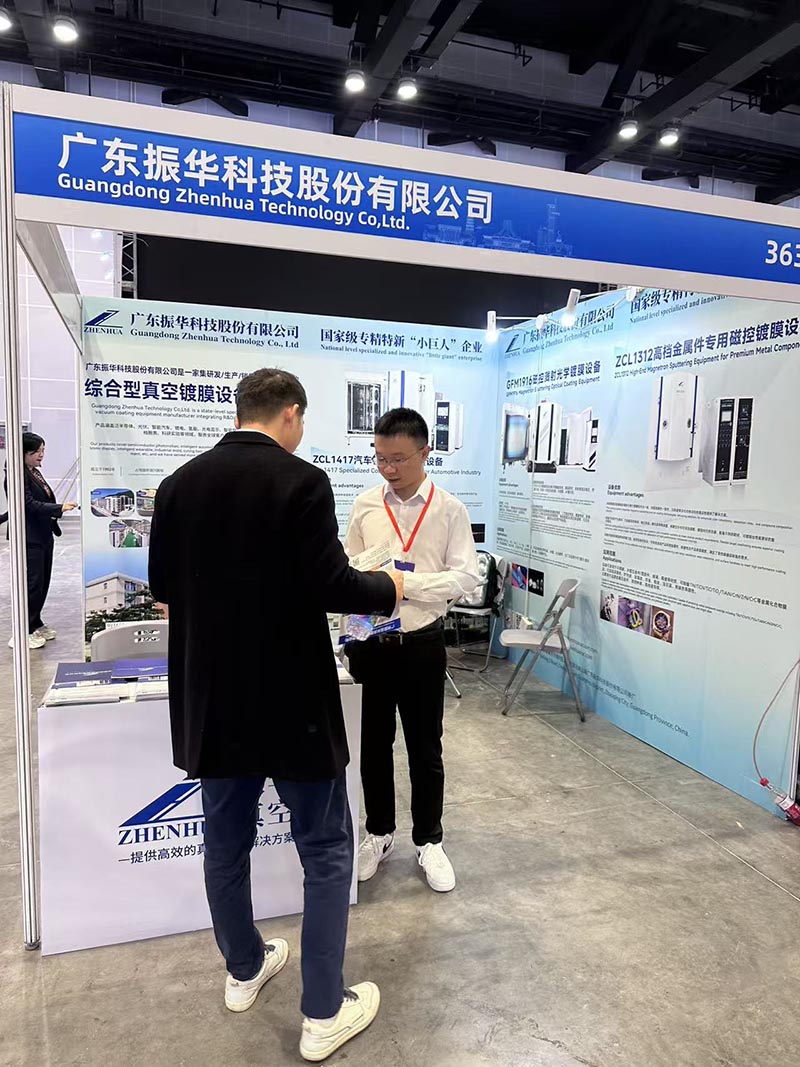

Against the backdrop of accelerated global manufacturing upgrades, demands for high-end decorative parts and automotive trims continue to rise in terms of aesthetic texture, durability, and batch consistency. More efficient and stable coating processes are becoming crucial for enterprises to capture market share and enhance brand value. In response to this trend, Zhenhua Vacuum participated in the China-ASEAN International Industrial Expo (Guangxi) held from November 22 to 24 in Guangxi. At Booth 363, the company showcased its advanced coating solutions for high-end decorative components and automotive trim, leveraging vacuum coating technology to serve domestic and international clients while driving quality and efficiency improvements in manufacturing.

I. Zhenhua Vacuum’s High-End Decorative and Automotive Automotive Interior/Exterior Coating Solutions

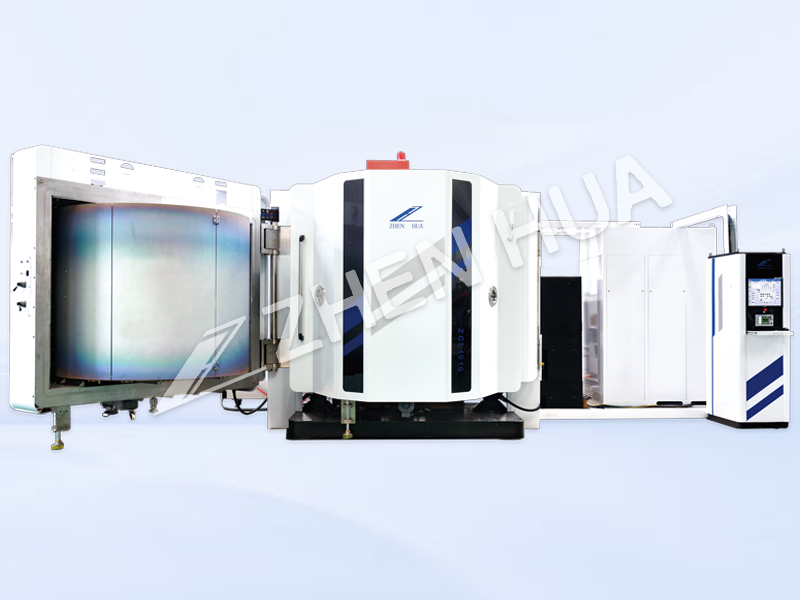

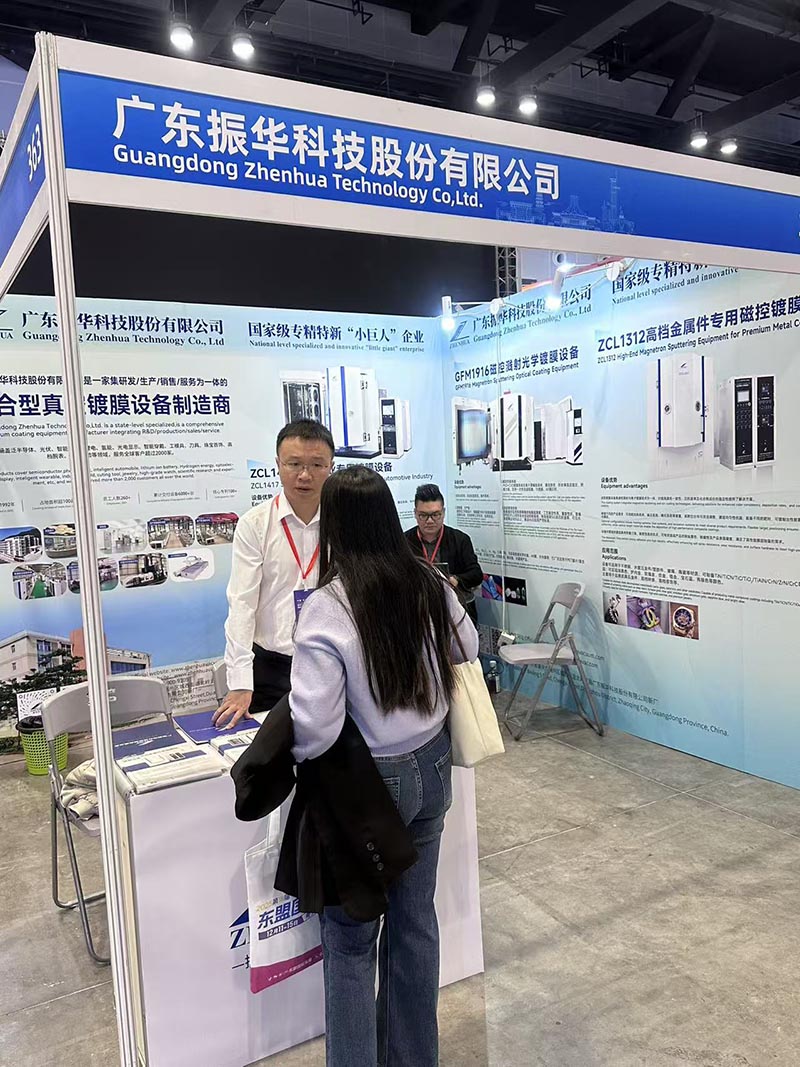

During the exhibition, Zhenhua Vacuum highlighted multiple equipment models tailored for high-end decorative and automotive trim applications. Among them, the GFM1916 Magnetron Sputtering Optical Coating Equipment garnered significant interest from on-site clients. This equipment boasts approximately double the production capacity of traditional electron beam evaporation systems and features a crystal control monitoring system for precise film thickness control. It has established mature applications in PET films/composite panels, smartphone cover glass, 3C electronics, sunglasses, perfume bottles, crystal products, and more, making it one of the most inquired-about and discussed models at the booth.

For high-end decorative applications such as branded leather goods hardware, luxury watches, and jewelry, Zhenhua Vacuum simultaneously showcased the ZCL1312 magnetron coating equipment specialized for premium metal components. Through optimized target positioning and process design, this equipment ensures both color consistency and coating uniformity. It delivers strong adhesion and high density, significantly enhancing products’ salt spray resistance, wear resistance, and surface hardness. This makes it ideal for meeting the long-term, stable supply demands of high-end metal decorative components.

For automotive trim applications, Zhenhua Vacuum highlighted the ZCL1417 coating equipment tailored for the automotive industry. This system serves diverse product applications including headlight reflectors, interior ambient lighting, illuminated logos, radar-integrated emblems, and interior trim components. This equipment completes both metal coating and protective film processes within a single chamber, reducing secondary contamination risks from multiple steps and handling. It delivers uniform, high-gloss coatings and supports various process combinations—including metal films, reactive films, and semi-transparent films—meeting OEMs’ aesthetic requirements while ensuring long-term reliability.

II. Conclusion

Through this China-ASEAN International Industry Expo (Guangxi), Zhenhua Vacuum showcased its coating equipment and process capabilities in high-end decorative components and automotive trim, further strengthening connections with domestic and international clients. Moving forward, Zhenhua Vacuum will continue to deepen its expertise in specialized application scenarios, continuously optimize equipment performance and process services, and transform the attention and trust gained during the exhibition into more tangible projects and long-term collaborations, empowering the high-quality development of global manufacturing.

—This article was published by vacuum coating equipment manufacturer Zhenhua Vacuum

Post time: Nov-27-2025