No.1 Application Scenarios: Comprehensive Upgrade of Large-Size Glass for Intelligent Cockpits

With the rapid adoption of intelligent cockpits, in-vehicle displays and glass components are becoming increasingly larger and more integrated, including:

CMS / Smart Rearview Mirrors, Central Control Panels, Touch Display Glass Cover Lenses

These components are required not only to deliver high-definition visual performance and responsive touch interaction, but also to provide optical and durability functions such as anti-glare, scratch resistance, and anti-fingerprint performance. As a result, significantly higher requirements are imposed on optical coating processes and equipment capabilities.

No.2. Market Challenges: Coating Uniformity Issues Driven by Increasing Substrate Size

1. Enlarged Substrates Expose Uniformity Limitations

Conventional coating systems struggle to achieve uniform film thickness over large-area glass substrates. Thickness deviations between the center and edges often lead to non-uniform brightness, contrast, and color performance across the display surface, directly impacting overall visual quality and user experience.

2. Limited Throughput, Poor Compatibility with Automated Lines

Traditional batch-type coating equipment typically involves frequent loading, unloading, and intermediate handling steps, resulting in long cycle times per substrate. This makes it difficult to seamlessly integrate with robotic handling systems and fully automated production lines.

3. Complex Multilayer Stacks, Difficulties in Stable Mass Production

Intelligent cockpit glass often requires multi-layer functional optical stacks, placing strict demands on film thickness control, chromatic consistency, and batch-to-batch repeatability. Conventional processes face challenges in maintaining long-term stability and yield when producing complex multilayer coatings at scale.

No.3 Zhenhua Vacuum Solution: Optical Coating System for Large-Size Intelligent Cockpit Glass

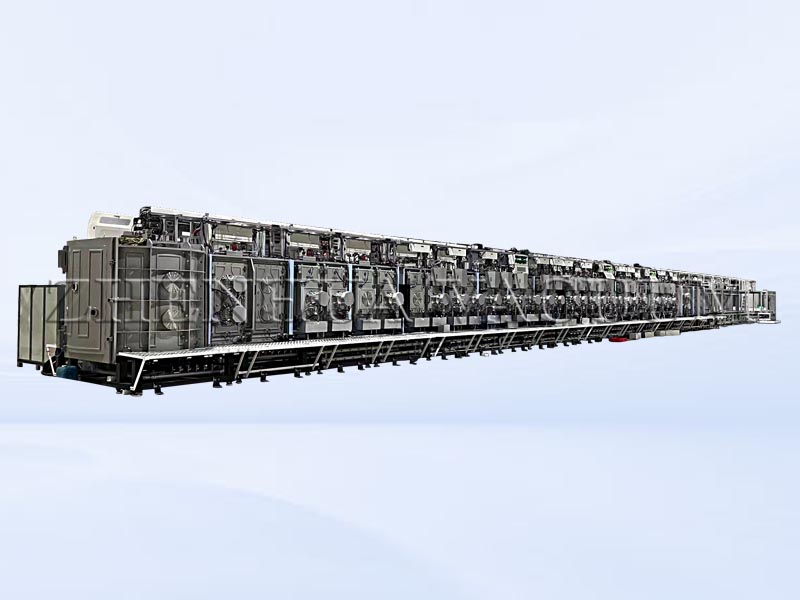

To address the requirements of smart rearview mirrors, central control panels, and touch display glass cover lenses, Zhenhua Vacuum has developed a Large-Area Planar Optical Coating Production Line.

From system architecture and substrate transport design to process window optimization, the production line is specifically engineered for high-volume manufacturing of large-size optical glass. It enables stable integration with automated production lines operated by automotive OEMs and Tier-1 suppliers, delivering a high-efficiency, high-consistency optical coating solution.

No.4 Equipment Advantages: Enabling Mass Production of Large-Area Optical Glass

Large-Area Planar Optical Coating Production Line

Advantages:

Capable of mass production for optical glass substrates up to 1600 mm × 630 mm

Continuous coating cycle time of 50 seconds, fully compatible with robotic handling and automated loading/unloading systems

Excellent film performance: supports precision deposition of complex optical stacks with up to 14 functional layers, ensuring high repeatability and process stability

Typical Applications:

Smart rearview mirrors, central control panels, touch display glass cover lenses, and other intelligent cockpit glass components.

–This article was published by vacuum coating equipment manufacturer Zhenhua Vacuum

Post time: Dec-11-2025