In modern life, optical coating technology has become an invisible yet essential part of many products—from prescription lenses to smartphone cameras, from automotive head-up displays (HUD) to energy-saving architectural glass. As a functional, technical, and aesthetic surface treatment method, optical coatings are driving progress in display quality, imaging performance, energy efficiency, and smart manufacturing. Among various coating solutions, multilayer optical coatings have emerged as the mainstream technology thanks to their exceptional performance tunability.

1. Overview: Optical Coating—The “Invisible Craft” of Light Control

Optical coating refers to the deposition of one or more thin-film layers on transparent or semi-transparent substrates to control light behavior—reflection, transmission, and absorption. These layers typically consist of materials with high or low refractive indices, such as metal oxides, fluorides, or nitrides, with film thicknesses ranging from tens to hundreds of nanometers.

The principle is based on optical interference: when light encounters multiple film interfaces, interference caused by phase differences can enhance or suppress specific wavelengths. Engineers leverage this effect to precisely adjust reflectivity, transmittance, and color rendering to meet diverse optical requirements.

2. Why Move Toward Multilayer Coatings?

In early applications, single-layer coatings—such as a magnesium fluoride (MgF₂) layer for anti-reflection—were commonly used. However, such designs only optimize performance at one specific wavelength or incident angle, limiting their effectiveness under broadband or multi-angle lighting conditions.

As optoelectronic components have evolved, the need for integrated functionalities—anti-reflection, color enhancement, thermal control, etc.—has outpaced what single-layer films can deliver. This paved the way for multilayer optical coatings, which stack alternating high- and low-index layers to create complex interference structures, enabling broader spectral response and angular stability.

Key Advantages of Multilayer Optical Coatings

Compared to single-layer designs, multilayer coatings offer superior optical performance and broader application potential:

Enhanced Control of Reflection and Transmission

With tailored interference structures, reflectance can be reduced to <0.2% or increased to >99%, ideal for anti-reflective lenses and high-reflectivity laser mirrors.

Broadband Spectral Coverage

By optimizing layer thicknesses and refractive index contrasts, coatings can span UV, visible, and NIR ranges to achieve efficient filtering or transmission.

Multifunctional Integration

Coatings can incorporate anti-glare, heat rejection, polarization, photochromic, or other functions—enhancing overall product performance and user experience.

High Environmental Stability

Using magnetron sputtering and other vacuum processes, films exhibit excellent adhesion and chemical resistance, making them suitable for harsh environments in automotive, aerospace, and outdoor use.

Applications: From Lenses to Smart Vehicles

Consumer Electronics

Multilayer coatings are widely used in camera lens modules, tablet displays, and blue light blocking glasses to improve clarity and reduce glare.

Automotive Optics

Applied to HUD mirrors, smart rearview mirrors, and lighting optics, these coatings improve reflection efficiency, visual clarity, and driving safety.

Architectural Glass

Low-emissivity (Low-E) glass typically uses silver-based multilayer coatings to reflect infrared radiation while maintaining visible light transmittance for energy conservation.

Precision Instruments & Optical Communication

In telescopes, laser systems, and fiber-optic devices, multilayer films optimize signal strength, stabilize wavelengths, and minimize power loss.

Cosmetics & Decorative Packaging

On perfume bottles or makeup containers, multilayer interference coatings create dynamic color-shifting effects, delivering a unique visual identity and luxury appeal.

3. ZhenHua Vacuum’s Optical Film Coating Solutions-Large-scale plate PVD Optical Coating Inline Coater

Key Features:

Supports large-format substrates up to 1600mm × 630mm

50s cycle time for continuous coating, compatible with robotic automation

Up to 14-layer precision multilayer stacks with high reproducibility

Applications: Smart rearview mirrors, automotive center displays, touch screen cover glass, camera lenses, and optical windows.

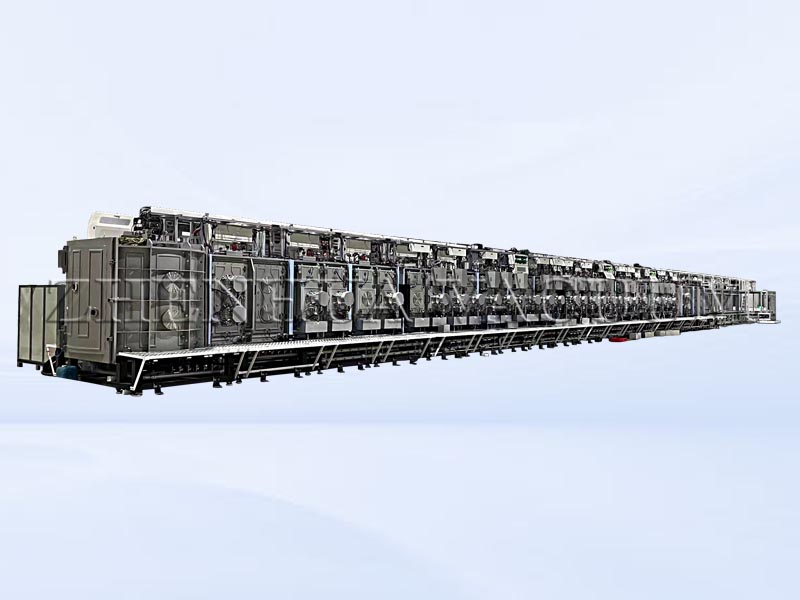

Inline Magnetron Sputtering Optical Coating System

Key Features:

Coating area up to 8 m², 3.2× productivity compared to traditional e-beam coating systems

Film thickness up to 1100mm, uniformity within ±1%

Visible light transmittance up to 99%

9H ultra-hard AR + AF coatings, scratch-resistant and durable

Applications: AR/NCVM + DLC + AF coatings for smart mirrors, in-vehicle displays, touch panels, camera glass, IR-CUT filters, and facial recognition optics.

Conclusion: A Core Process for the Future of Visual Technology

From basic visual enhancement to high-end functional integration, multilayer optical coating is no longer just a surface treatment—it’s a core process enabling the advancement of photonics and optoelectronics. As industries demand ever-higher optical performance, this technology will play an increasingly vital role across smart devices, automotive systems, new displays, and green building materials.

For equipment manufacturers, brand owners, and design engineers alike, mastering and leveraging this technology is key to delivering high-performance, high-value-added optical products in a competitive global market.

—This article was published by Optical Film vacuum coating equipment manufacturer Zhenhua Vacuum

Post time: Jun-30-2025