In the wave of automotive intelligence, the smart cockpit has become a core symbol of high-end vehicles. As the central hub of interaction, the display has evolved far beyond a “visual window” into a sophisticated system integrating touch control, dimming, and anti-glare functionalities.

Almost all of these functions rely on advanced thin-film coating technologies applied to glass surfaces—from anti-reflective (AR) films to conductive layers. Each thin film, like a “nerve ending,” directly influences the user experience.

However, as displays advance toward larger sizes, more diverse form factors, and higher functional integration, coating technology is no longer a simple scaling-up process. It has become a system-level challenge that spans across equipment design and process control.

1. Functional Integration: From Single-Layer to Complex Stacks

In traditional small-sized automotive displays, a single AR film was sufficient. In smart cockpits, however, displays must simultaneously achieve high transmittance, low reflectance, precise touch sensitivity, abrasion resistance, and even privacy protection. As a result, the thin-film system has evolved into multi-layer composite architectures, dramatically increasing complexity.

Take “touch + display” integration as an example. The key material is indium tin oxide (ITO) conductive film. Ensuring responsive touch requires good conductivity, but conductivity and optical transmittance are inherently contradictory. A thicker ITO film improves conductivity but reduces transmittance, making the display look dim. A thinner film improves optical clarity but weakens conductivity, causing touch latency.

The number of coating steps has expanded from 2–3 layers to 6–8 layers. Any nanometer-scale defects—such as pinholes or contamination—in early layers will cascade like a “domino effect,” compromising subsequent layers and rendering the entire panel defective. This demands not only precise layer-by-layer control, but also full-process cleanliness and parameter synergy.

2. Scaling Up: Three Physical Challenges of Large-Area Glass

To create an immersive cockpit experience, display sizes have expanded from 10-inch to 27-inch ultra-wide panels, and even to curved dome-shaped glass. Large-area substrates, however, introduce unique physical bottlenecks:

1. Thermal Stress Non-Uniformity

During magnetron sputtering, energetic particle bombardment locally heats the glass to 80–150 °C. Small substrates dissipate heat uniformly, but glass larger than 1.5 m experiences center-to-edge temperature gradients. The center heats quickly and cools slowly, while edges behave oppositely. This differential induces 0.1–0.3 mm warpage, degrading film uniformity, and in severe cases causes substrate cracking.

2. Edge Effect in Film Deposition

Sputtered particle flux is directional, and deposition rates at the edges are typically 10–15% lower than at the center. For an 18-inch panel, this results in thinner edge films, reducing brightness and causing color distortion. Although mitigations like multi-cathode coordination and magnetic field optimization exist, they significantly raise equipment complexity and process difficulty.

3. Substrate Support and Transfer Precision

Large glass substrates must be stably transferred inside vacuum chambers without deformation or scratches. For curved glass, support point distribution must be precisely calculated—too few points cause sagging; too many create “shadow zones.” Meanwhile, substrate transfer accuracy must be controlled within ±0.05 mm. Even minor deviations can damage the glass or compromise the vacuum environment, leading to full-batch rejection.

3. Quality Demands: The Nanometer-Level Consistency Threshold

As highly visible components, smart cockpit displays impose unprecedented uniformity requirements on coating thickness.

In conventional automotive displays, thickness uniformity within ±5% was acceptable. In premium cockpits, this tolerance has tightened to ±1.5%. Any deviation results in luminance non-uniformity or color shift, directly degrading user experience.

4. Zhenhua Vacuum’s Large-Area Optical Coating Solution

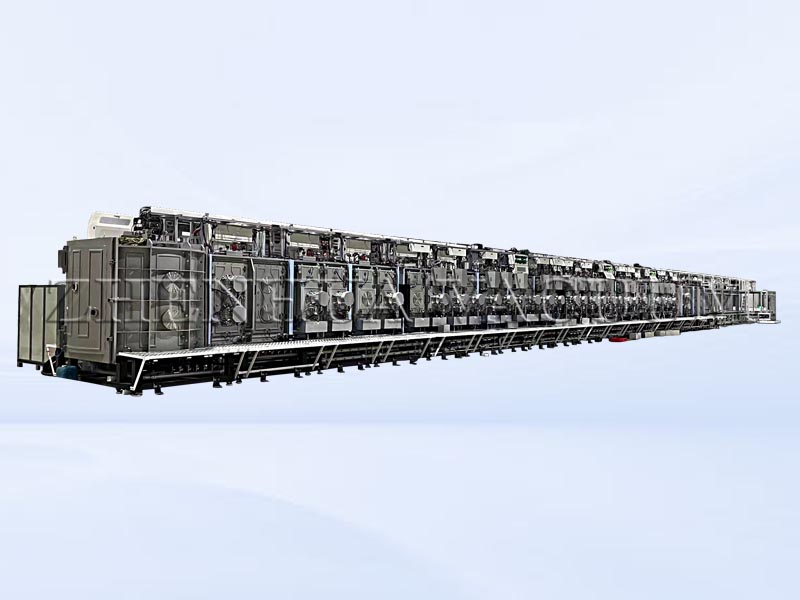

To address these coating challenges, Zhenhua Vacuum’s large-area optical coating production line provides an integrated solution:

Large-Format Stability

Capable of mass production of 1600 mm × 630 mm glass panels, equipped with zoned temperature control and high-precision transfer platforms. This prevents warpage and cracking, overcoming large-area physical bottlenecks.

High Throughput

Achieves continuous coating cycles of 50 s per substrate, supported by automated loading/unloading systems. It ensures both stability and efficiency, enabling automotive OEMs to scale multi-display cockpit production.

Multi-Layer Capability

Supports up to 14 optical layers with high deposition repeatability. Complex thin-film stacks can be completed within a single process cycle, ensuring structural consistency across the entire panel.

Application Scope: Smart rearview mirrors, automotive central control panels, and touch screen cover glass.

5. Conclusion

The rising complexity of smart cockpit coatings reflects the tension between functional requirements and process limitations. From multi-layer integration, to large-area physical constraints, to nanometer-scale uniformity control, every step pushes the boundaries of thin-film technology.

Ultimately, breakthroughs require deep synergy across materials, process engineering, and equipment design. Zhenhua Vacuum’s large-area optical coating production line embodies this integration—addressing mass-production bottlenecks while shifting coating from an experience-driven process to a science-driven discipline.

As applications like multi-screen integration and transparent displays become mainstream, demands on coating will only intensify. In this race, the ability to deliver stable, consistent large-area coatings will define who gains the upper hand in next-generation automotive competition.

—This article was published by vacuum coating equipment manufacturer Zhenhua Vacuum

Post time: Sep-18-2025