1. The “Pain Points” Emerging in the Era of Large-Format Displays

With the rapid growth of the new energy vehicle (NEV) sector entering its “golden era,” the smart cockpit has become the core interaction hub, accelerating toward larger, multi-screen, and integrated designs. From early small-sized infotainment panels to today’s cross-car triple displays and even full-width panoramic screens, the automotive display has evolved beyond a simple information carrier—it now defines both technological sophistication and user experience.

However, behind this wave of large-format adoption, display quality challenges have become increasingly prominent. Many drivers report that under strong ambient light, in-vehicle displays suffer from severe glare, making navigation and infotainment unreadable. At night, the same screens may generate dazzling reflections, disturbing driver vision and raising safety concerns. In addition, some large-format displays exhibit color distortion and limited viewing angles—brightness drops dramatically and colors shift when viewed from the side.

For users, the display is the “first visual impression” of the cockpit. Any issues such as reflection, uneven colors, or reduced clarity directly weaken the premium and high-tech perception of the vehicle. For automakers, these seemingly minor details translate into higher complaint rates, increased warranty claims, and potential damage to vehicle reputation and sales.

2. The Hidden Challenge: Optical Coating as the Bottleneck

When confronted with display issues, many automakers first look at the glass substrate or module design, while often overlooking a critical factor—optical coating. Simply put, optical coatings enable reduced reflection, enhanced transmittance, improved color saturation, and superior durability by depositing multi-layer nanometer-scale films onto glass surfaces. In other words, coating quality directly determines the final display performance.

In traditional automotive displays, coating requirements were relatively simple—fewer layers, less complexity, and minimal process sensitivity. But with today’s NEV large-format displays, the situation is dramatically different, presenting two core challenges:

2.1 Large-Area Coating: Uniformity Difficulties

Automotive displays now commonly exceed one meter in width, with some models surpassing 1.5 meters. Achieving uniform coating thickness and stable film properties across such large substrates is highly demanding. Conventional coating systems struggle with large-area deposition, often resulting in thickness variations between the center and edges, leading to inconsistent optical performance across the screen.

2.2 Multi-Layer Stacks: Exponential Process Complexity

To meet increasing user demands for premium display quality, NEV large-format screens require significantly more coating layers. While traditional small displays used just 2–3 layers to achieve basic performance, today’s high-end displays demand 8–12 layers, with some exceeding 14. The more layers required, the more exponentially complex the coating process becomes—demanding higher precision, tighter process stability, and greater repeatability. Conventional systems often suffer from poor interlayer adhesion and performance degradation in multi-layer stacks, falling short of the stringent requirements of modern automotive displays.

3. The Breakthrough: Zhenhua Vacuum Large-Area Optical Coating Solution

For automakers, the only way to truly solve these challenges is by selecting a coating solution that ensures uniformity across large glass substrates, supports complex multi-layer stacks, and delivers consistent process stability.

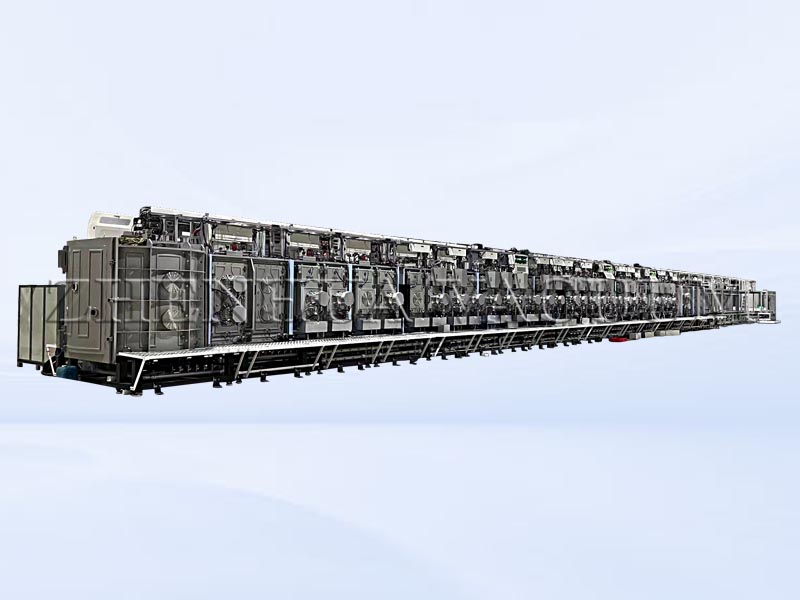

To this end, Zhenhua Vacuum’s large-area optical coating production line has become a proven solution—already in operation with multiple leading OEMs, providing robust and reliable process support for smart cockpit displays. Designed specifically for oversized optical glass, the system delivers three key advantages:

Large-Area Optical Coating Production Line

Core Advantages:

3.1 Capable of mass production of oversized optical glass up to 1600mm × 630mm.

3.2 High throughput with continuous coating cycle times of 50 seconds, fully compatible with robotic and automated handling systems.

3.3 Superior film performance with precision multi-layer optical stacks—up to 14 layers with excellent repeatability and uniformity.

Application Fields: Smart rearview mirrors, center infotainment panels, and cover glass for touchscreens.

Conclusion

The evolution of smart cockpit displays is not simply about “bigger is better,” but about the balance of size and quality. When glare, reflection, and color distortion become bottlenecks limiting user experience, optical coating technology emerges as the decisive factor for competitive differentiation.

With its “large-format coverage, high-efficiency throughput, and precision performance control,” Zhenhua Vacuum’s large-area optical coating production line provides automakers with a solid foundation for premium display performance. It not only resolves today’s mass-production challenges but also ensures scalability for future upgrades.

—This article was published by vacuum coating equipment manufacturer Zhenhua Vacuum

Post time: Sep-29-2025