No.1 Accelerated Adoption of Optical Modules, Rising Process Demands

As intelligent cockpits rapidly evolve, visual modules are becoming standard components across modern vehicles. From central control displays and co-pilot entertainment screens to CMS (Camera Monitoring Systems) and DMS (Driver Monitoring Systems), the system complexity of in-vehicle electronics continues to grow. A common foundation among them is the need for reliable optical thin film coatings.

Unlike conventional small-size displays, automotive optical modules must meet stringent demands in size, structural complexity, and environmental resistance. As a result, the film quality on components such as cover glass, filters, and protective sheets has become a key factor affecting vehicle reliability and user experience.

No.2 Complex Multi-Layer Structures Create Yield Pressure

The current generation of automotive optical modules has moved beyond single-layer coatings toward sophisticated multi-layer stacks that integrate AR (Anti-Reflection), AF (Anti-Fingerprint), and IR-Cut functional films. Each layer must meet its own performance specifications while collectively forming a stable optical system. This raises significant challenges in process control and equipment stability.

Traditional electron beam (EB) evaporation systems struggle under these demands. As the number of layers increases, issues such as film thickness deviation, interfacial instability, and non-uniformity across the substrate become increasingly prominent. Even slight variations in deposition rate can shift the optical spectrum, compromising transmittance or reflectance, and causing module malfunctions.

This is especially critical in large-format glass substrates, where edge thickness non-uniformity often leads to partial rejection of otherwise usable panels, significantly reducing overall line yield.

Batch-type systems further compound the issue. Their limited responsiveness to multi-process switching and tight delivery schedules makes them ill-suited for customized, high-mix automotive requirements. As automotive production cycles accelerate and cost pressures mount, problems such as process fluctuation, inconsistent performance, reduced yield, and increased rework not only raise production costs but also amplify warranty and after-sales risks.

In short, continuing to rely on legacy equipment in today’s automotive optical module production is no longer just an efficiency bottleneck — it poses systemic risks across quality, yield, delivery, and cost dimensions.

No.3 Returning to the Core: A System-Level Approach to Size, Performance, and Efficiency

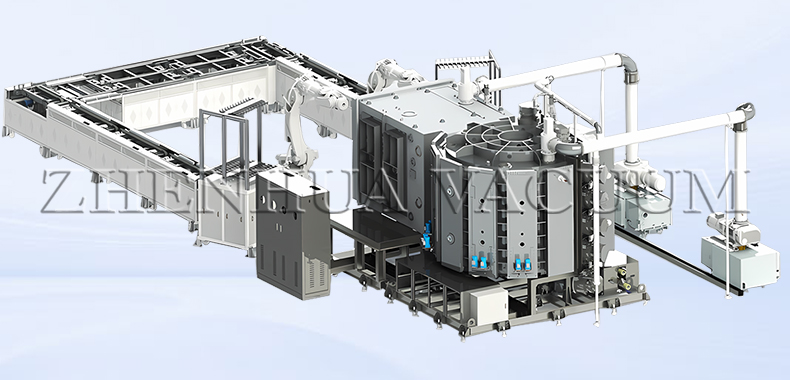

To address these evolving challenges, Zhenhua Vacuum has launched the SOM-2550 Sputtering Optical Inline Coater, engineered specifically for high-precision optical module manufacturing in the intelligent cockpit era.

The equipment targets three key bottlenecks — size compatibility, multilayer control, and throughput — through integrated process and system-level optimization:

Large-Format Compatibility

With an effective coating height of up to 1100 mm and a maximum coating area of 8 m², the system accommodates both oversized and irregularly shaped automotive glass substrates. Film uniformity is controlled within ±1%, ensuring reliable performance across cover glass, camera windows, and smart mirror substrates.

Multi-Functional Stack Deposition

The system supports continuous deposition of AR, NCVM (Non-Conductive Vacuum Metallization), AF, and IR-CUT films, with precise control across multiple target materials and segment parameters. The resulting coatings are dense, with optical transmittance reaching up to 95% and surface hardness up to 9H — meeting the dual requirements of optical clarity and mechanical durability for high-end automotive components.

High-Efficiency Inline Production

Featuring fully automated loading/unloading and intelligent monitoring modules, the system enables 24/7 continuous operation. Its production capacity is 3.2 times that of traditional EB systems, significantly reducing unit costs while maintaining tight process windows and inter-batch consistency.

No.4 Final Thoughts

As the intelligent cockpit evolves toward a screen-centric, sensor-integrated, and functionally converged ecosystem, vacuum coating systems are no longer peripheral tools — they are strategic assets that directly shape module performance and production cadence.

Zhenhua Vacuum remains committed to advancing magnetron sputtering process capabilities and equipment system integration. Focused on high-value applications such as smart mirrors, cover glass, camera modules, and HUDs, we provide high-efficiency, high-stability, and scalable vacuum coating solutions — enabling customers to build the next-generation foundation for intelligent cockpit manufacturing.

— This article was published by intelligent cockpit vacuum coating manufacturer Zhenhua Vacuum

Post time: Jul-16-2025