Addressing Adhesion and Durability Challenges of Waterborne Coatings on Automotive Plastic Components

Application

Driven by automotive lightweighting trends and increasingly stringent environmental regulations, waterborne coating systems are rapidly replacing conventional solvent-based painting processes and are now widely applied to automotive interior plastic components.

However, plastic substrates typically exhibit low surface energy and complex geometries, which pose significant challenges to coating adhesion and long-term durability. Vacuum fluorination surface treatment technology has therefore emerged as a critical pretreatment process for waterborne coating applications on automotive plastic parts.

Customer Pain Points

Insufficient adhesion of waterborne coatings

Conventional surface treatments often fail to sufficiently increase surface wettability, leading to issues such as coating delamination and peeling.

Limited durability and consistency

Under long-term use and varying temperature and humidity conditions, coating stability on interior plastic components is difficult to maintain.

Non-uniform treatment of complex geometries

Components with complex contours, deep cavities, and intricate structures are prone to uneven surface modification, negatively affecting coating quality and production yield.

Zhenhua Vacuum Solution

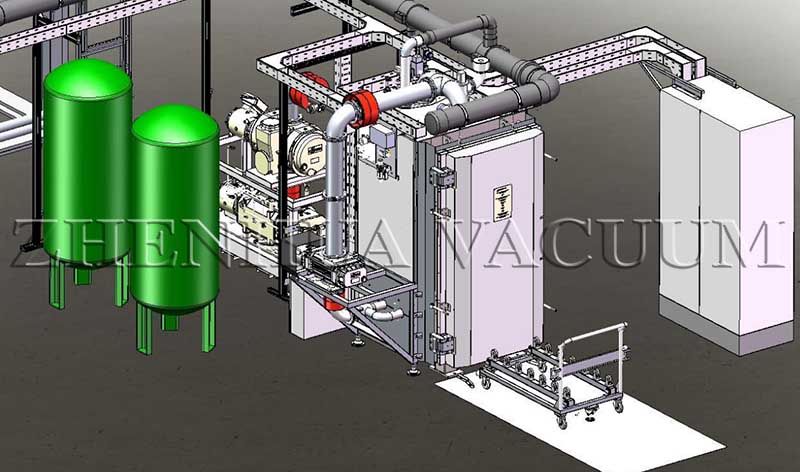

Zhenhua Vacuum has developed a vacuum fluorination surface treatment system that modifies plastic surfaces through a controlled fluorination reaction.

Without compromising the intrinsic properties of the substrate, the process significantly enhances surface energy and chemical activity, providing a stable and reliable interface for subsequent waterborne coating processes. The solution is designed to meet the requirements of high-volume production with high consistency for automotive plastic components.

Plastic Surface Fluorination Equipment

Equipment Advantages:

Enhanced Adhesion for Waterborne Coatings

Utilizing an advanced surface modification mechanism, the system markedly improves surface wettability, effectively resolving adhesion issues associated with waterborne paints.

Comprehensive Performance Improvement

Delivers excellent barrier properties and long-term durability, significantly improving the stability and service life of automotive interior components.

Capability for Complex Geometries

Flexible process parameter control enables customized treatment of complex-shaped parts, ensuring uniform surface modification and consistent coating quality.

Application Scope: Applicable to a wide range of industries, including automotive, chemical processing, electronics, packaging, and fiber film materials.

–This article was published by vacuum coating equipment manufacturer Zhenhua Vacuum

Post time: Dec-25-2025